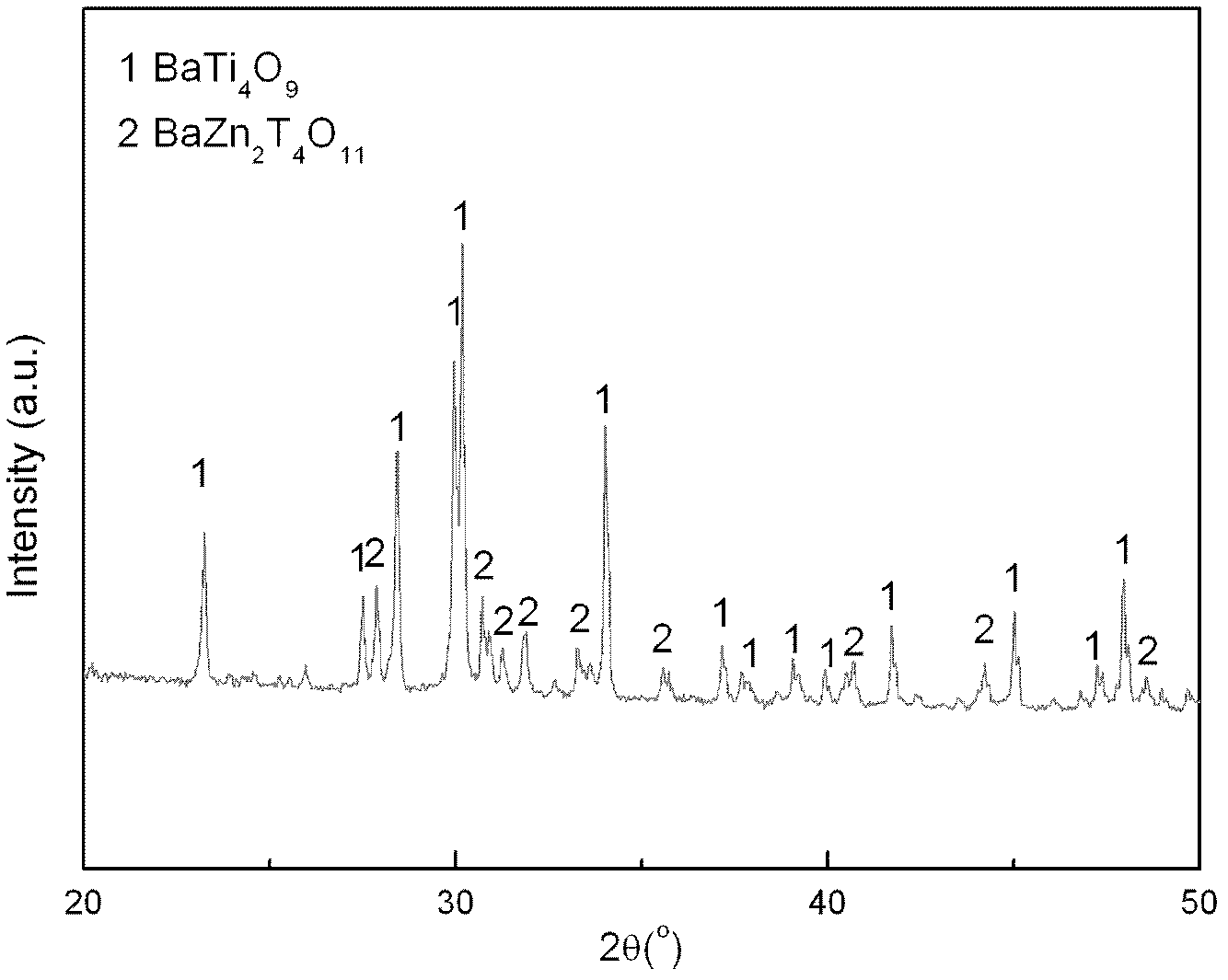

Compound BZT microwave ceramic dielectric material and preparation method thereof

A technology of dielectric materials and microwave ceramics, which is applied in the field of composite BZT microwave ceramic dielectric materials and its preparation, can solve the problems of high sintering temperature, unfavorable wide application, and hindrance of large-scale practical application, and achieve the effect of easy stable production and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

