Process method for removing manganese from groundwater

A process method, groundwater technology, applied in chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc. The filter layer lacks theoretical guidance and the physiological characteristics are not completely clear, etc., to achieve the effect of good manganese removal, simple process and small investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

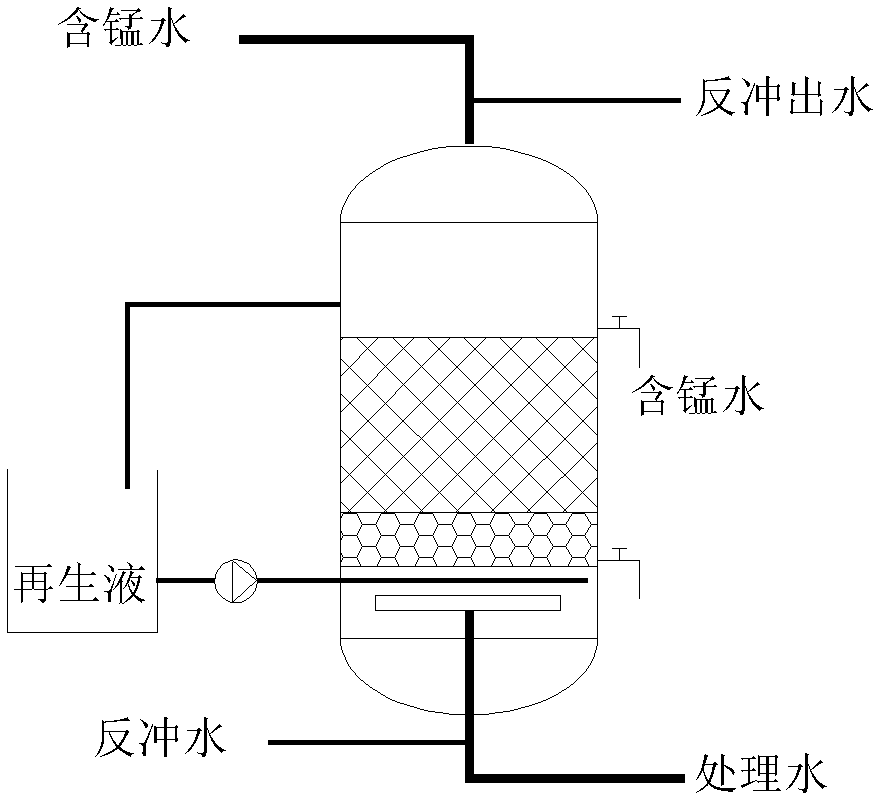

Method used

Image

Examples

Embodiment 1

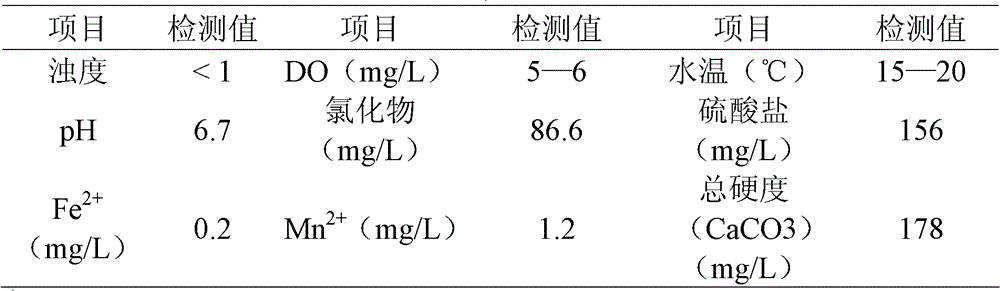

[0016] In this example, a certain manganese-containing well water in Jiaodong area is selected. The water quality is shown in Table 1. The manganese removal process of the present invention is used for manganese removal. The filter layer adopts a 1.2m composite filter layer, and the filtration rate is 6m / h. The effluent quality after treatment with the loaded filter material to remove manganese filter layer is as follows, pH=7.2, Mn 2+ =0.08mg / L. There is no maturity period, and instant use is realized.

[0017] Table 1 Raw water quality table

[0018]

Embodiment 2

[0020] In this example, a manganese-containing well water in Shandong area is selected. The water quality is shown in Table 2. The manganese removal process method of Example 1 is used for manganese removal, and the filtration rate is 10m / h. The manganese removal filter layer is loaded with a filter material. The quality of the treated effluent is as follows, pH=7.2, Mn 2+ =0.05mg / L.

[0021] Item

Embodiment 3

[0023] In this example, a manganese-containing well water in Shandong area is selected. The water quality is shown in Table 3; the filtration rate is 8m / h, and the effluent water quality after treatment with the loaded filter material to remove manganese filter layer is as follows, pH=7.2, Mn 2+ =0.08mg / L.

[0024] Item

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com