Preparation method of surface hydrophilic silicon rubber

A silicone rubber and hydrophilic technology, applied in the field of surface hydrophilic silicone rubber preparation, can solve the problems of poor oil resistance, solvent resistance, acid and alkali resistance, uneven surface grafted polymer layer, difficult vulcanization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

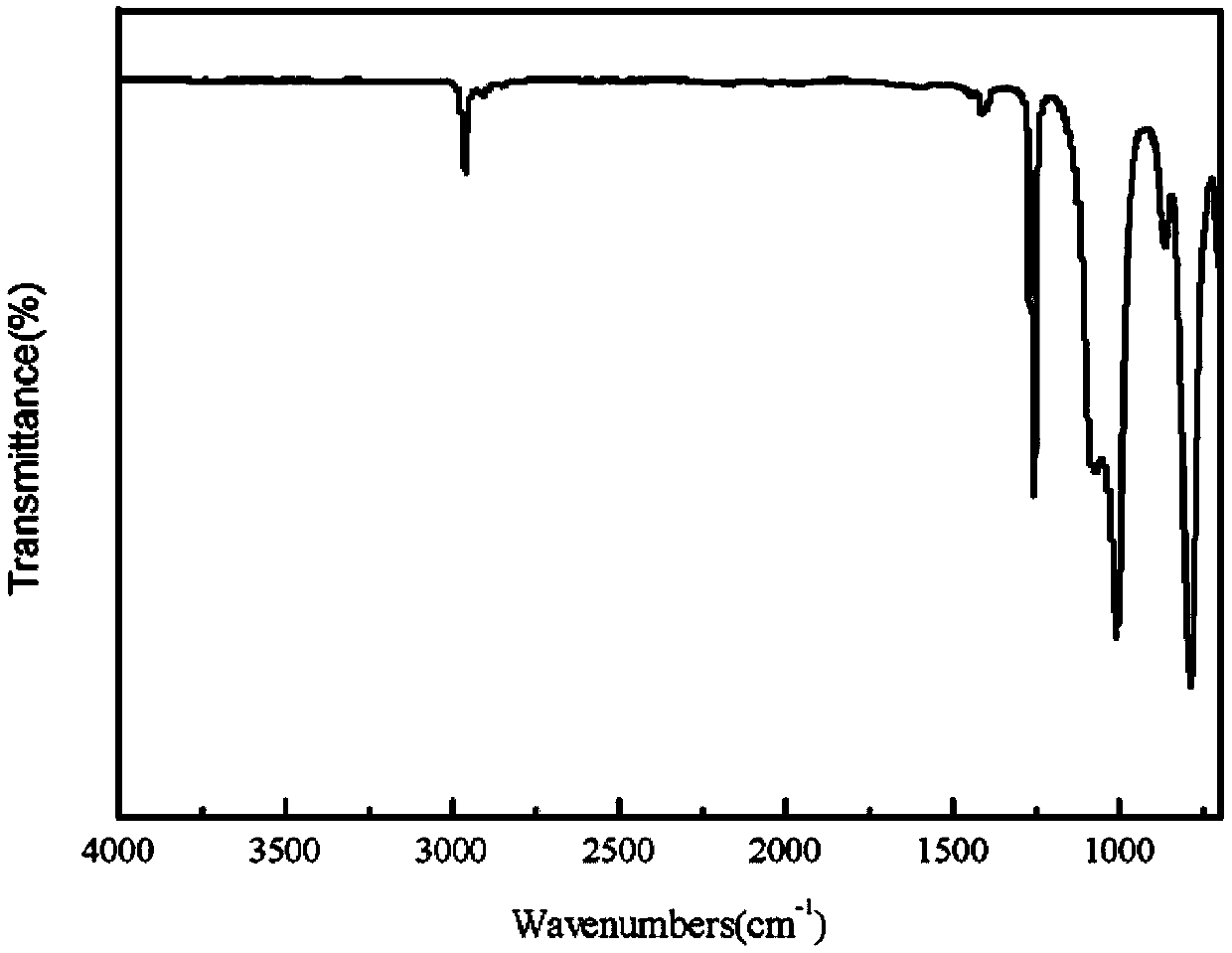

[0032] Step (1) Add hydroxyl-terminated polydimethylsiloxane to a three-necked flask equipped with an electric stirrer, vacuum dehydrate at 80°C for 1 hour, add 7% methyl tributylketoxime silane, pass N 2 After stirring for 0.5h, add 0.1% dibutyltin dilaurate, pass N 2 Stir and react for 15 minutes, vacuum degassing, pour into a 2mm thick mold, and cure at room temperature for 7 days.

[0033] Step (2) Add the room temperature vulcanized silicone rubber prepared in step (1) into the reaction bottle, and add 50mL of 10% hydrochloric acid. Stir at room temperature for 4 h, and after the reaction, ultrasonically wash and dry under vacuum at 50°C.

