Method for preparing modified alkyd resin

An alkyd resin and modification technology, which is applied in the field of polyester resin, can solve the problems of zero profit margin and increased product cost, and achieve the effects of short production cycle, energy saving, and overcoming the shortcomings of technology and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

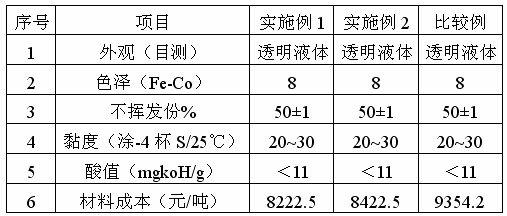

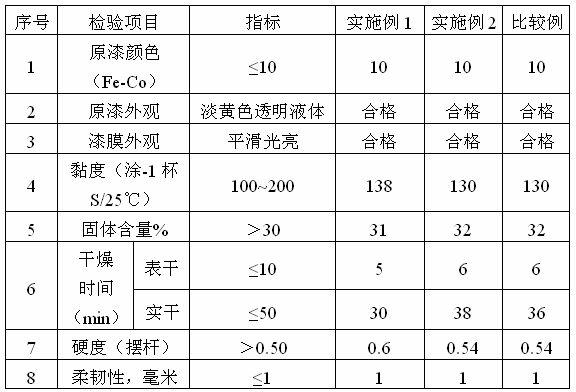

Examples

Embodiment 1

[0014] (1) Mix 24kg of ricinoleic acid, 29kg of glycerin, 30kg of phthalic anhydride, and 17kg of crude p-toluic acid into a stainless steel reaction kettle;

[0015] (2) Add 6kg of xylene and 0.08kg of hypophosphorous acid into the reaction vessel, seal the feeding port, open the vent valve, heat up and stir, gradually raise the temperature to 190°C for 2 hours in 6 hours, and then keep it at 200°C for 2 hours. When the acid value is below 21.5mgkOH / g, it is the end point of the reaction. After passing the test, the temperature is lowered, diluted with toluene, pressure filtered, and packaged;

[0016] The above crude p-toluic acid refers to p-toluic acid with a water content of 30wt%, and hypophosphorous acid is an aqueous solution of hypophosphorous acid with a concentration of 51wt%.

Embodiment 2

[0018] (1) Mix 37kg of ricinoleic acid, 22kg of glycerin, 31kg of phthalic anhydride, and 10kg of crude p-toluic acid into a stainless steel reaction kettle;

[0019] (2) Add 6kg of xylene and 0.06kg of hypophosphorous acid into the reaction vessel, seal the feeding port, open the vent valve, heat up and stir, gradually raise the temperature to 190°C for 2 hours in 6 hours, and then keep it warm at 208°C. When the acid value is below 21.5mgkOH / g, it is the end point of the reaction. After passing the test, the temperature is lowered, diluted with toluene, pressure filtered, and packaged;

[0020] The above crude p-toluic acid refers to p-toluic acid with a water content of 30wt%, and hypophosphorous acid is an aqueous solution of hypophosphorous acid with a concentration of 51wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com