Method and device for purifying high-temperature smoke containing persistent organic pollutants

A technology for organic pollutants and high-temperature flue gas, which is applied in the field of flue gas purification and treatment, can solve the problems of secondary pollution, high construction cost, and high operating cost, and achieves the effect of reducing operating cost, removing completely, and reducing water consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

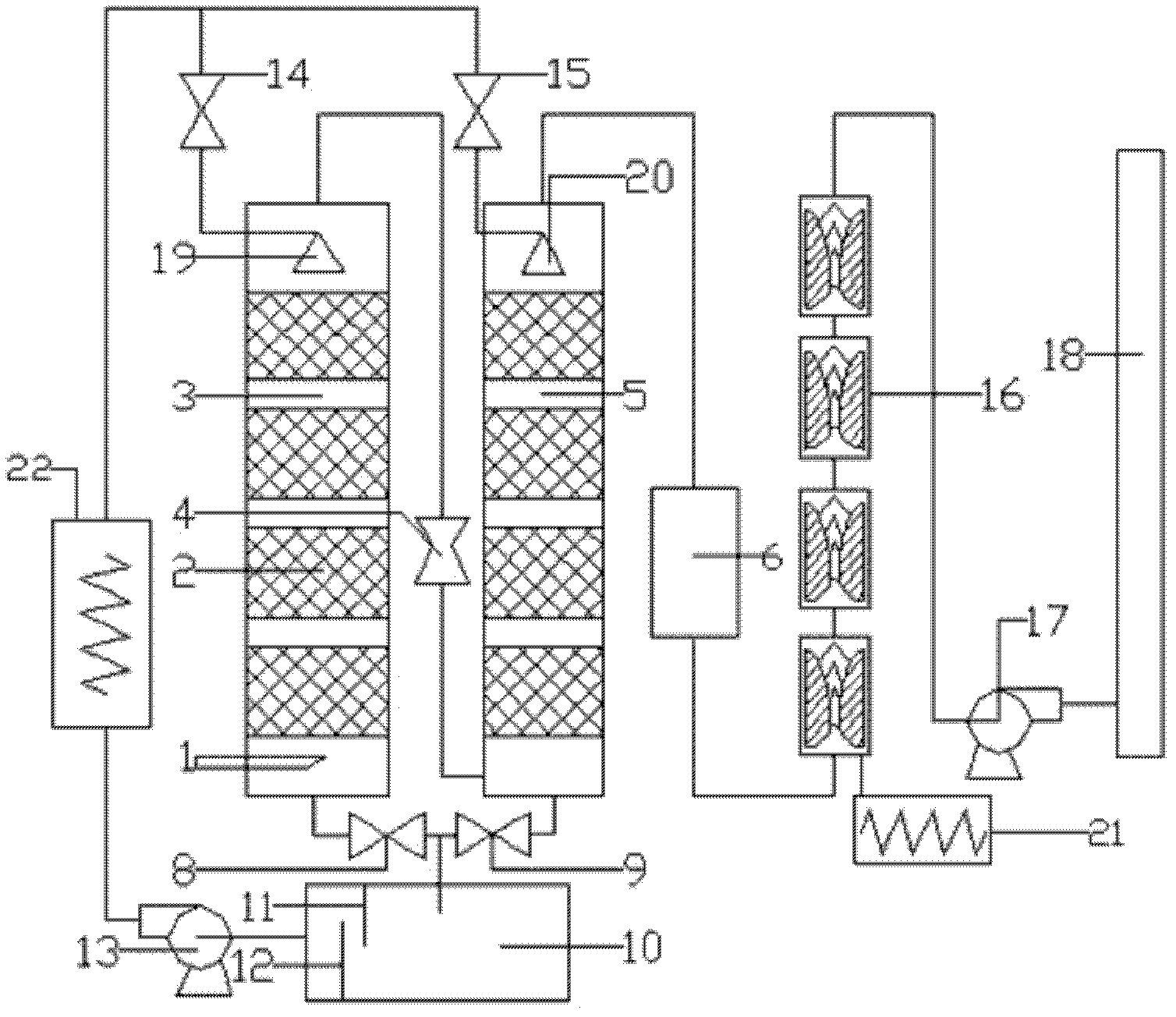

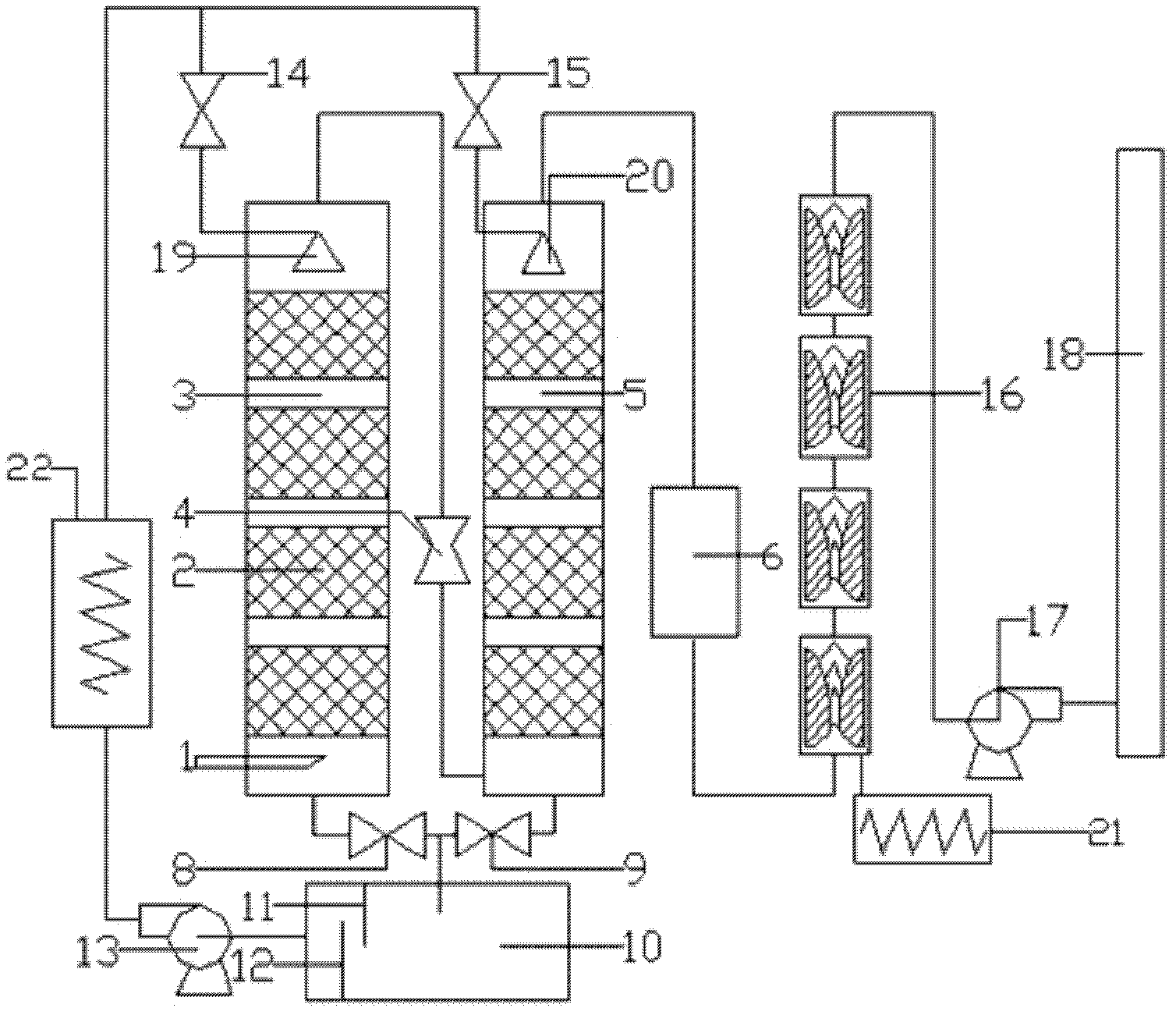

[0026] Embodiment: purifying polychlorinated biphenyls (PCBs) in high-temperature flue gas

[0027] PCBs-containing high-temperature smoke is produced by heating polychlorinated biphenyls (PCBs)-contaminated soil. Flue gas flow rate is 6m 3 / h, the flue gas temperature is 500°C, and the initial PCBs content in the flue gas is 44.5mg / m 3 .

[0028] The gas purification process is as follows: open valve 8, valve 9, valve 14, and valve 15, open induced draft fan 17, open high-voltage power supply 21, and open circulating water pump 13. The high-temperature flue gas containing PCB enters the primary spray tower 3 through the inlet 1, and the flue gas flow rate is 6m 3 / h, directly mixed with the spray water at the packing layer 2, the inner diameter of the primary spray tower 3 is 108mm, the liquid flow rate of the primary spray tower is 40L / h, the persistent organic pollutants in the exhaust gas are condensed, and the gas After passing through the first-stage spray tower 3, it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com