[0034] Step (3) Add the surface-activated silicone rubber sheet in step (2) to a dry reaction bottle, add 30mL ethyl acetate, 1.3mL triethylamine and stir in an ice bath, add dropwise 1mL α-bromoisobutyryl A mixed solution of bromine and 10 mL of ethyl acetate was removed from the ice bath after 0.5 h of dripping. The reaction was c...

Embodiment 2

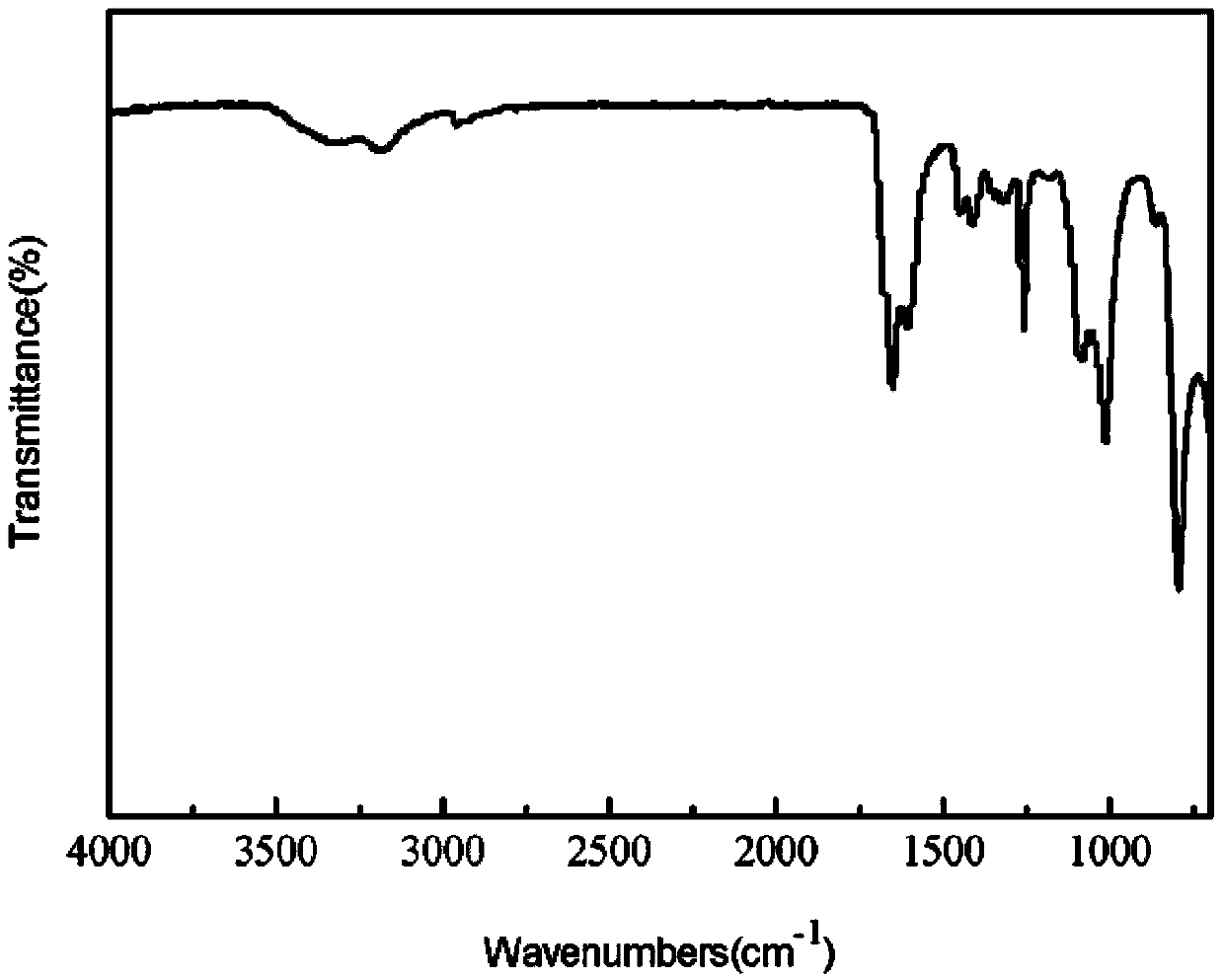

[0041] Step (1) Add hydroxyl-terminated polydimethylsiloxane to a three-necked flask equipped with an electric stirrer, vacuum dehydrate at 80°C for 3 hours, add 5% methyl tributylketoximosilane, pass N 2 After stirring for 0.5h, add 0.1% dibutyltin dilaurate, pass N 2 Stir and react for 20 minutes, vacuum degassing, pour into a mold with a thickness of 2 mm, and cure at room temperature for 10 days.

[0042] Step (2) Add the room temperature vulcanized silicone rubber prepared in step (1) into the reactor, and add 50mL of 10% hydrochloric acid. Stir at room temperature for 6 h, and after the reaction is completed, ultrasonically wash and dry under vacuum at 50°C.

[0043] Step (3) Add the surface-activated silicone rubber sheet in step (2) into a dry single-necked flask, add 30 mL of toluene, 1.3 mL of triethylamine and stir in an ice bath, add dropwise 1 mL of α-bromoisobutyryl bromide and 10mL of toluene mixed solution, after 0.5h drop, remove the ice bath. The reaction ...

