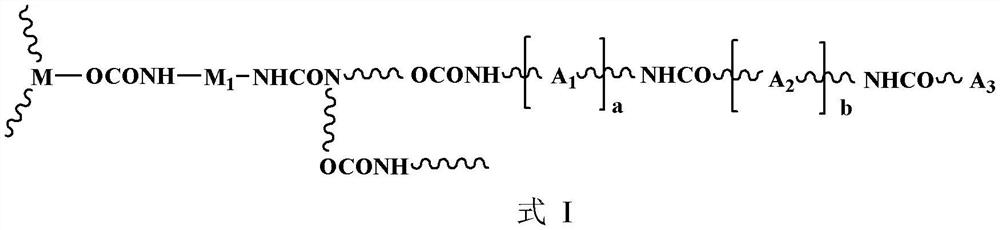

A kind of hyperbranched polyurethane water-repellent finishing agent and its preparation method and application

A technology of hyperbranched polyurethane and water-repellent finishing, applied in fiber treatment, liquid repellent fibers, plant fibers, etc., can solve the problem of affecting the number of long-chain fatty alcohols inserted, affecting the water-repellent effect, and less branched structure. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

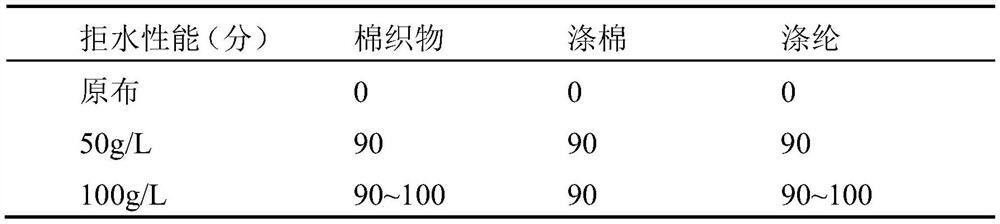

Examples

Embodiment 1

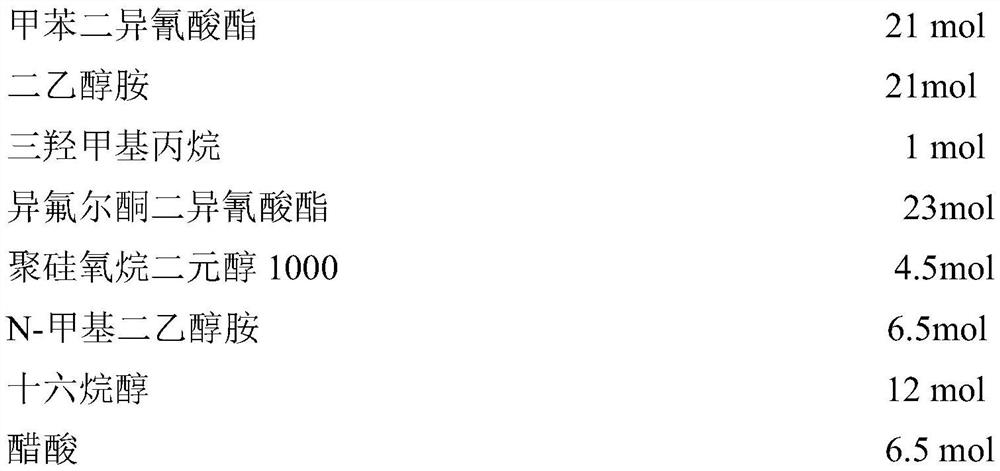

[0050] Formula of hyperbranched polyurethane water-repellent finishing agent:

[0051]

[0052] 1. Preparation

[0053] The raw materials in the above formula are prepared according to the preparation method of the present invention to prepare the hyperbranched polyurethane water-repellent finishing agent.

[0054] Concrete preparation method, the steps are as follows:

[0055] Under the protection of inert gas nitrogen, 21mol toluene diisocyanate and 21mol diethanolamine were reacted in an ice-water bath at -5°C for 0.5h, and then heated to 50°C for another 6h to obtain an -NCO group at one end and -OH at both ends. Group branched prepolymer I, add 1mol trimethylolpropane to prepolymer I, react at 80°C for 2h, and obtain prepolymer II whose outer layer is -OH group; add 23mol isophorone Mix diisocyanate, 4.5mol polysiloxane diol 1000, 6.5mol N-methyldiethanolamine, and 12mol cetyl alcohol evenly, react at 80°C for 2 hours, cool down to 40°C, and obtain a compound with -N...

Embodiment 2

[0063] Formula of hyperbranched polyurethane water-repellent finishing agent:

[0064]

[0065] 1. Preparation

[0066] The raw materials in the above formula are prepared according to the preparation method of the present invention to prepare the hyperbranched polyurethane water-repellent finishing agent.

[0067] The specific preparation method is:

[0068] Under the protection of inert gas nitrogen, 21mol toluene diisocyanate and 21mol diethanolamine were reacted in an ice-water bath at -5°C for 0.5h, and then heated to 50°C for another 6h to obtain an -NCO group at one end and -OH at both ends. Group branched prepolymer I, add 1mol trimethylolpropane to prepolymer I, react at 80°C for 2h, and obtain prepolymer II whose outer layer is -OH group; add 23mol isophorone Mix diisocyanate, 4.5mol polysiloxane diol 1000, 6.5mol dimethylol propionic acid, and 12mol cetyl alcohol evenly, react at 80°C for 2 hours, and cool down to 40°C to obtain -NCO group at one end Prepolyme...

Embodiment 3

[0076] Formula of hyperbranched polyurethane water-repellent finishing agent:

[0077]

[0078]

[0079] 1. Preparation

[0080] The raw materials in the above formula are prepared according to the preparation method of the present invention to prepare the hyperbranched polyurethane water-repellent finishing agent.

[0081] The specific preparation method is:

[0082] Under the protection of inert gas nitrogen, 21mol toluene diisocyanate and 21mol diethanolamine were reacted in an ice-water bath at -5°C for 0.5h, and then heated to 50°C for another 6h to obtain an -NCO group at one end and -OH at both ends. Group branched prepolymer I, add 1mol trimethylolpropane to prepolymer I, react at 80°C for 2h, and obtain prepolymer II whose outer layer is -OH group; add 23mol isophorone Mix diisocyanate, 4.5mol polysiloxane diol 1000, 6.5mol N-methyldiethanolamine, and 12mol docosanol evenly, react at 80°C for 2 hours, and cool down to 40°C to obtain -NCO group at one end Prep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com