Pneumatic transmission and blast furnace injection technology and system for removing dust of coke oven

A coke oven dedusting and pneumatic conveying technology, which is applied to blast furnaces, conveyors, blast furnace details, etc., can solve problems such as affecting the air permeability of the sintered material layer, easy to raise dust, fall, and poor air permeability of the sintered material layer, etc., to achieve The concept of production and management, the effect of reducing the labor intensity of employees

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

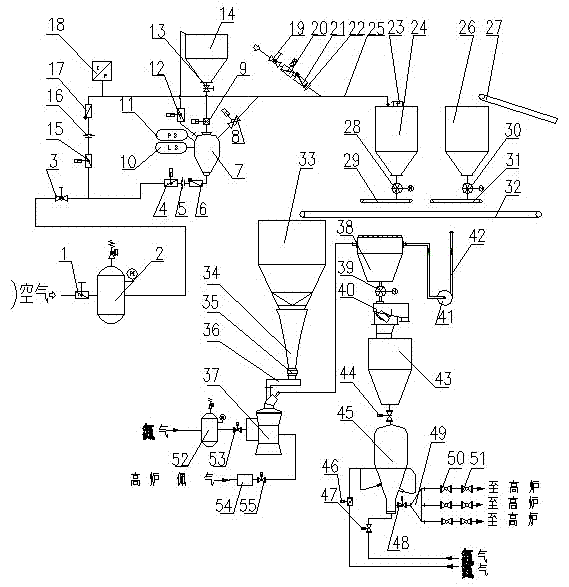

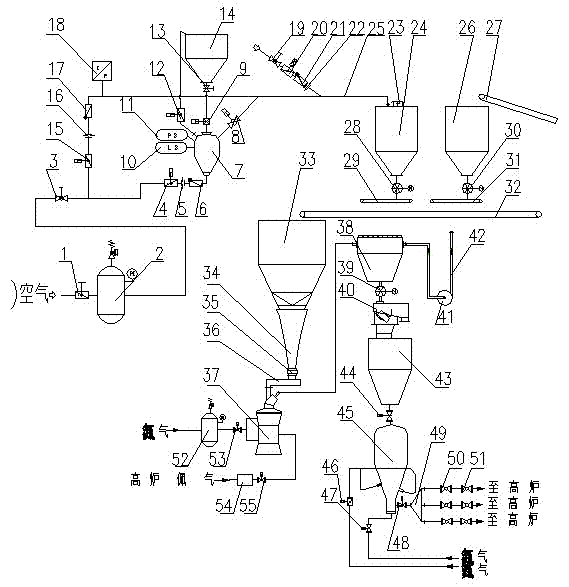

[0020] Below in conjunction with process schematic diagram and system, the process of the present invention is described in detail:

[0021] (1) Balance the air pressure between the coke oven dedusting ash storage bin and the ash delivery bin pump: open the pneumatic valve 12 to balance the air pressure between the coke oven dedusting ash storage bin 14 and the ash delivery bin pump 7; the purpose of this operation is Ensure that the coke oven dedusting ash in the coke oven dedusting ash storage bin 14 can smoothly enter the ash delivery bin pump 7 .

[0022] (2) The coke oven dust in the coke oven dust storage bin enters the ash delivery bin pump: open the pneumatic valve 9, and the ash delivery bin pump 7 starts to feed, that is, the coke oven dust removal ash in the coke oven dust removal storage bin 14 Enter the ash bin pump 7, when the material level reaches the set value of the material level gauge 10, the pneumatic valve 9 is closed, and the feeding operation of the ash...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com