Healant for wetted surface

A repairing agent, wet surface technology, applied in the field of epoxy modified two-component reactive wet surface adhesive, can solve the problems of difficult to achieve strength and temperature resistance, large foreign exchange consumption, unsatisfactory performance, etc., and reach the operating temperature range. Wide, fast repair speed, high bonding strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

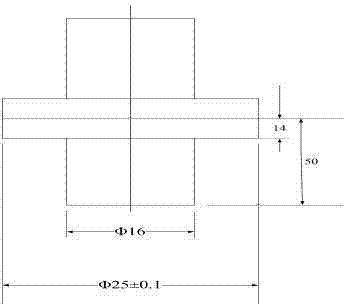

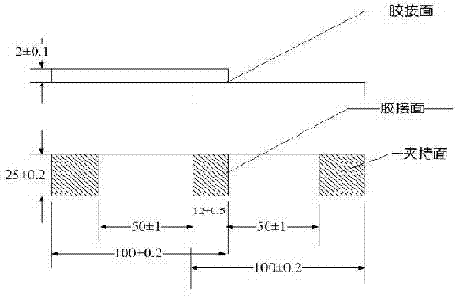

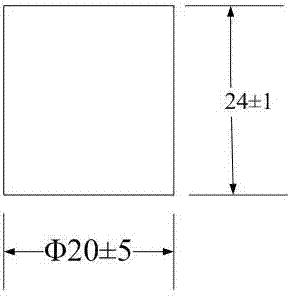

Image

Examples

Embodiment 1-3

[0060] A component is epoxy resin E44 7500g, epoxy resin E51 1500g, aluminum oxide 143g, stainless steel powder 440g, cement 4000g, glass fiber 1000g and white carbon black 70g; B component is KH550 silane coupling agent 43g, DMP -30 (2,4,6-tris(dimethylaminomethyl)phenol) 650g, low-molecular polyamide 650 860g and white carbon black 800g; the above-mentioned components A and B are in a weight ratio of 5:1~ Weigh in a ratio of 6:1 and mix well. The concrete proportioning ratio of each embodiment is shown in Table 1.

[0061] Table 1

[0062] Example 1 2 3 Grade TG620 TG621 TG622 A, B ratio 5:1 5.3:1 6:1

[0063] The seven performance indicators of tensile strength, tensile shear strength, compressive strength, hardness, wet surface resistance, corrosion resistance and temperature resistance were tested according to the Ministry of Chemical Industry and national standards. The test methods and test results are as follows:

[0064] 3.1 Tens...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com