Method for recovering NdFeB waste material by cold crucible induction smelting technology

An induction smelting and vacuum induction smelting technology is applied in the field of recycling NdFeB waste, which can solve the problems of serious pollution, complex process and high cost, and achieve the effects of small investment in plant construction, simple process and low production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

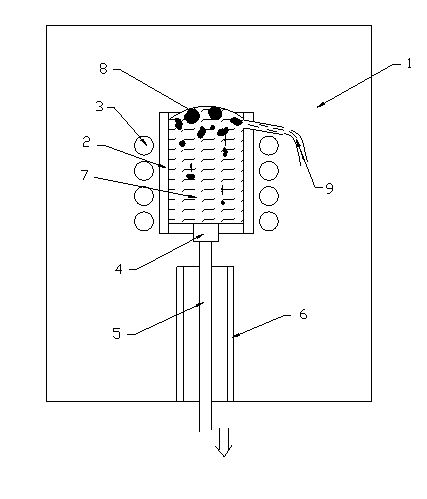

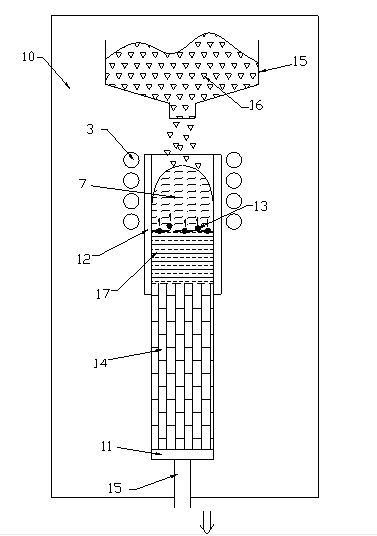

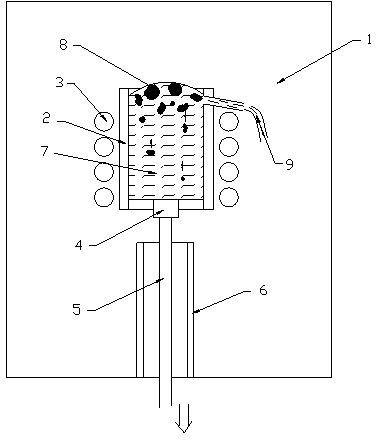

[0032] see Figure 1 to Figure 2 , the present invention proposes a kind of method that reclaims NdFeB waste material with cold crucible induction smelting technology, takes recycling and processing NdFeB waste material 1500 tons / year as example, this recovery method comprises the following steps:

[0033] Step 1: Pre-treatment process: first manually sort out the obvious foreign matter in the NdFeB waste, then use kerosene to clean the oil on the surface of the waste, and then crush the waste into particles with a particle size of less than 3mm, and select non-ferrous materials in a magnetic separator. Magnetic debris, and finally dry the magnetically separated materials;

[0034] Step 2: Rough purification process: such as figure 1 As shown, NdFeB waste is heated in cold crucible vacuum induction smelting equipment 1, and after melting, the power is increased to make the feed liquid 7 churn to remove volatile impurities, and then the power is reduced to make the impurity sl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com