Preparation method of precious metal loaded Bi2WO6 visible light photocatalyst

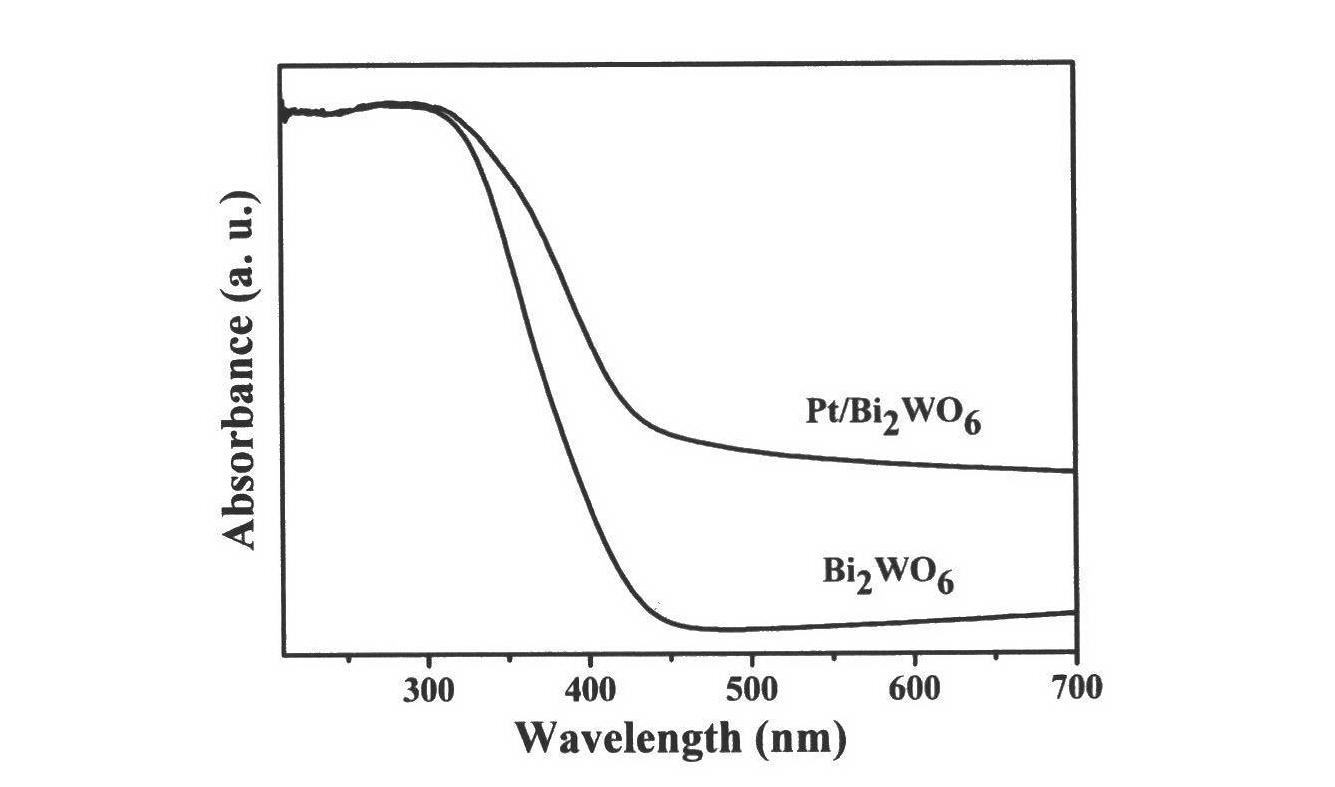

A noble metal and visible light technology, applied in the field of photocatalysis, can solve the problems of limited large-scale application and limited visible light absorption, and achieve the effect of improving visible light catalytic activity, increasing the absorption range, and facilitating recycling and reuse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

