Carbon cloth-supported nickel-cobalt-oxygen nanosheet composite material and its preparation method and electrode application

A technology of composite materials and nanosheets, applied in the field of metal-air battery electrocatalysis, can solve the problems of low activity, single active site, poor conductivity, etc., and achieve the effect of improving electrode performance, reducing quality, and simple experimental steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The preparation method of the nickel-cobalt-oxygen porous nanosheet composite material of the present invention comprises the following steps:

[0036] 1), dissolve cobalt nitrate and nickel nitrate in the deionized water of deoxygenation, stir and dissolve in gas protective atmosphere, obtain mixed salt solution;

[0037] 2), stir the sodium hydroxide solution and mixed salt solution at room temperature, then centrifuge out the precipitate, wash with deionized water and absolute ethanol;

[0038] 3), vacuum-drying the precipitate obtained in step 2) to obtain a precursor, and sintering to obtain a nickel-cobalt-oxygen nanosheet composite material catalyst that can be used for the cathode of an air battery.

[0039] The dosage of cobalt nitrate and nickel nitrate is 3~5mmol and 12~20mmol;

[0040] The amount of deionized water is 50mL;

[0041] Described step 1) protective gas gas is N 2 , O 2 Or air; the stirring speed is 200~600r / min, the time is 0.5~1.5h, and the...

