Method for preparing perfluorohexane surfactant serving as main agent of aqueous film-forming extinguishing agent directly

A foam fire extinguishing agent and surfactant technology, applied in the field of surfactant preparation, can solve the problems of serious environmental pollution, complex process and high cost, and achieve the effects of simple equipment requirements, easy availability of raw materials and short fire control time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

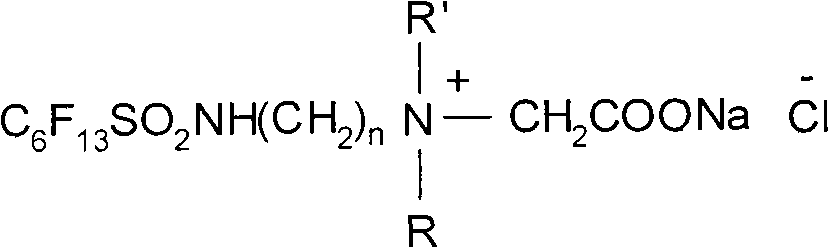

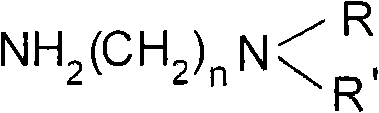

Method used

Image

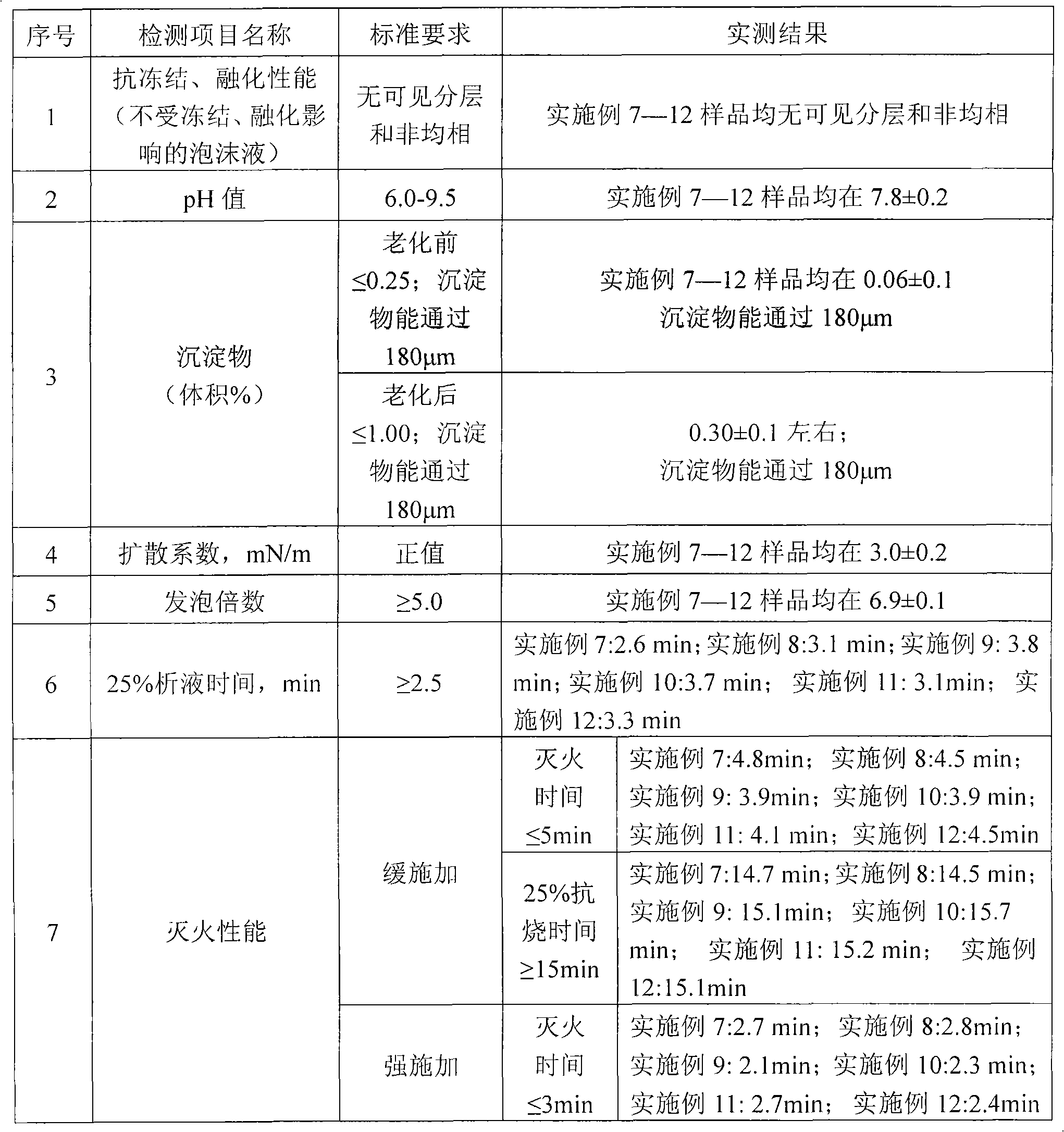

Examples

Embodiment 1

[0021] Add 3.0 moles of perfluorohexanesulfonyl fluoride and 0.006 moles of aluminum isopropoxide into a 20-liter reaction kettle equipped with a condensing reflux device, and add 3.6 moles of N,N-dimethylpropane in batches under stirring. amine, and slowly increase the temperature, the system temperature does not exceed 70 ℃. After the dropwise addition, react at about 80°C for 2 hours, and cool to room temperature, in which a small amount of hydrogen fluoride gas is introduced into the lye pool from the upper port of the condenser tube for absorption.

[0022] Add the pre-prepared 3.6 mol concentration of 20% sodium chloroacetate aqueous solution into the above system of the reaction kettle, and add water to 10 L, and reflux for 1 hour to obtain a brownish-yellow liquid. Cool to room temperature, wherein a small amount of quaternary ammonium salt by-products are also good surfactants, and the resulting material does not need to be separated, and is designated as sample 1, wh...

Embodiment 2

[0024] As in Example 1, in the ammonolysis reaction, the amount of N,N-dimethylpropylenediamine was 3.9 moles, and the reaction temperature was 100° C., and the reaction was carried out for 3 hours; during the quaternization reaction, the amount of sodium chloroacetate also rose to 3.9 moles, Prepare an aqueous solution with a concentration of 20%, reflux for 2 hours, and designate it as sample 2, and set it aside for use.

Embodiment 3

[0026] As in Example 1, in the ammonolysis reaction, 0.009 moles of aluminum isopropoxide, 3.9 moles of N,N-dimethylpropylenediamine, and a reaction temperature of 110°C for 3 hours; during the quaternization reaction, sodium chloroacetate The dosage is 3.9 mol, and the concentration is 30% aqueous solution, and the reaction is refluxed for 1 hour, which is designated as sample 3 and is ready for use.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com