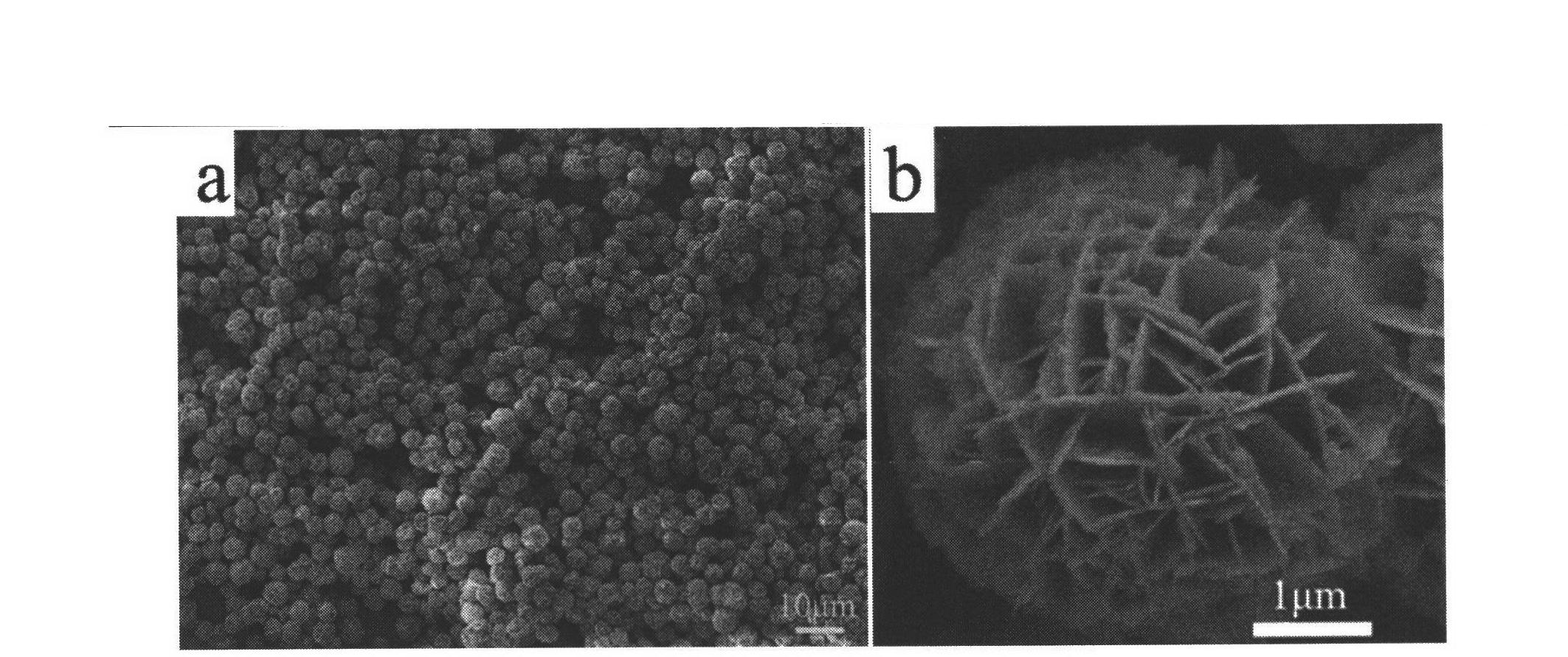

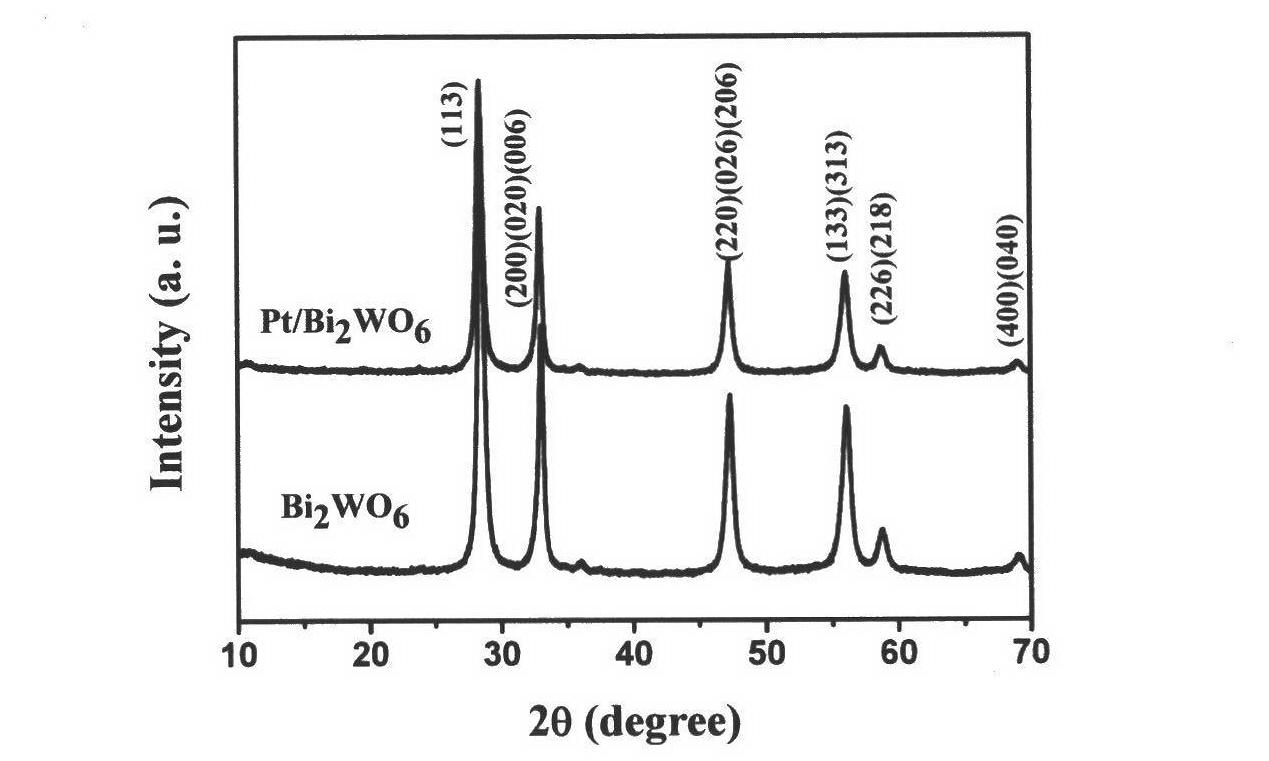

[0020] (2) flower-like grade Bi 2 WO 6 Preparation: the above Bi 2 WO 6 Transfer the precursor suspension into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, react at 120-240°C for 10-20h, centrifuge the obtained product, and dry it in vacuum at 50-100°C to obtain a flower-shaped grade Structural Bi 2 WO 6 catalyst of light.

[0021] (3) the flower-like hierarchical structure Bi obtained in step (2) 2 WO 6 Disperse in a mixed solvent of methanol and water, control the volume ratio of methanol to water at 1:3 to 3:1, stir evenly, and then add different amounts of chloroplatinic acid, chloroauric acid, silver nitrate and other acids containing precious metals or Salt, stir evenly, and ultrasonically disperse for 10-120 minutes to obtain a uniformly dispersed suspension.

[0022] (4) Place the suspension obtained in the above step (3) under an ultraviolet lamp, stir while illuminating, illuminate for 10-240min, stop illuminating, let stand for 30min,...

Embodiment example 1

[0024] Embodiment example 1: a kind of noble metal supported Bi of the present invention 2 WO 6 The preparation method of visible light catalyst comprises the following steps:

[0025] (1) Preparation of Bi 2 WO 6 Precursor solution: Dissolve 2mmol of bismuth nitrate in 5ml of acetic acid to form a transparent solution, add 20mL of 0.05mol / L sodium tungstate solution under stirring, and stir for 0.5h to obtain Bi 2 WO 6 Precursor white suspension.

