Hinged cubic press first-stage pressure increasing device

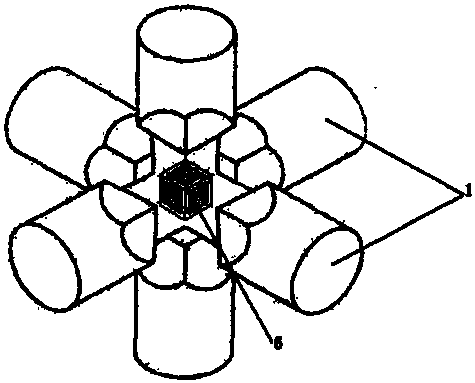

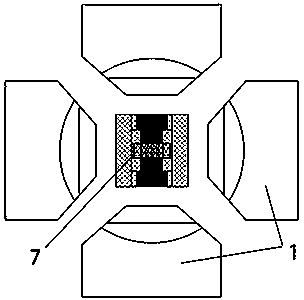

A technology of a six-sided top press and a high-pressure device, which is applied in the method of using atmospheric pressure to chemically change substances, the process of applying ultra-high pressure, chemical instruments and methods, etc., can solve problems such as low pressure and achieve pressure loading. Small, low probability of damage, excellent overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

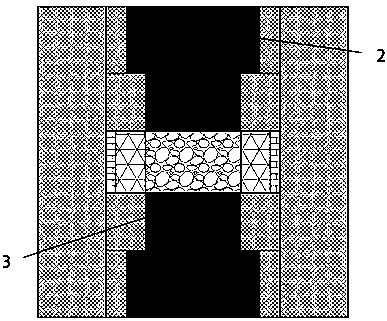

[0031] (1) Assembly of sealing pressure unit: put Φ 外径 =16.23mm, Φ 内径=6mm sealed pressure insulation cylinder into Φ 外径 =18.23mm, Φ 内径 =16.23mm sealing pressure metal cylinder, and then put the heating device into the sealing pressure insulation cylinder in turn to assemble the sealing pressure unit.

[0032] (2) Assembly of booster unit: Put Φ=6mm, h=6mm tungsten carbide booster column into Φ 外径 =18.23mm, Φ 内径 =16.23mm in a pyrophyllite ring, and then wrap a tungsten carbide booster plug with a diameter of Φ=14mm and h=7mm in a pyrophyllite ring. Finally, the booster plug and the booster column are combined to form a booster unit.

[0033] (3) Assembling of pressurization-insulation pre-sealed high-pressure device: put the unit assembled in (1) (2) into the pyrophyllite pressure transmission medium, and the order of placement is: pressurization unit, sealing unit, booster unit pressure unit. Finally, a symmetrical assembly with the sealing unit as the axis of symmetry ...

Embodiment 2

[0037] (1) Assembly of sealing pressure unit: put Φ 外径 =16.23mm, Φ 内径 =10mm sealed pressure insulation cylinder into Φ 外径 =18.23mm, Φ 内径 =16.23mm sealing pressure metal cylinder, and then put the heating device into the sealing pressure insulation cylinder in turn to assemble the sealing pressure unit.

[0038] (2) Assembly of booster unit: Put Φ=10mm, h=6mm tungsten carbide booster column into Φ 外径 =18.23mm, Φ 内径 =10mm in a pyrophyllite ring, and then wrap a tungsten carbide booster plug with a diameter of Φ=14mm and h=7mm in a pyrophyllite ring. Finally, the booster plug and the booster column are combined to form a booster unit.

[0039] (3) Assembling of pressurization-insulation pre-sealed high-pressure device: put the unit assembled in (1) (2) into the pyrophyllite pressure transmission medium, and the order of placement is: pressurization unit, sealing unit, booster unit pressure unit. Finally, a symmetrical assembly with the sealing unit as the axis of symmetry ...

Embodiment 3

[0044] (1) Assembly of sealing pressure unit: put Φ 外径 =16.23mm, Φ 内径 =10mm sealed pressure insulation cylinder into Φ 外径 =18.23mm, Φ 内径 =16.23mm sealing pressure metal cylinder, and then put the heating device into the sealing pressure insulation cylinder in turn to assemble the sealing pressure unit.

[0045] (2) Assembly of booster unit: Put Φ=10mm, h=6mm tungsten carbide booster column into Φ 外径 =18.23mm, Φ 内径 =10mm in a pyrophyllite ring, and then wrap a tungsten carbide booster plug with a diameter of Φ=14mm and h=7mm in a pyrophyllite ring. Finally, the booster plug and the booster column are combined to form a booster unit.

[0046] (3) Assembling of pressurization-insulation pre-sealed high-pressure device: put the unit assembled in (1) (2) into the pyrophyllite pressure transmission medium, and the order of placement is: pressurization unit, sealing unit, booster unit pressure unit. Finally, a symmetrical assembly with the sealing unit as the axis of symmetry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com