Preparation method of dibenzoylmethane and application of dibenzoylmethane in molding processing of thermoplastic resin

A technology of dibenzoylmethane and methyl benzoate, applied in the field of preparation of beta-diketones, can solve the problems of high cost of raw materials, many by-products, low yield of dibenzoylmethane, etc., and achieves a condensation reaction cycle The effect of short, cost reduction, and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

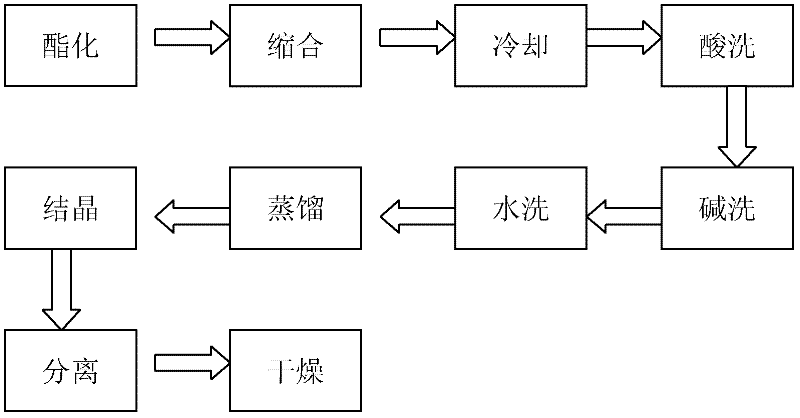

Method used

Image

Examples

Embodiment 1

[0083] Prepare dibenzoylmethane of the present invention according to the following steps

[0084] ①. Synthesis of methyl benzoate

[0085] Using benzoic acid and methanol as raw materials, using sulfuric acid as a catalyst, it is prepared by esterification and distillation

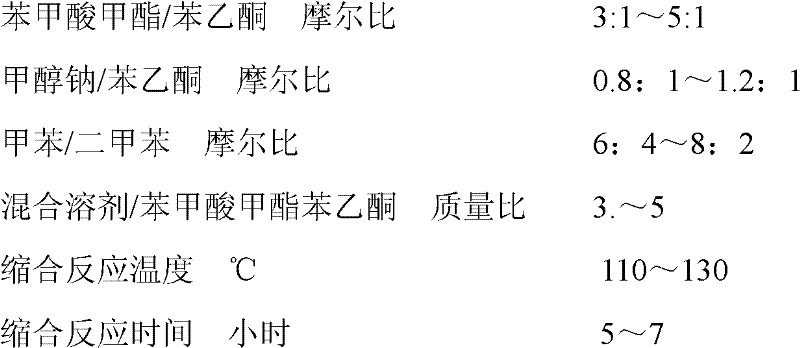

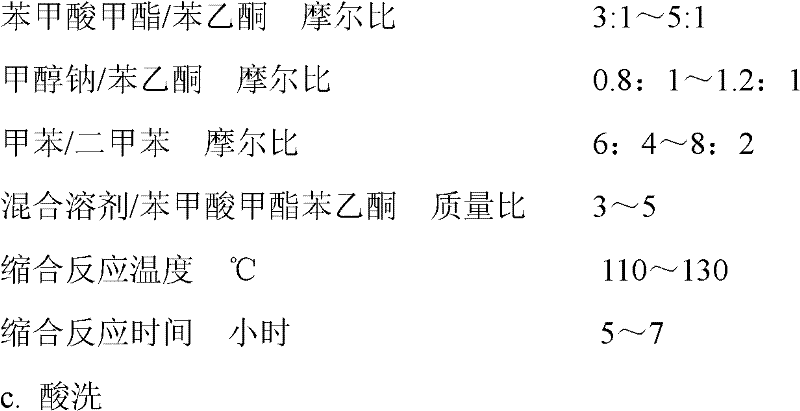

[0086] a. Esterification process conditions

[0087] Benzoic acid / methanol molar ratio 1:4~1:6

[0088] The esterification reaction temperature is 70~80°C

[0089] Response time hours 4~5

[0090] Put 366g of benzoic acid and 384g of methanol into a three-necked flask, raise the temperature to 70°C-80°C, after the benzoic acid is completely dissolved, add concentrated sulfuric acid dropwise, and reflux for 4-5 hours. After the reaction is completed, distill and recover the residual methanol to obtain the crude product.

[0091] b. Esterification solution treatment

[0092] The esterification liquid from step a is washed with water, alkali washed, and then washed with water until the pH of the washin...

Embodiment 2~ Embodiment 5

[0122] According to the method and step of Example 1, the stearoylbenzoylmethane product of the present invention is prepared according to the formula of Table 1

[0123] Table 1

[0124] Raw material and yield Example 2 Example 3 Example 4 Example 5 methyl benzoate 47.6 54.4 61.2 58 Acetophenone 12 12 12 12 toluene 125.16 139.44 204.96 245 Xylene 53.64 59.76 87.84 105 Sodium methoxide 15 15 15 15 Condensation yield% 85 86 84 85 Crystallization yield% 95 95 96 94

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com