Gas-liquid blending and stirring device of sewage-sludge complete mixing type anaerobic fermentation tank and treatment method thereof

An anaerobic fermentation tank and gas-liquid mixing technology, applied in the field of fermentation systems, can solve the problems of inability to achieve complete mixing, small disturbance range of stirring intensity, large sub-retention area, etc., and achieve significant economic and social benefits, Reduce engineering investment and improve the effect of mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

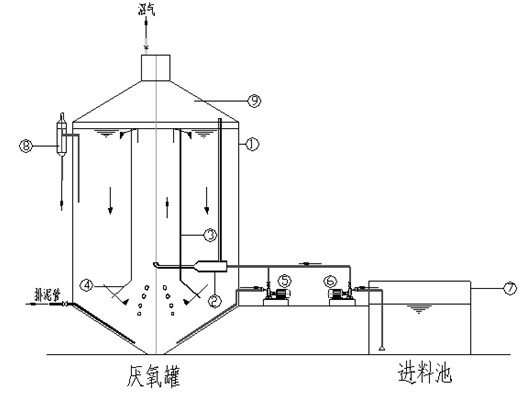

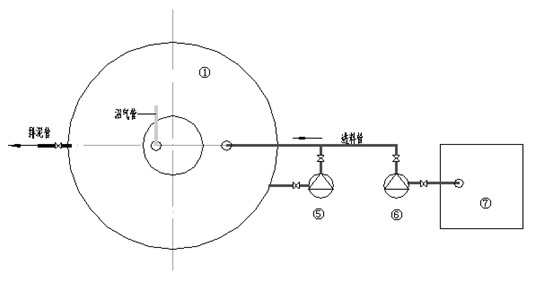

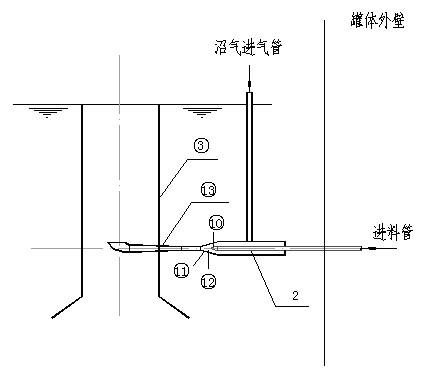

[0032] Accompanying drawing is embodiment of the present invention.

[0033] Below in conjunction with accompanying drawing, content of the invention will be further described:

[0034] refer to figure 1 , figure 2 As shown, a gas-liquid mixing system device of a sewage sludge full-mix anaerobic fermentation tank includes an anaerobic fermentation tank, a gas-liquid mixing device, a gas lifting diversion device, a gas collection diversion horn, a circulating stirring pump, and a raw liquid Feeding pump, feed tank, safety valve, trapezoidal tank cover, inverted triangle tank bottom, biogas pipe, the upper end of the anaerobic fermentation tank 1 is connected to the trapezoidal tank cover 9, and the lower end is connected to the inverted triangle tank bottom. The upper left side of the tank 1 is connected to the safety valve 8 through a pipeline. The center of the inner cavity of the anaerobic fermentation tank 1 is connected to a gas lift diversion device 3, and the lower en...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com