Process for producing crude selenium powder

A production process, crude selenium technology, applied in the field of mechanical crushing, can solve the problems of difficult product particle size to meet the industry standard of selenium powder, difficulty in screening selenium powder, equipment bonding, etc., to reduce equipment maintenance costs, improve crushing and screening Efficiency, the effect of avoiding sticking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The equipment used in the embodiment is all equipment purchased from the market.

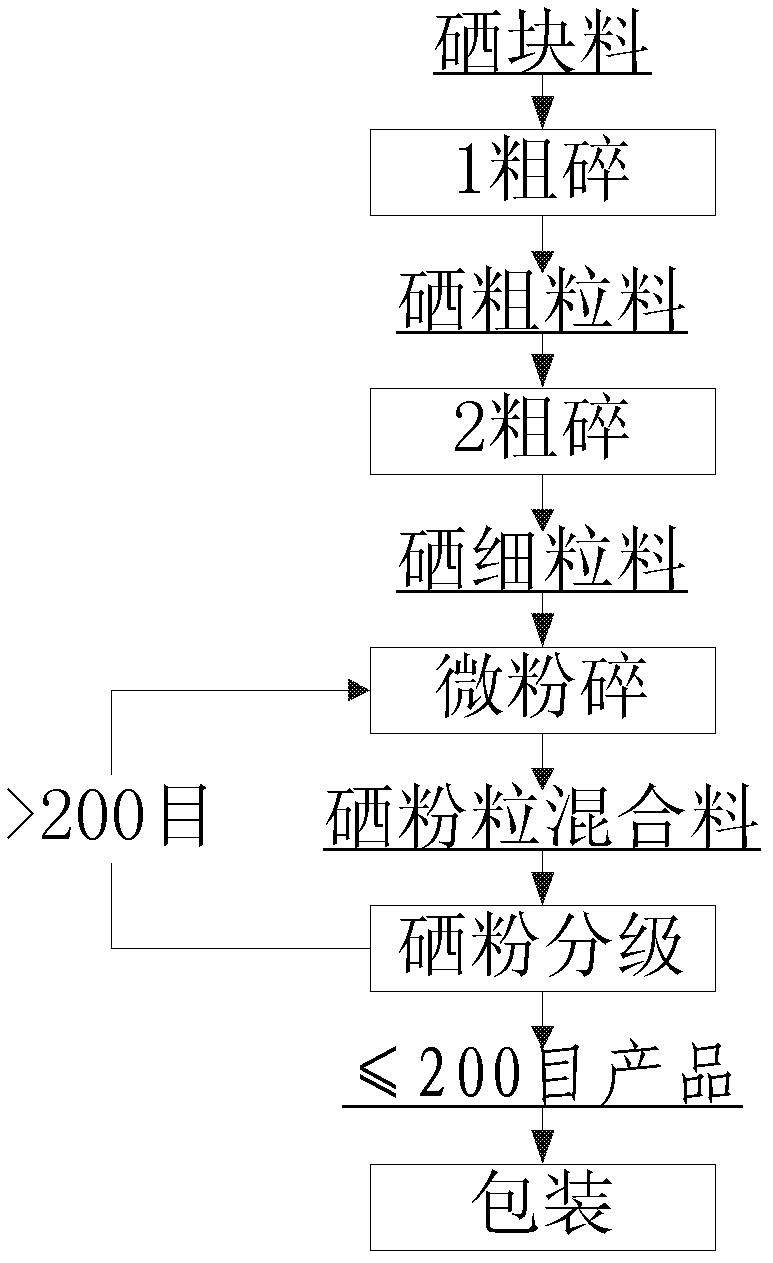

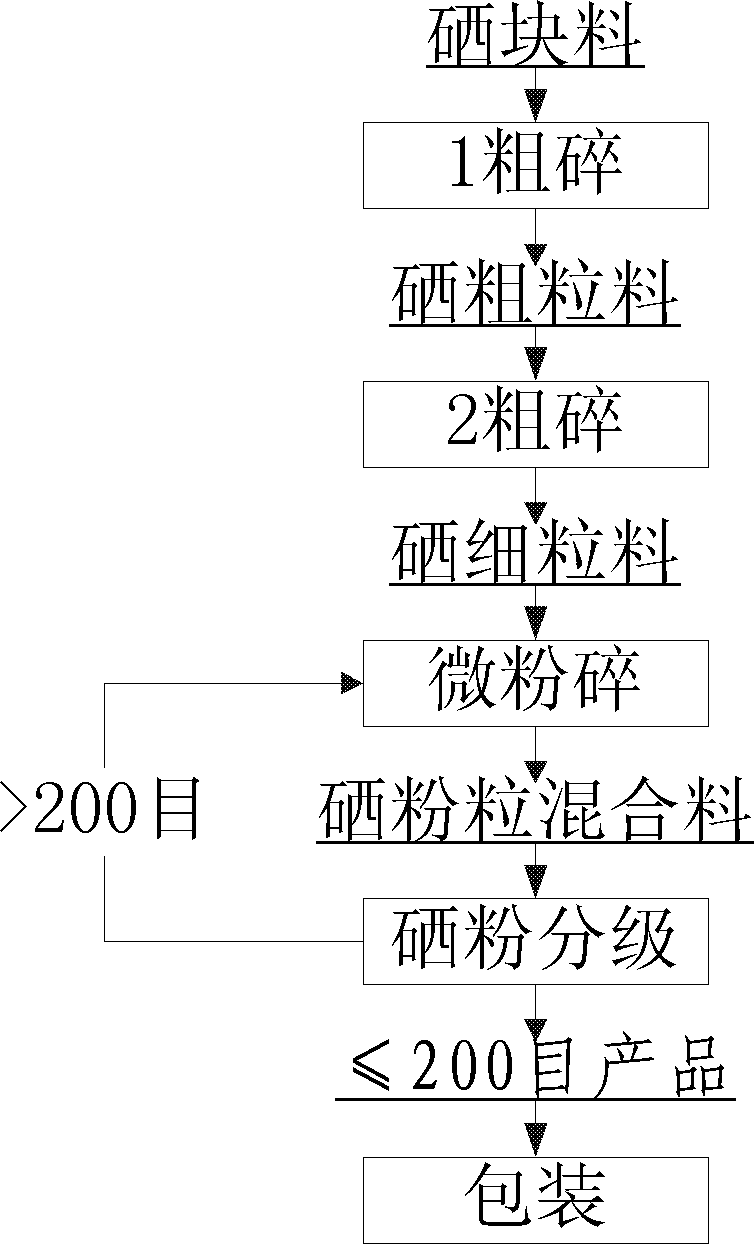

[0013] Coarse selenium powder production technique of the present invention, concrete steps are as follows:

[0014] 1. Crush the selenium ingots into selenium lumps with a particle size of <30mm. The selenium lumps enter the coarse crusher for primary crushing. The particle size of secondary coarsely crushed selenium particles is less than 3mm, and the feed rate of selenium particles entering the coarse crusher and pulverizer is controlled at 150kg / h or 220kg / h or 300kg / h.

[0015] 2. Selenium particles with a particle size of <3mm enter the micro pulverizer for micro pulverization. The processing capacity of the micro pulverizer is controlled at 30kg / h or 45kg / h or 60kg / h. The pulverized selenium powder is screened with a 200-mesh vibrating sieve 100% of the selenium powder product passes through a 200-mesh sieve (particle size<0.074mm), 80% passes through a 400-mesh sieve (particle si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com