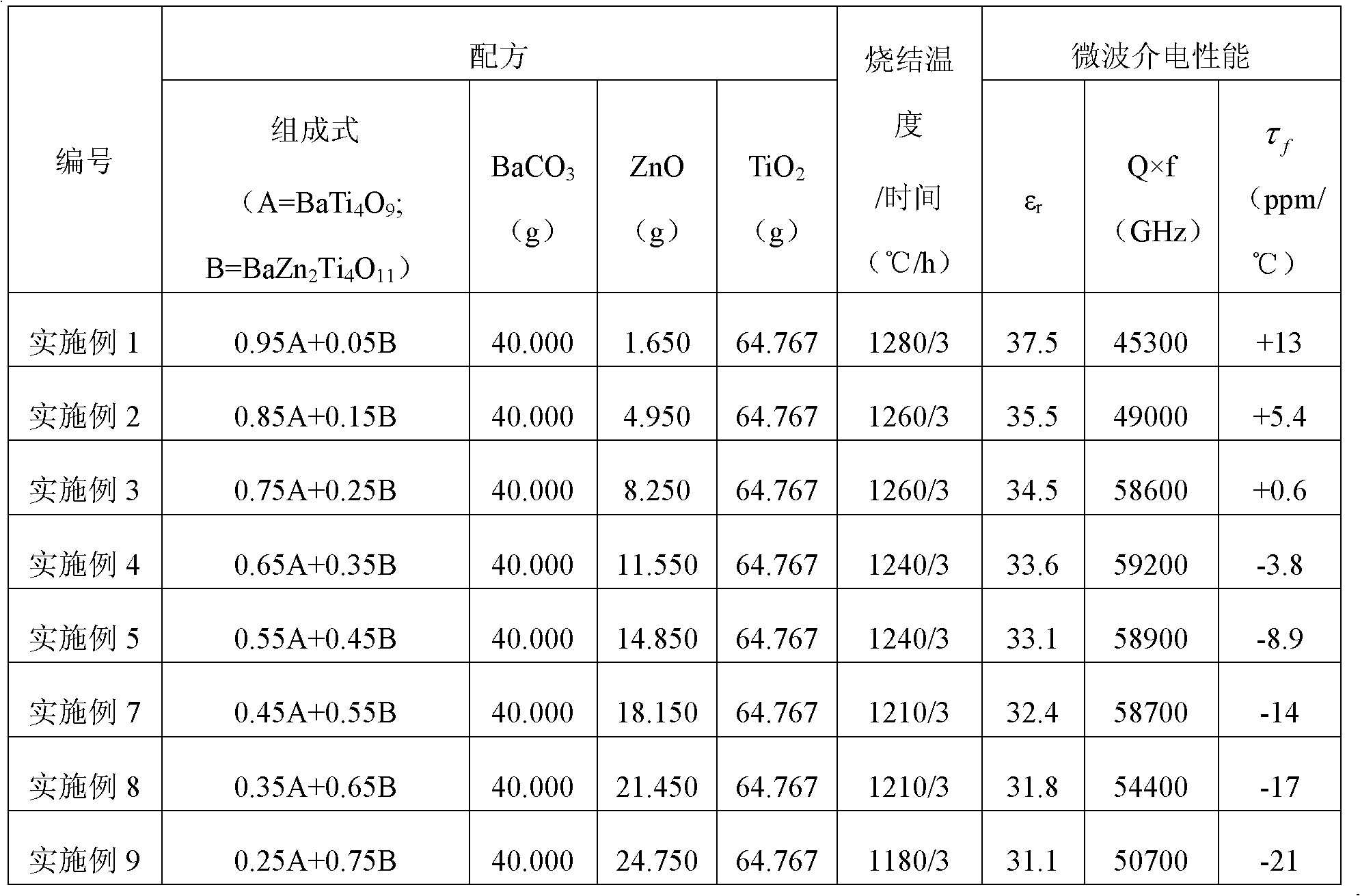

Embodiment 1~9

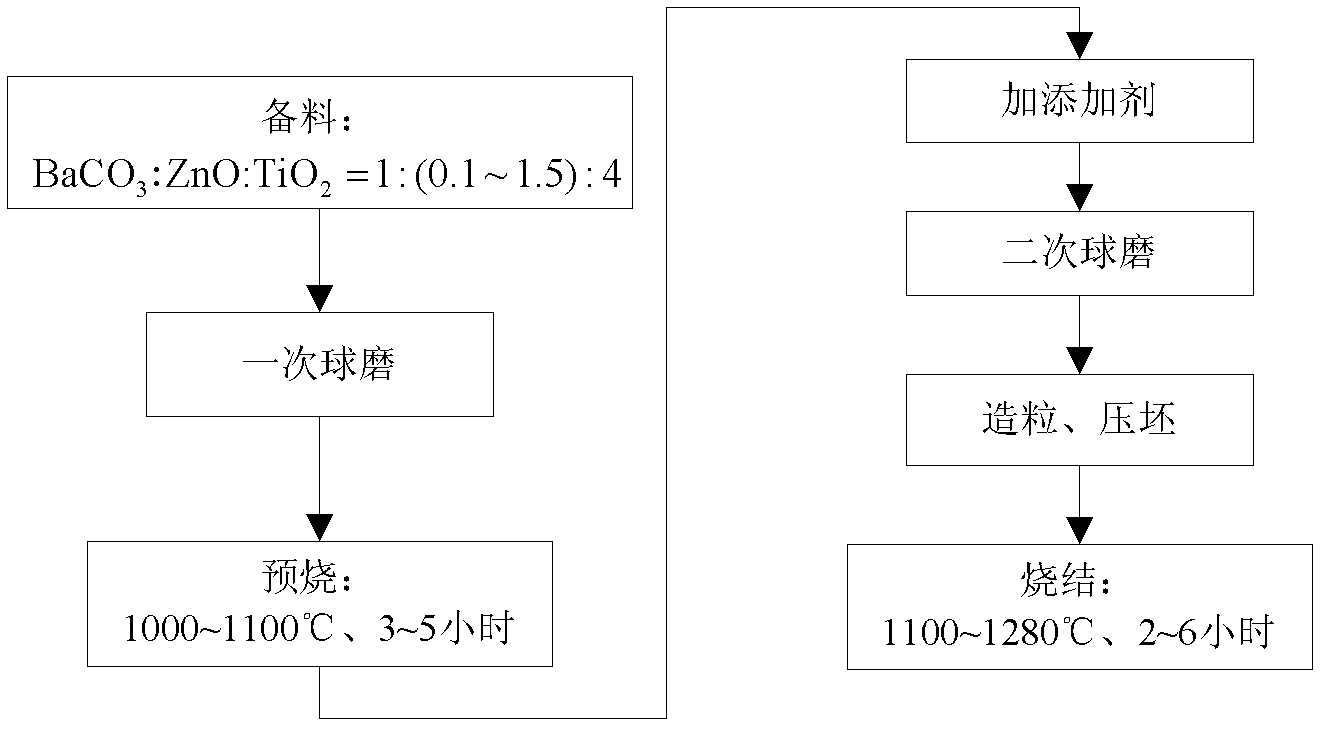

[0035] The concrete implementation steps that make these embodiment microwave dielectric ceramics are as follows:

[0036] (1) Select BaCO3, ZnO and TiO2 with a purity greater than 99% as raw materials, according to BaCO 3 :ZnO:TiO 2 =1: (0.1~1.5): the mol ratio of 4 carries out raw material preparation, and concrete formula sees Table 1 for details;

[0037] (2) Put the prepared material into the nylon ball mill tank, and use zirconium balls as the balls and deionized water as the ball mill medium, and perform a ball mill for 20 hours according to the weight ratio of material: ball: water=1:5:1.4; After the primary ball milling, take out the primary ball grinding material, dry it at 100°C and pass through a 40-mesh sieve;

[0038] (3) Put the primary ball abrasive that was dried at 100°C and passed through a 40-mesh sieve into the crucible, and pre-fired at 1000°C for 3 hours;

[0039] (4) Carry out the secondary ball milling for 10 hours according to the weight ratio of m...

Embodiment 10~17

[0046] The concrete implementation steps that make these embodiment microwave dielectric ceramics are as follows:

[0047] (1) Select BaCO3, ZnO and TiO2 with a purity greater than 99% as raw materials, according to BaCO 3 :ZnO:TiO 2 =1: The mol ratio of 0.5: 4 carries out material preparation, promptly selects embodiment 3 as base material;

[0048] (2) Carry out a ball mill for 20 hours according to the weight ratio of material: ball: water=1:5:1.4; after the first ball mill, take out the ball mill material and dry it at 100°C and pass through a 40-mesh sieve;

