Automatic rapping dust removing system

A rapping and ash removal, automatic technology, applied in the direction of granular/powder fuel gasification, etc., can solve the problems of poor rapping effect, thickening of ash on the surface of the electrode plate, and reduced dust collection efficiency, so as to increase the energy transfer efficiency. , reduce friction damage, reduce friction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

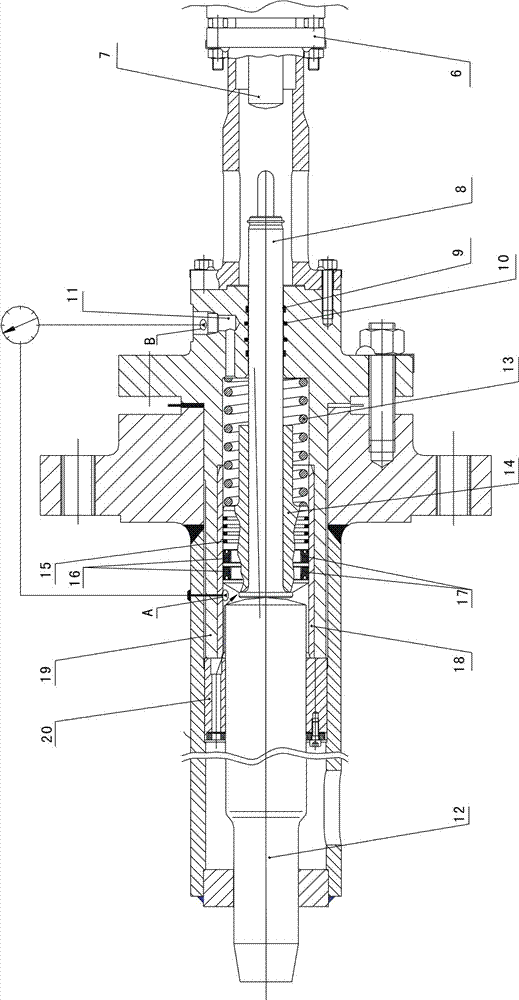

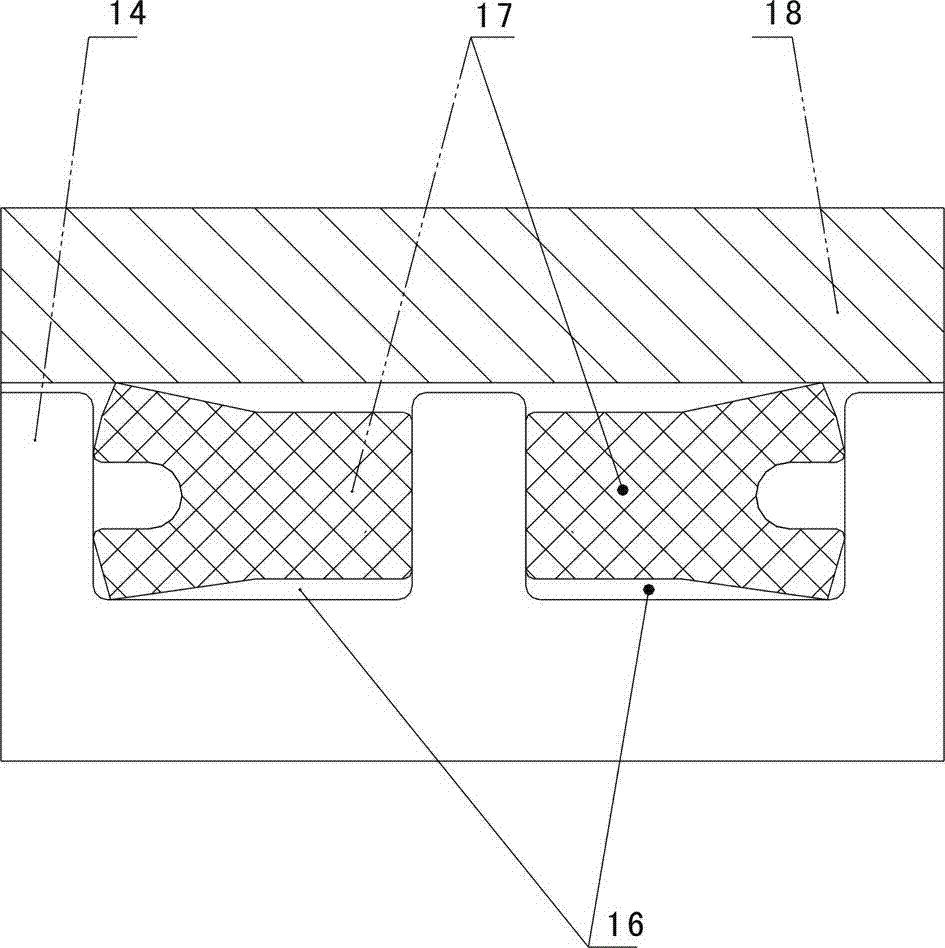

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

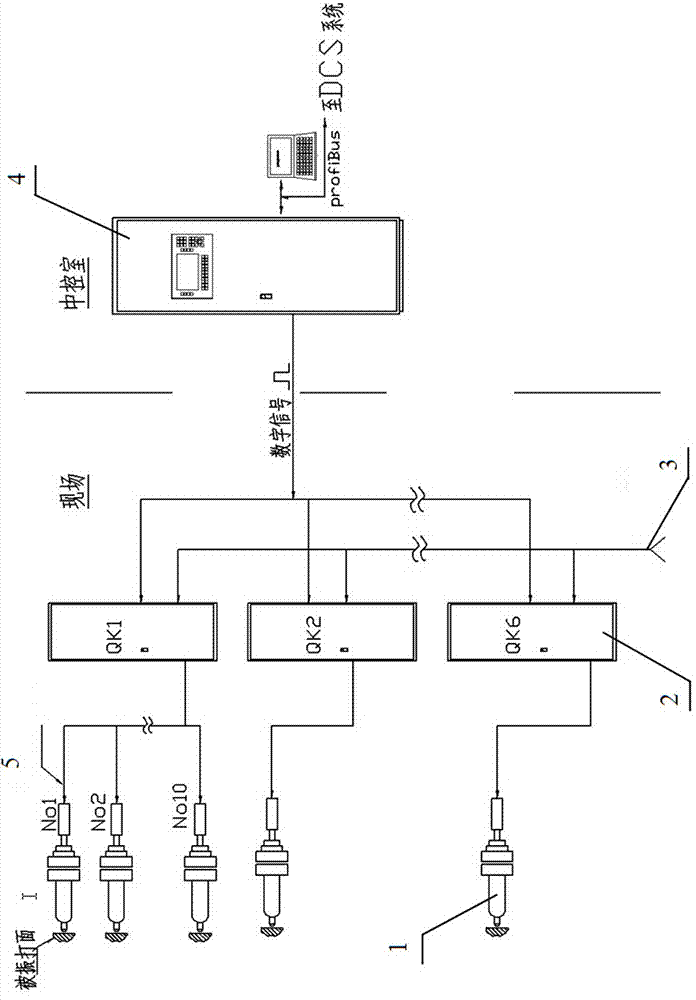

[0034] Such as figure 1, an automatic rapping ash removal system, including a mechanical rapper 1, a gas source 3, a gas leakage alarm device 5, an electrical control cabinet 2 and a PLC programmable control cabinet 4, the PLC programmable control cabinet The cabinet is connected to the DCS system and connected to the electrical control cabinet. The electrical control cabinet is connected to the cylinder on the mechanical vibrator through the gas pipe. Multiple mechanical vibrators are installed on different parts of the water wall of the gasifier to realize automatic vibration. Ash removal, gas leakage alarm device is connected with the mechanical vibrator, nitrogen is passed into the air inlet of the mechanical vibrator through the sealed nitrogen hose; the compressed air is connected to the electrical control cabinet and is set to be a power source of 0.35...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com