[0026] (2) flower-like grade Bi 2 WO 6 Preparation: the above Bi 2 WO 6 The precursor suspension was transferred into a 50mL stainless steel autoclave lined with polytetrafluoroethylene, reacted at 180°C for 15h, cooled naturally to room temperature, and the resulting product was centrifuged and dried in vacuum at 50°C to obtain a flower-like hierarchical structure Bi 2 WO 6 catalyst of light.

[0027] (3) Take the flower-like hierarchical structure Bi obtained in step (2) 2 WO 6 150mg was dispersed in a mixed solvent...

Embodiment 2

[0030] Implementation example 2: a kind of noble metal supported Bi of the present invention 2 WO 6 The preparation method of visible light catalyst comprises the following steps:

[0031] (1) Preparation of Bi 2 WO 6 Precursor solution: Dissolve 1mmol of bismuth nitrate in 5ml of acetic acid to form a transparent solution, add 10mL of 0.05mol / L sodium tungstate solution under stirring, and stir for 0.5h to obtain Bi 2 WO 6 Precursor white suspension.

[0032] (2) flower-like grade Bi 2 WO 6 Preparation: the above Bi 2 WO 6 The precursor suspension was transferred to a 50mL stainless steel autoclave lined with polytetrafluoroethylene, reacted at 170°C for 20h, cooled naturally to room temperature, and the resulting product was centrifuged and dried in vacuum at 50°C to obtain a flower-like hierarchical structure Bi 2 WO 6 catalyst of light.

[0033] (3) Take the flower-like hierarchical structure Bi obtained in step (2) 2 WO 6 150mg was dispersed in a mixed solve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com