[0049] (3) Put the primary ball abrasive that was dried at 100°C and passed through a 40-mesh sieve into the crucible, and pre-fired at 1100°C for 5 hours;

[0050] (4) After adding 0.0 to 2.0% MnO2, 0.0 to 1.5% Nd2O3 and 0.0 to 3.0% CuO to the pre-sintered material, according to the weight of material: ball: water = 1: 5: 1.4 Perform secondary ball milling for 24 hours; after the secondary ball milling, take out ...

Embodiment 18~22

[0057] The concrete implementation steps that make these embodiment microwave dielectric ceramics are as follows:

[0058] (1) Select BaCO3, ZnO and TiO2 with a purity greater than 99% as raw materials, according to BaCO 3 :ZnO:TiO 2 =1: 11: 4 molar ratio prepares materials, promptly selects embodiment 7 as base material;

[0059] (2) Carry out a ball mill for 20 hours according to the weight ratio of material: ball: water=1:5:1.4; after the first ball mill, take out the ball mill material and dry it at 100°C and pass through a 40-mesh sieve;

[0060] (3) Put the primary ball abrasive that was dried at 100°C and passed through a 40-mesh sieve into the crucible, and pre-fired at 1100°C for 5 hours;

[0061](4) After adding 0.0 to 2.0% MnO2, 0.0 to 1.5% Nd2O3 and 0.0 to 3.0% CuO to the calcined material, according to the weight of material: ball: water = 1:5:1.4 Perform secondary ball milling for 24 hours; after the secondary ball milling, take out the secondary ball grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| sintering temperature | aaaaa | aaaaa |

| frequency temperature coefficient | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com