Embodiment 1

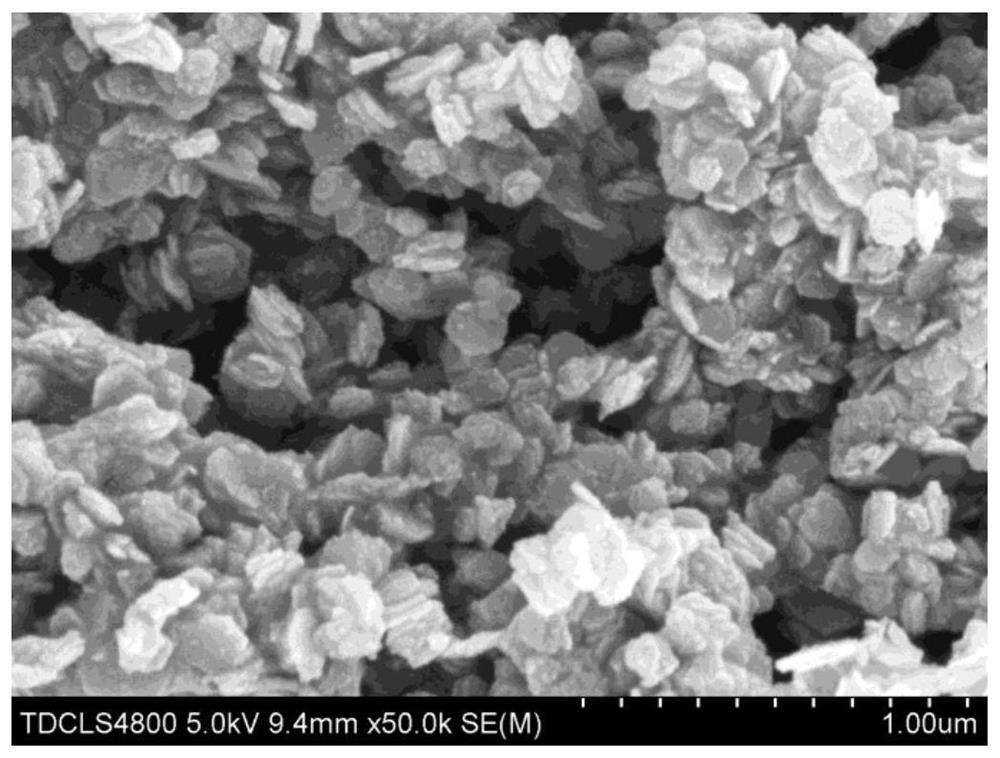

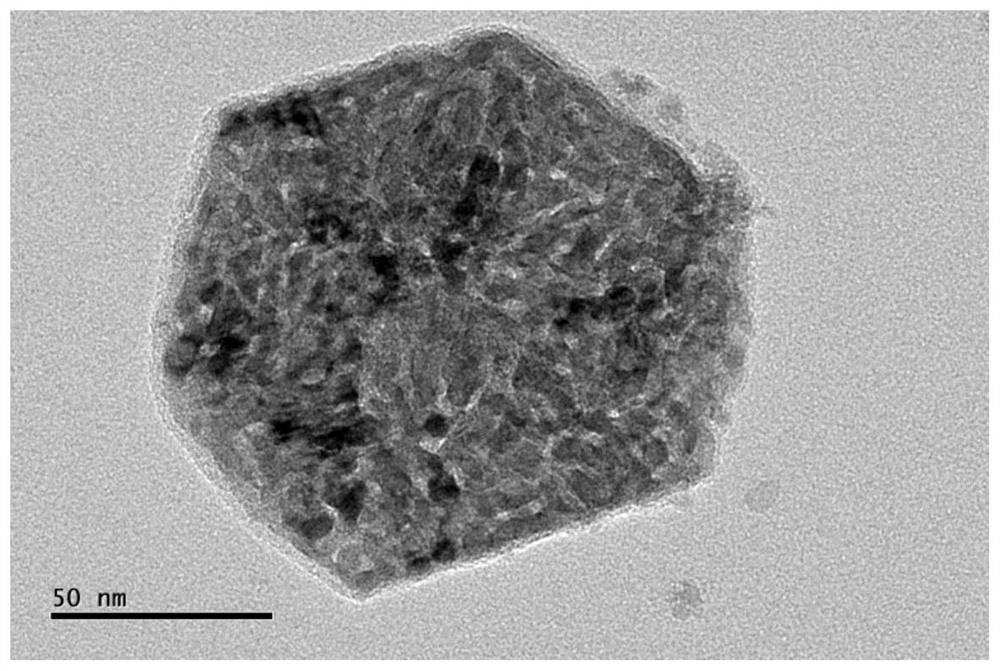

[0045] Dissolve 12 mmol of cobalt nitrate and 3 mmol of nickel nitrate in 50 mL of deoxygenated deionized water under N 2 Stir in a protective atmosphere for 1.5 h, and the stirring speed is 200 r / min to obtain a mixed salt solution. 25mL of 2M NaOH was added to the mixed salt solution, stirred evenly, and the obtained dark green precipitate was washed three times with deionized water and absolute ethanol, then placed in a vacuum oven, and dried under vacuum at 30°C for 10h to obtain the precursor. The above precursor is put into a well-type muffle furnace for sintering, the heating rate is 3-4 °C / min, the holding temperature is 300 °C, the holding time is 3h, and it is cooled under air cooling to obtain elongated pores with a surface of 5-20 nanometers. , hexagonal sheet-shaped nickel-cobalt-oxygen nanocomposite materials with a diameter of 130-150 nanometers.

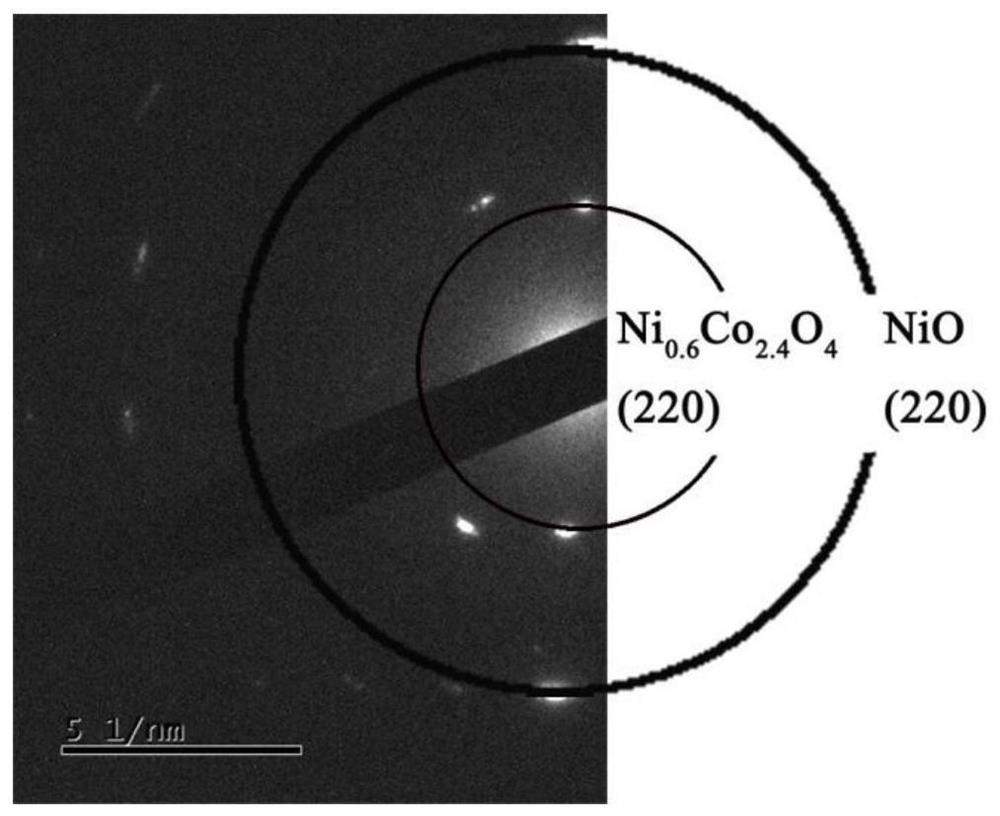

[0046] The diffraction patterns of the nickel-cobalt-oxygen porous nanosheet composites prepared in the above exam...

Embodiment 2

[0050] Dissolve 16 mmol of cobalt nitrate and 4 mmol of nickel nitrate in 50 mL of deoxygenated deionized water under N 2 Stir for 1 h in a protective atmosphere at a stirring speed of 400 r / min to obtain a mixed salt solution. 25mL of 2.7M NaOH was added to the mixed salt solution, stirred evenly, and the obtained dark green precipitate was washed three times with deionized water and absolute ethanol, then placed in a vacuum oven, and dried under vacuum at 25°C for 15h to obtain the precursor. The above-mentioned precursors are put into a well-type muffle furnace for sintering, the heating rate is 4-5 °C / min, the holding temperature is 325 °C, the holding time is 3h, and it is cooled under air-cooling conditions to obtain surface 5-20 nanometer long pores with a diameter of 130-140 nanometer hexagonal sheet-shaped nickel-cobalt-oxygen composite cathode catalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com