Embodiment 3

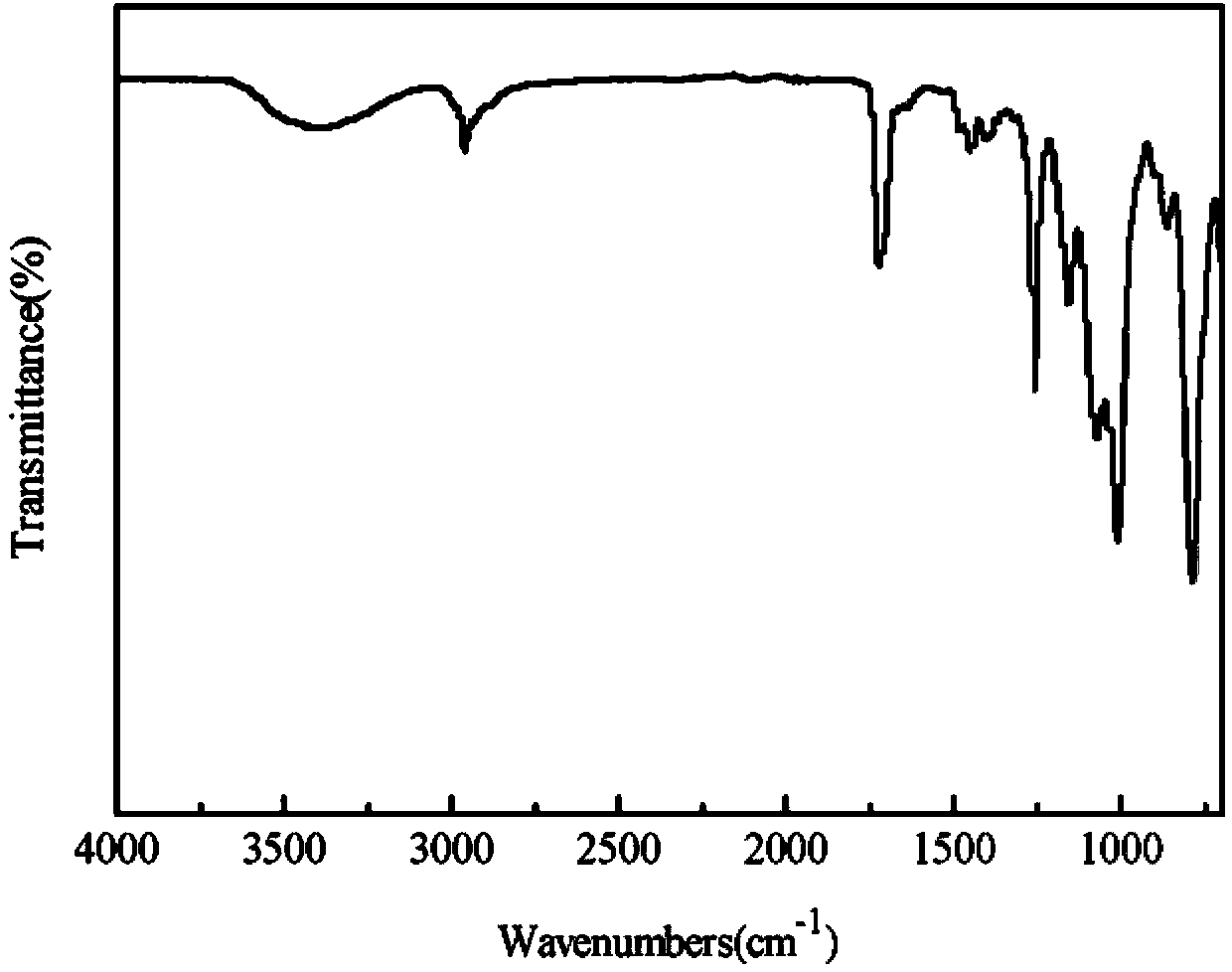

[0046] Step (1) Add hydroxyl-terminated polydimethylsiloxane to a three-necked flask equipped with an electric stirrer, vacuum dehydrate at 100°C for 1 hour, add 7% methyl tributylketoximosilane, pass N 2 After stirring for 0.5h, add 0.05% dibutyltin dilaurate, pass N 2 Stir the reaction for 15 minutes, then vacuum degass it and inject it into a mold with a thickness of 2 mm, and cure it at room temperature for 7 days.

[0047] Step (2) The room temperature vulcanized silicone rubber prepared in step (1) was irradiated with ultraviolet light for 10 minutes to activate the surface of the silicone rubber.

[0048] Step (3) Add the surface-activated silicone rubber sheet in step (2) into a dry single-necked flask, add 30 mL of acetone, 1.3 mL of triethylamine and stir in an ice bath, dropwise add 1 mL of α-bromoisobutyryl bromide and 10mL of acetone mixed solution, after 0.5h drop, remove the ice bath. The reaction was carried out under magnetic stirring at room temperature for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com