Time-sharing power supply control system for liquid helium level gauge

A technology of power supply control and control system, which is applied in the direction of electrical program control, liquid level indicator for physical variable measurement, program control in sequence/logic controller, etc. Loss and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

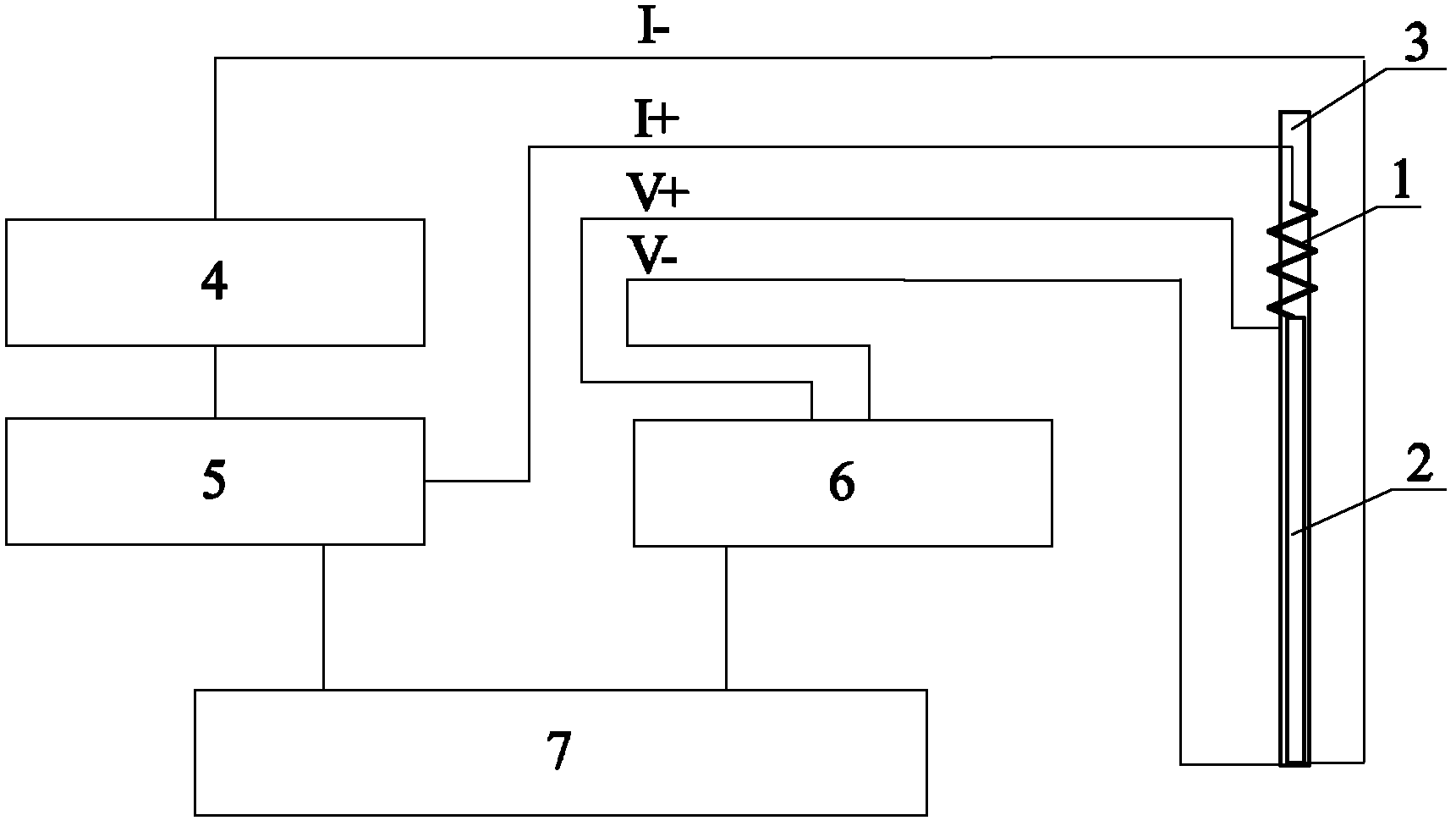

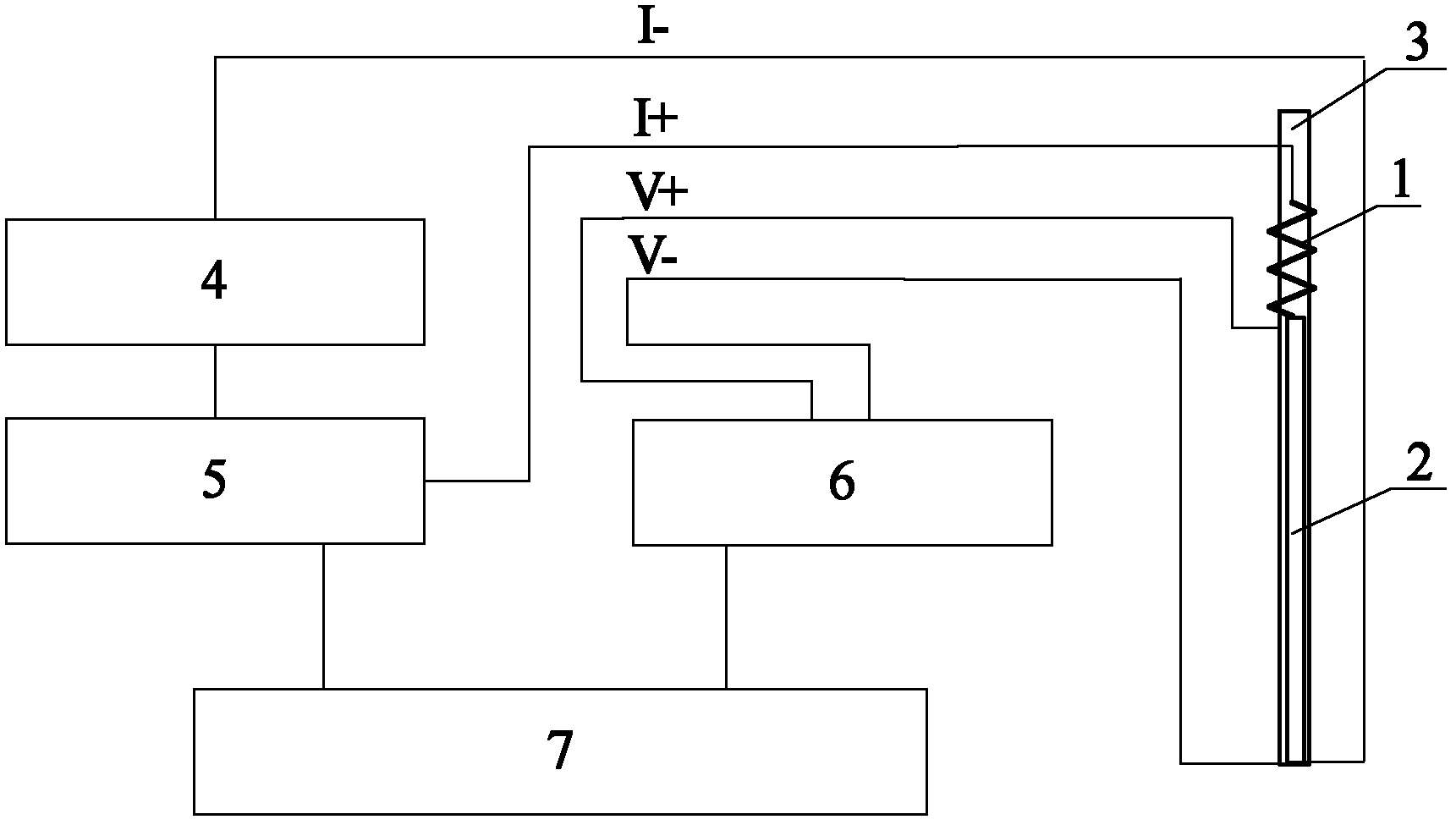

[0013] Such as figure 1 As shown, the device of the present invention includes a liquid helium level gauge, a constant current source 4 and a computer control system 7 . The liquid helium level gauge includes a heating wire 1, a niobium-titanium superconducting wire 2 and a liquid level gauge fixing rod 3, and the heating wire 1 and the niobium-titanium superconducting wire 2 are welded in series and fixed to the measuring rod 3 of the liquid level gauge. The diameter of the niobium-titanium superconducting wire 2 is 59 microns, and the resistance of the heating wire 1 is 20 ohms. When working, install the liquid helium level gauge vertically in the liquid helium Dewar, which is filled with liquid helium, and the voltage lead wire and current lead wire of the liquid helium level gauge are drawn out from the upper end of the liquid level gauge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com