Preparation method for surface-grafted polyacrylic acid lead polyester film

A technology of polyacrylic acid lead polyester and surface grafting, which is applied in the field of polyester film, and can solve the problem that the stability of the film surface particles of the composite material film is difficult to meet the requirements of practical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

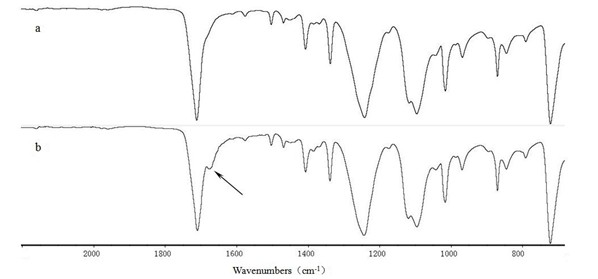

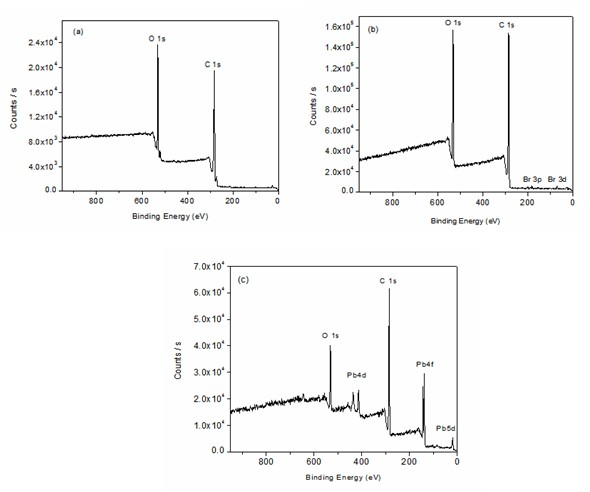

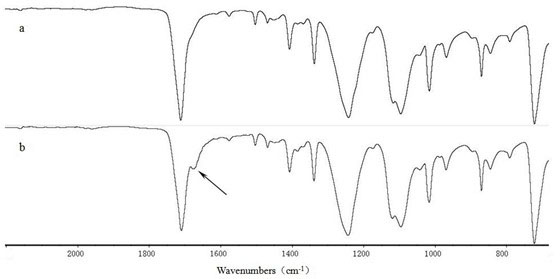

[0022] (1) Preparation of polyester film initiator: Submerge 100 cut polyester film sheets with a size of (1.5×1.5cm) in 2mol / L sodium hydroxide solution and analytically pure glacial acetic acid Each hydrolyzed for 1 hour at 70°C; then the film was placed in a dilute sulfuric acid solution with a potassium permanganate concentration of 50 g / L (1.2 mol / L of dilute sulfuric acid), and oxidized for 1 hour at 60°C , take out and wash with dilute hydrochloric acid, water and acetone several times respectively, place in an oven and dry at 80°C for 12 hours, and then use a dichloromethane solution of phosphorus pentachloride with a mass volume ratio (w / v) of 3% to dissolve the polyester Membrane acid chlorination, sealed reaction at room temperature for 18 hours, the membrane was washed several times with dichloromethane and acetone respectively. Then place the polyester film in a sodium hydroxide solution containing diethanolamine at a concentration of 40g / L (the concentration of t...

Embodiment 2

[0026] (1) Preparation of polyester film initiator: about 100 cut polyester film sheets with a size of (1.5×1.5cm) were immersed in 2mol / L sodium hydroxide solution and analytically pure ice In acetic acid, hydrolyze each at 70°C for 1 hour; then place the film in dilute sulfuric acid solution with potassium permanganate concentration of 50g / L (dilute sulfuric acid concentration is 1.2mol / L), and oxidize at 60°C for 1 hour After that, take it out and wash it several times with dilute hydrochloric acid, water, and acetone respectively, place it in an oven and dry it for 12 hours at 80°C, and then use a dichloromethane solution of phosphorus pentachloride with a mass volume ratio (w / v) of 3% to dissolve the poly Acyl chlorination of the polyester film, after 18 hours of airtight reaction at room temperature, the film was washed several times with dichloromethane and acetone respectively, and then the polyester film was placed in a sodium hydroxide solution containing diethanolami...

Embodiment 3

[0030] (1) Preparation of polyester film initiator: about 100 cut polyester film sheets with a size of (1.5×1.5cm) were immersed in 2mol / L sodium hydroxide solution and analytically pure ice In acetic acid, hydrolyze each at 70°C for 1 hour; then place the film in dilute sulfuric acid solution with potassium permanganate concentration of 50g / L (dilute sulfuric acid concentration is 1.2mol / L), and oxidize at 60°C for 1 hour After that, take it out and wash it several times with dilute hydrochloric acid, water, and acetone respectively, place it in an oven and dry it for 12 hours at 80°C, and then use a dichloromethane solution of phosphorus pentachloride with a mass volume ratio (w / v) of 3% to dissolve the poly Acyl chlorination of the polyester film, after 18 hours of airtight reaction at room temperature, the film was washed several times with dichloromethane and acetone respectively, and then the polyester film was placed in a sodium hydroxide solution containing diethanolami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com