Reserving agent for washing jean garments and preparation method thereof

A technology of anti-dyeing agent and clothing, which is applied in the field of washing anti-dyeing agent, can solve the problems of protein inactivation, reduce anti-dyeing effect of anti-dyeing agent, destroy protein structure, etc., and achieve simple production process, good production prospect and market application Prospect, excellent effect of anti-backstaining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The preparation method of a kind of anti -dye -washing agent of denim clothing is as follows:

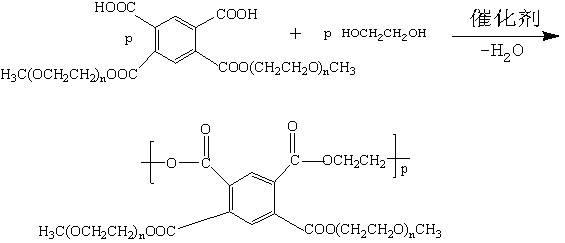

[0044] (1) Preparation of polyether dual carboxylic acid A1:

[0045] In the reactor with a temperature of 80 ° C, add 2L of 2L, and the average phenyl acid anhydride 2.18kg and the average molecular weight of a polyethylene monotolin 10kg are added to the reactor.The constant temperature reaction is then for 6 hours under 100 ° C, and polyether dilateral carboxylic acid A1 is made.

[0046] (2) Preparation of anti -dye C1:

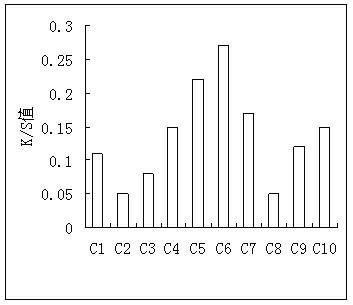

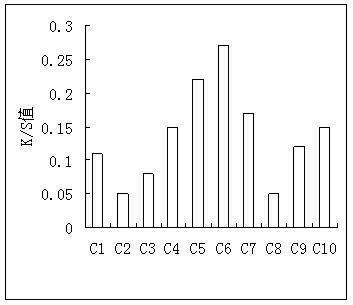

[0047] Polyether dilateral carboxylic acid A1 12.18kg, ethylene glycol 62g, sulfate di ethyl 1.3g of esterization reactions, the constant temperature reaction at 100 ° C for 60 minutes, and then heated to the esterization response at 180 ° C.When it reaches 17.5g, the reaction is over.Then perform decompression and distillation at this temperature for 1 hour, and the dyshane is completely removed from the reactor to obtain the anti -infected agent C1, that i...

Embodiment 2

[0050] The preparation method of a kind of anti -dye -washing agent of denim clothing is as follows:

[0051] (1) Preparation of polyether dual carboxylic acid A2:

[0052] In the reactor with a temperature of 85 ° C, adding 2.5L of dyshane is added, and the average phenyl acid anhydride 2.18kg and the average molecular weight of the average molecular weight of 1000 are added to the reactor with 20kg, and the mixing is mixed evenly.The constant temperature reaction is then for 5.5 hours under 100 ° C, and polyether dilateral carboxylic acid A2 is made.

[0053] (2) Preparation of anti -dye C2:

[0054] Polyettic dilateral carboxylic acid A2 22.18kg, ethylene glycol 62g, a esterization reaction to toluene sulfonic acid 2.3g, 50 minutes of constant temperature reaction at 100 ° C, and then increased to the esterization response at 170 ° C.Reaching 17.2g, the reaction is over.Then reducing decompression and distillation at this temperature for 2.5 hours, and the dyshane was completel...

Embodiment 3

[0057] The preparation method of a kind of anti -dye -washing agent of denim clothing is as follows:

[0058] (1) Preparation of polyether dual carboxylic acid A3:

[0059] In the reactor with a temperature of 90 ° C, add 2 methane 3L, and the average phenyl acid anhydride 2.18kg and the average molecular weight of a polyethylene glycol monoethyl ether 40kg are added to the reactor.The constant temperature reaction was then made at 100 ° C for 3.5 hours, and the polyether dilateral carboxylic acid A3 was made.

[0060] (2) Preparation of anti -dye C3:

[0061]Polyettic dilateral carboxylic acid A3 42.18kg, ethylene glycol 62g, and 5.0g of hydrochloric acid permeate the esterization reaction. The constant temperature reaction is 40 minutes under 100 ° C conditions, and then the esterization reaction is 2.5 hours at the condition of the temperature at 160 ° C., The reaction is over.Then reducing decompression and distillation at this temperature for 2.5 hours, and the dyshane was co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com