Preparation method for high-strength bamboo structural material suitable for construction and bridgework structures

A technology of bridge engineering and structural materials, applied in the field of building materials and building structures, can solve problems that cannot meet the requirements of physical and mechanical properties, discreteness, layer geometry, interface property design and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The preparation method of high-strength bamboo structure material,

[0043] 1. The felled adult bamboo is degreened and yellowed mechanically, and dried in a steam oven at a constant temperature so that the moisture content is about 10%.

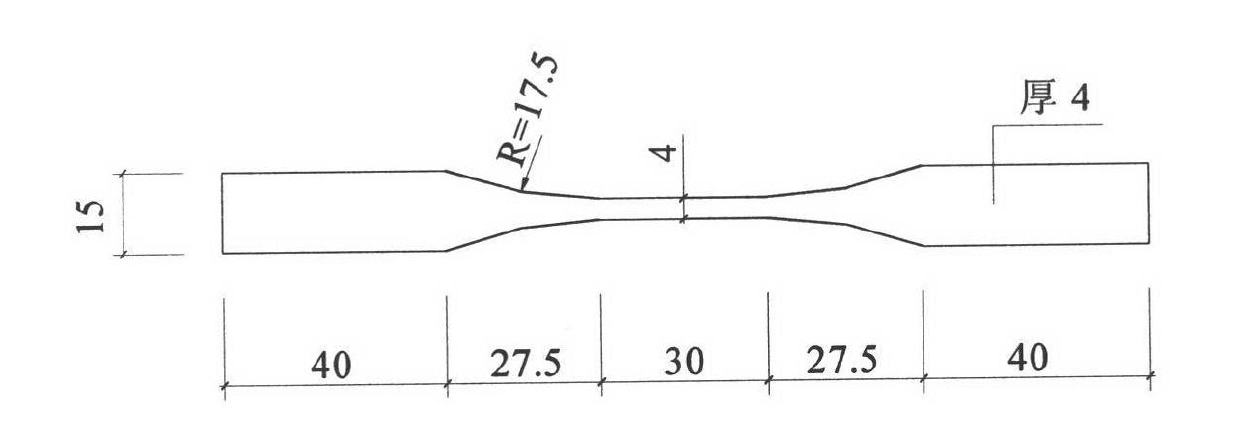

[0044]2. Randomly select not less than 3% of each batch of raw materials, and the total number of bamboos is not less than 60 to make a test block of 15mm×15mm×4mm, put the test block into a beaker with an appropriate amount of water, and place it in DK -In the S24 type electric heating constant temperature water bath, cook continuously at a temperature of 100°C for 24 hours for softening treatment, then dry in the air, and make slices with a sliding microtome. The microscopic image of the test piece was taken by an electron microscope, and the microscopic structure was studied by image processing technology, and the volume ratio of the vascular bundles of the original bamboo was obtained r f and spatial distribution.

[0045] 3. Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com