Wood chip extrusion method and equipment for chemimechanical pulping

A technology of chemical mechanical and extrusion methods, applied in the field of chemical mechanical pulping, which can solve the problems of uneven extrusion, large hardness differences, and poor uniformity of wood chips, so as to reduce ineffective consumption, stable operation, and good extrusion effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

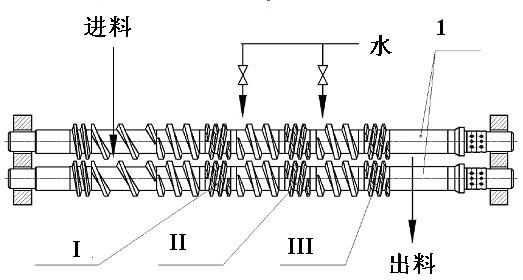

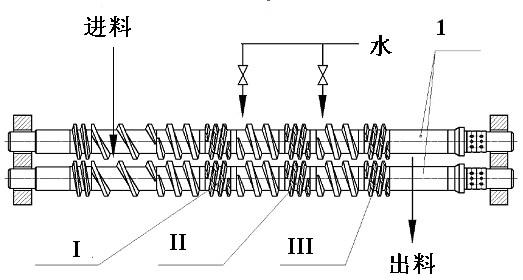

[0029] Commercial eucalyptus wood chips are first screened to remove oversized wood chips and wood chips; the screened wood chips are washed to remove heavy impurities such as metal and sediment; after washing, the wood chips are soaked for 10 hours to remove free water in the wood chips, and then heated at 100~105 °C Pre-steaming under normal pressure for 15 minutes, so that the raw material lignin is initially softened, and the damage to the fiber caused by screw extrusion is reduced; the steamed wood chips are then respectively set in the axial direction with a compression ratio of 2.8:1, 4 : 1, 6: 1 (volume ratio), extruded by a non-cantilever twin-screw extruder with 3 press zones, so that the wood chips are subjected to gradually increasing extrusion along the spiral axis, and the two press zones are equipped with The water washing device washes the extruded wood chips, and the extruded wood chips are sent to the impregnator for chemical pretreatment. After extrusion, th...

Embodiment 2

[0031] Commercial Chinese fir chips are first screened to remove oversized wood chips and sawdust; the screened wood chips are washed with water to remove heavy impurities such as metal and sediment; after washing, the wood chips are soaked for 12 hours, dehydrated to remove free water in the wood chips, and then heated at 100~105oC Pre-steaming under normal pressure for 20 minutes, so that the raw material lignin is initially softened, and the damage to the fiber caused by screw extrusion is reduced; the steamed wood chips are then respectively set in the axial direction with a compression ratio of 2.8:1, 4 : 1, 6: 1 (volume ratio), extruded by a non-cantilever twin-screw extruder with 3 press zones, so that the wood chips are subjected to gradually increasing extrusion along the spiral axis, and the two press zones are equipped with The water washing device washes the extruded wood chips, and the extruded wood chips are sent to the impregnator for chemical pretreatment. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com