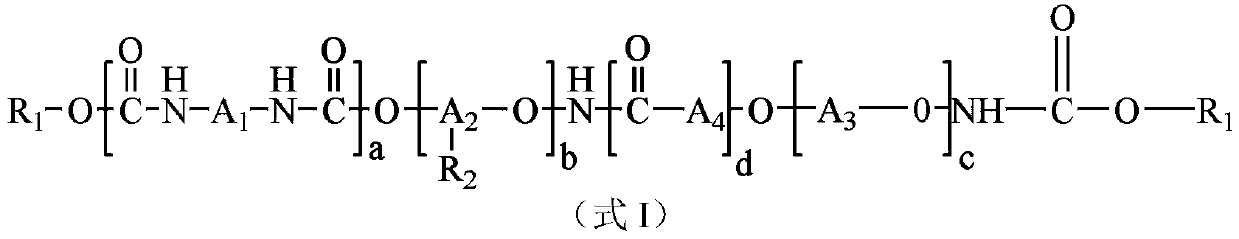

A comb-shaped polyurethane flame-retardant water-repellent finishing agent and its preparation method and application

A technology of water-repellent finishing and polyurethane, which is applied in the direction of flame-retardant fibers, fiber treatment, and liquid-repellent fibers, etc., can solve the problems of poor water resistance, poor flame-retardant and water-repellent synergistic effects, etc., and achieve good flame-retardant effects, Excellent flame retardant and water repellent properties, cheap and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

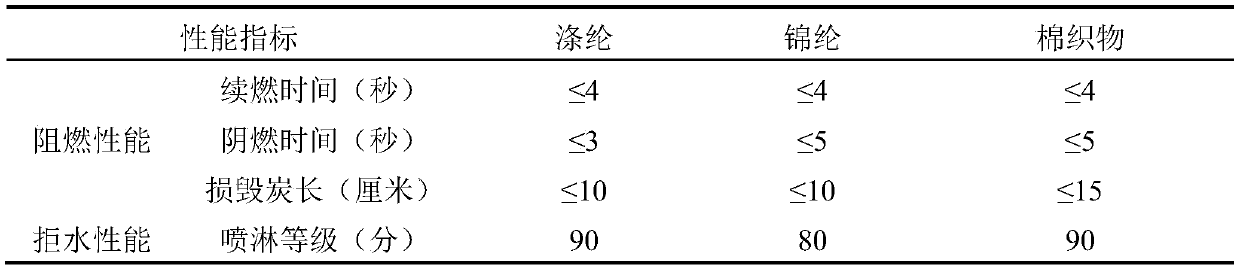

Examples

Embodiment 1

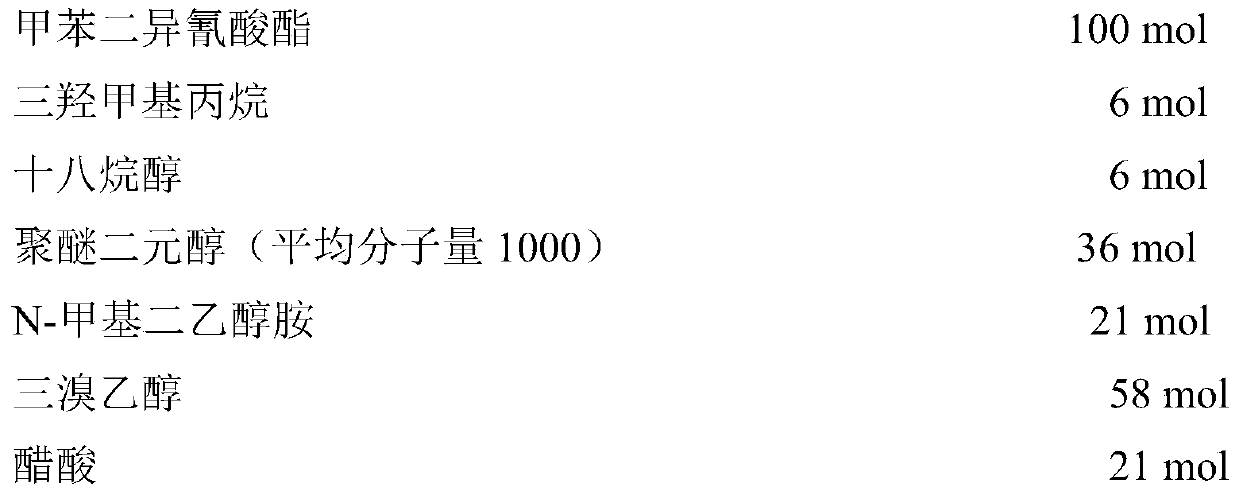

[0061] Comb Polyurethane Flame Retardant Water Repellent Finishing Agent Formula

[0062]

[0063] 1. Preparation

[0064] The raw materials in the above formula are prepared according to the preparation method of the present invention to prepare a comb-shaped polyurethane flame-retardant and water-repellent finishing agent.

[0065] The specific preparation method is as follows: 1 part of dibutyltin dilaurate catalyst is diluted and dissolved with two parts of butanone, and after stirring evenly, a catalyst solution is obtained; under the protection of inert gas nitrogen, 18 mol of toluene diisocyanate and 6 mol of trimethylolpropane and 2ml of catalyst solution at 60°C for 1.5h to obtain -NCO group-terminated prepolymer I, then add 6mol of stearyl alcohol, react at 70°C for 1h for branching reaction, and obtain two -NCO groups Grouped prepolymer II; mix 82mol of toluene diisocyanate, prepolymer II, and 36mol of polyether diol 1000 (dehydrated at 120°C for 2h before use),...

Embodiment 2

[0072] Comb Polyurethane Flame Retardant Water Repellent Finishing Agent Formula

[0073]

[0074] 1. Preparation

[0075] The raw materials in the above formula are prepared according to the preparation method of the present invention to prepare a comb-shaped polyurethane flame-retardant and water-repellent finishing agent. The specific preparation method is as follows: 1 part of dibutyltin dilaurate catalyst is diluted and dissolved with two parts of butanone, and after stirring evenly, a catalyst solution is obtained; under the protection of inert gas nitrogen, 18 mol of isophorone diisocyanate and 6 mol of trihydroxy Methylpropane and 2ml of catalyst solution were reacted at 60°C for 1.5h to obtain -NCO group-terminated prepolymer I, and then 6mol of stearyl alcohol was added and reacted at 70°C for 1h for branching reaction to obtain two -NCO group prepolymer II; mix 82mol of isophorone diisocyanate, prepolymer II, and 36mol of polyether diol 1000 (dehydrated at 120°C...

Embodiment 3

[0083] Comb Polyurethane Flame Retardant Water Repellent Finishing Agent Formula

[0084]

[0085] 1. Preparation

[0086] The raw materials in the above formula are prepared according to the preparation method of the present invention to prepare a comb-shaped polyurethane flame-retardant and water-repellent finishing agent. The specific preparation method is as follows: 1 part of dibutyltin dilaurate catalyst is diluted and dissolved with two parts of butanone, and after stirring evenly, a catalyst solution is obtained; under the protection of inert gas nitrogen, 18 mol of toluene diisocyanate and 6 mol of trimethylolpropane and 2ml of catalyst solution at 60°C for 1.5h to obtain -NCO group-terminated prepolymer I, then add 6mol of stearyl alcohol, react at 70°C for 1h for branching reaction, and obtain two -NCO groups group of prepolymer II; mix 82mol of isophorone diisocyanate, prepolymer II, and 36mol of polyether diol 1000 (dehydrated at 120°C for 2h before use), and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com