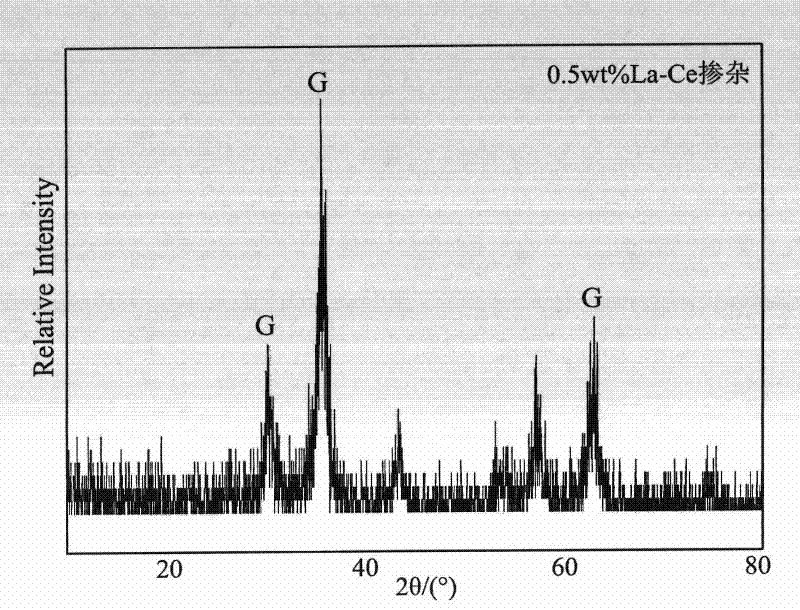

Preparation method of La-Ce (rhodium-cerium) codoped gama-Fe2O3 nanomaterial

A co-doping and nano-technology, which is applied in the preparation of La-Ce co-doped nano-γ-Fe2O3 materials and the field of Fe2O3 materials, can solve the problems of no prior art disclosure and achieve good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

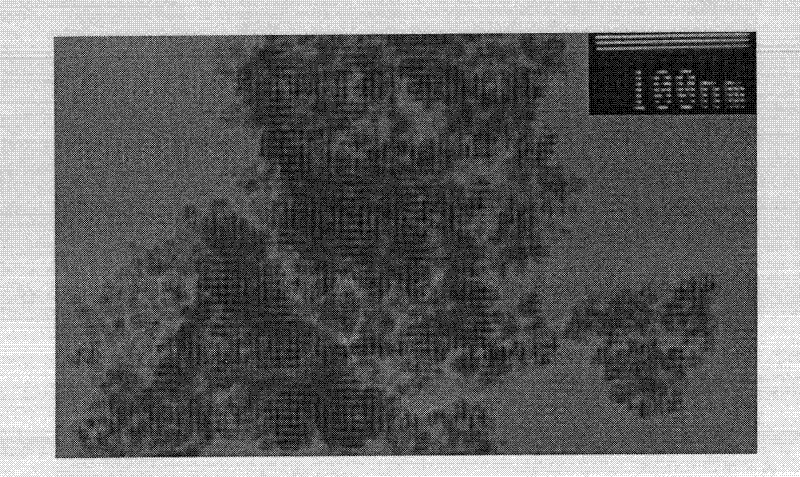

[0022] Embodiment 1: A kind of La-Ce co-doped nano-γ-Fe 2 o 3 The preparation method of material, this preparation method comprises the steps:

[0023] Weigh a certain amount of Fe(NO 3 ) 3 9H 2 O was dissolved in distilled water to prepare 10wt% ferric nitrate solution, and 175ml of it was poured into a 500ml beaker. Take La(NO 3 ) 3 and Ce(NO 3 ) 3 Add it directly into the beaker containing ferric nitrate solution and stir for 30 minutes. Under the condition of continuous stirring, slowly add 27.9g of dispersant octylphenol polyoxyethylene ether to make aqueous solution A; prepare 27.6g of complexing agent citric acid into 0.5mol / L aqueous solution B.

[0024] Heat solution A to 70°C and keep the temperature constant, stir at constant temperature for 30 minutes, and then add solution B dropwise (15 drops / min). After the dropwise addition was completed, the constant temperature stirring was continued for 24 h to obtain a thick gel. Dry the gel at 100°C for 10 hours...

Embodiment 2

[0030] Except that the calcination temperature was increased to 600°C, other conditions were the same as in Example 1, and the obtained γ-Fe 2 o 3 The average particle diameter is 12.2 nm.

Embodiment 3

[0038] Take La(NO 3 ) 3 and Ce(NO 3 ) 3 Except directly adding in the beaker that ferric nitrate solution is filled and stirring, all the other conditions are the same as in Example 1, and the obtained γ-Fe 2 o 3 The average particle diameter is 16.4 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com