Preparation method for high-performance room-temperature calcium-based composition phase-change energy storage material

A phase-change energy storage material and composition technology, applied in the field of materials, can solve the problems of expensive corrosion of potassium fluoride tetrahydrate, unsuitable energy storage materials, inconvenient preparation, etc., and achieve simple preparation methods, fewer types, and improved stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

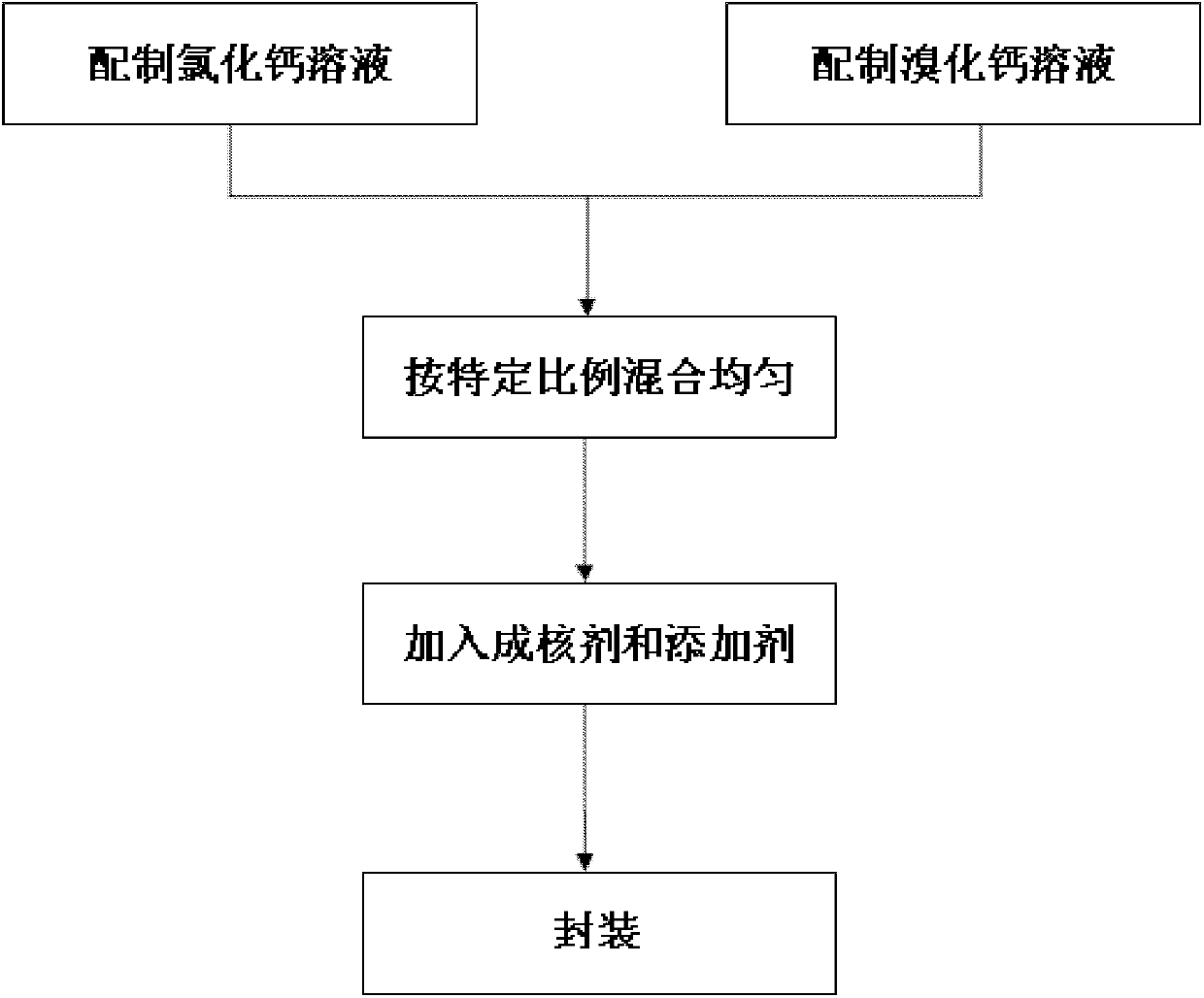

[0025] A preparation method of a high-performance room temperature calcium-based composition phase-change energy storage material, the steps are:

[0026] (1) Dissolve anhydrous calcium chloride or its hydrate and water in a molar ratio of 1:6 to make calcium chloride solution, and dissolve anhydrous calcium bromide or its hydrate and water in a molar ratio of 1:6 to make Calcium bromide solution;

[0027] (2) get the calcium chloride solution prepared in step (1) without adding calcium bromide solution, directly take out calcium chloride solution 20g;

[0028] (3) Add 0.4g SrCl to the sample in step (2) 2 ·6H 2 O, keep stirring to make it evenly mixed;

[0029] (4) Pour the brine compound obtained in step (3) into a container for packaging.

[0030] The test results of this implementation are shown in Table 1, and the phase transition temperature of this component is 28°C.

Embodiment 2

[0032] (1) Dissolve anhydrous calcium chloride or its hydrate and water in a molar ratio of 1:6 to make calcium chloride solution, and dissolve anhydrous calcium bromide or its hydrate and water in a molar ratio of 1:6 to make Calcium bromide solution;

[0033] (2) get the calcium chloride solution prepared in step (1) and add calcium bromide solution, be mixed with 20g of saline compound containing 10% calcium bromide solution;

[0034] (3) Add functional additives 0.4g KBr and 0.2g KCl respectively to the sample in step (2) to make its performance more stable, add nucleating agent 0.2g SrCl 2 ·6H 2 O and 0.2g Ba(OH) 2 ·8H 2 O, keep stirring to make it evenly mixed;

[0035] (4) Pour the brine compound obtained in step (3) into a container for packaging.

[0036] The test results of this implementation are shown in Table 1, and the phase transition temperature of this component is 24°C.

Embodiment 3

[0038] (1) Dissolve anhydrous calcium chloride or its hydrate and water in a molar ratio of 1:6 to make calcium chloride solution, and dissolve anhydrous calcium bromide or its hydrate and water in a molar ratio of 1:6 to make Calcium bromide solution;

[0039] (2) get the calcium chloride solution prepared in step (1) and add calcium bromide solution, be mixed with 20g of saline compound containing 20% calcium bromide solution;

[0040] (3) Add functional additives 0.4g KBr and 0.2g KCl respectively to the sample in step (2) to make its performance more stable, add nucleating agent 0.2g SrCl 2 ·6H 2 O and 0.2g Ba(OH) 2 ·8H 2 O, keep stirring to make it evenly mixed;

[0041] (4) Pour the brine compound obtained in step (3) into a container for packaging.

[0042] The test results of this implementation are shown in Table 1, and the phase transition temperature of this component is 20°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com