Method of adhering flexible thin-film material to glass substrate

A flexible film material, glass substrate technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., to achieve the effects of good specificity, high yield and high viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

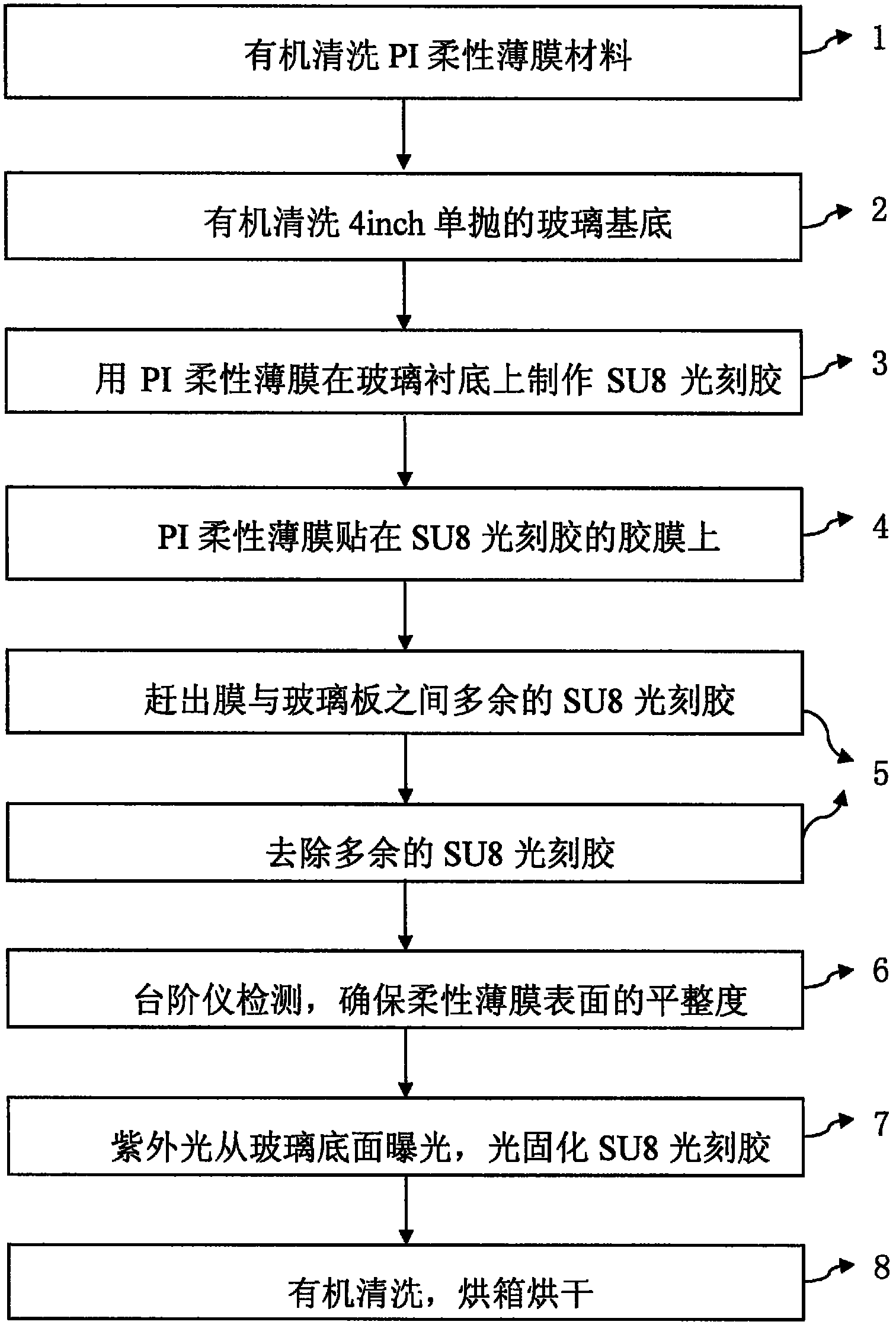

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

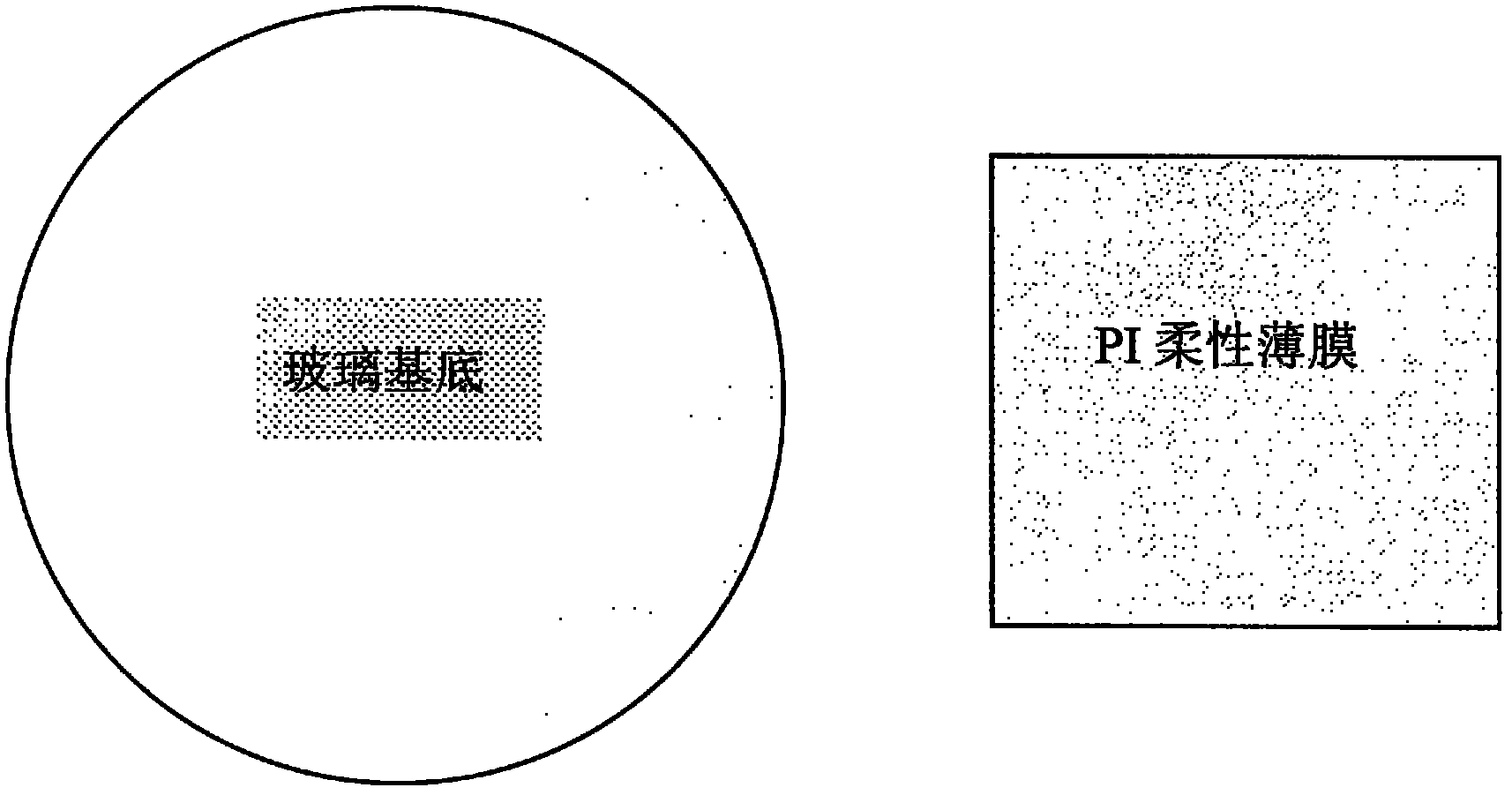

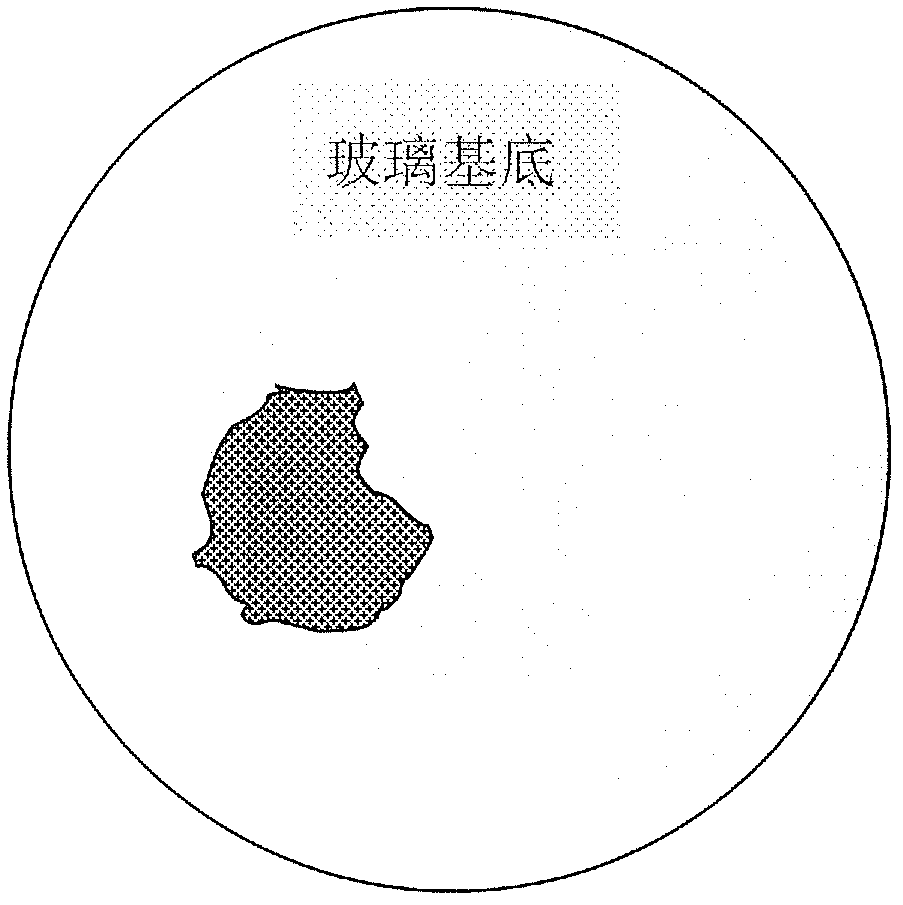

[0032] Transferring the existing semiconductor process on inorganic materials to flexible film materials such as PI and PET is a shortcut to realize lightweight and flexible devices. Inorganic micro-nano processing technology has high requirements on the flatness of the substrate surface. Flexible thin film materials are soft and have poor surface flatness, making it difficult to directly fabricate devices on flexible thin film materials. The invention can not only realize the lightweight, bendable, and low-cost of inorganic devices, but also utilize the existing mature microelectronic technology to effectively compensate for the shortcomings of some organic processes, such as difficulty in organic processes and poor chara...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com