Method for producing boron-containing diammonium phosphate product

A diammonium phosphate and product technology, applied in the field of ammonium phosphate fertilizer production, to avoid serious impact, reduce water content, and improve production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

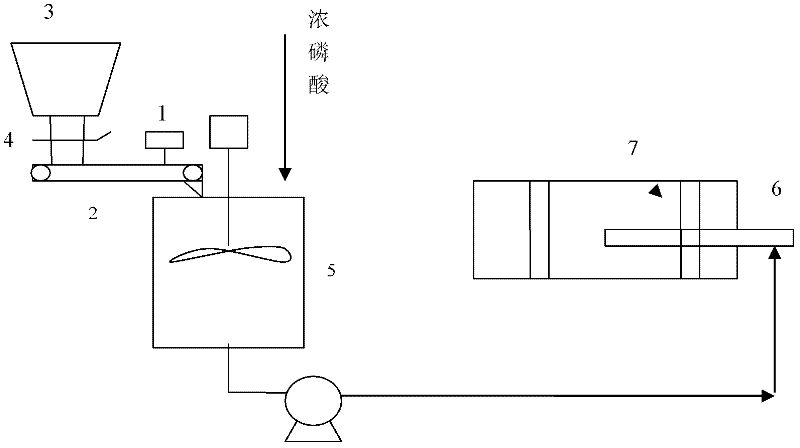

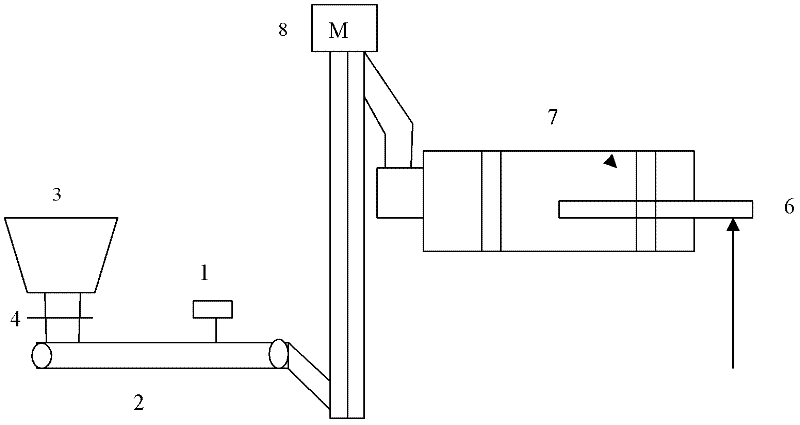

Method used

Image

Examples

Embodiment

[0024] Both series of diammonium phosphate plants of Wengfu (Group) Co., Ltd. adopt this process to produce boron-containing diammonium phosphate products. The addition method is as follows:

[0025] First, calculate the amount of borax that needs to be added based on the current hourly production quantity and the amount of sprayed grout. The specific calculation method is as follows:

[0026] 60m according to the series of shotcrete 3 / h is the standard, then the product quantity produced is G=60×1.25=75t / h, the boron content in the product is set at 0.75%, and the total boron content is X=0.75%×75t / h,

[0027] Let X be the total amount of boron contained in the product per hour, and the amount of borax that needs to be added is Y,

[0028] Then X = Y×(10.811×4 / 291.37)

[0029] Calculated from the above formula as follows:

[0030] Y=X / (10.811×4 / 291.37)=0.75%×G / (10.811×4 / 291.37)

[0031] =3.79T / H

[0032] In the formula: G is the output of a single series per hour;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com