Polystyrene-maleic anhydride derivative water-coal-slurry additive and preparation method thereof

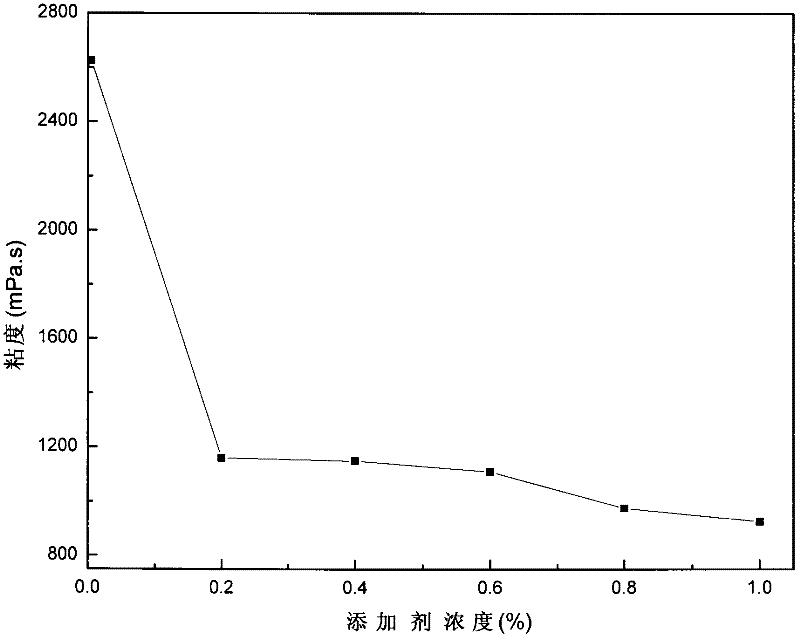

A technology of maleic anhydride and polystyrene, used in the field of coal-water slurry additives and their preparation, can solve the problems of reduced Zeta potential, reduced stability, and weakened coal particle repulsion, and reduced apparent viscosity and shear viscosity. , the effect of improving fluidity and reducing coal-water interfacial tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

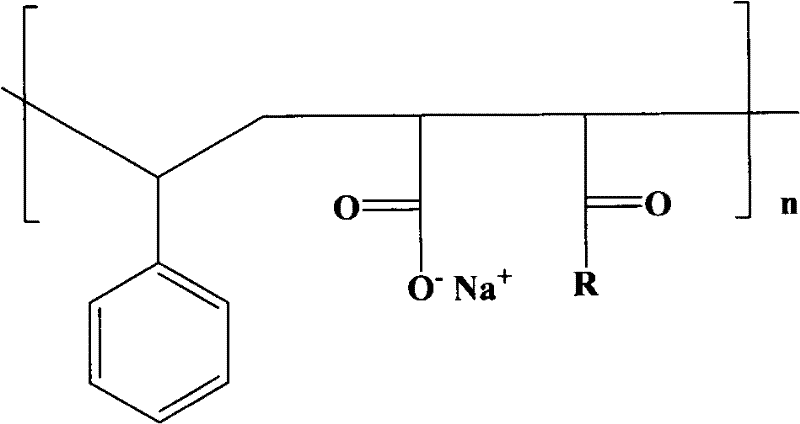

[0037] Take 60 grams of polystyrene-maleic anhydride, dissolve it in 300ml of organic solvent, stir in an oil bath at 40-60°C at a speed of 250-300 rpm, and keep it warm for 20-30 minutes;

[0038] Take 30-90 grams of aminonaphthalenesulfonic acid, dissolve it in 1000ml of alkali solution with a mass fraction of 1.5-3%, and slowly add it dropwise with a dropping funnel, and control the dropping speed so that it will be dripped in 15-30 minutes. React for 6-18 hours under the conditions of stirring at a temperature of 40-60° C. in a bath at a speed of 250-300 rpm.

Embodiment 2

[0040] Take 60 grams of polystyrene-maleic anhydride, dissolve it in 300ml of acetone, stir it at a speed of 300 rpm in an oil bath at 50°C, and keep it warm for 20 minutes;

[0041]Get the 5-amino-1-naphthalenesulfonic acid of 60 grams, be dissolved in 1000ml mass fraction and be in the sodium hydroxide solution of 2.5%, slowly add dropwise with dropping funnel, control drop rate and make it drip in 25 minutes, in The reaction was carried out for 8 hours in an oil bath at 50° C. and stirring at a speed of 300 rpm.

Embodiment 3

[0043] Take 60 grams of polystyrene-maleic anhydride, dissolve it in 300ml N,N-dimethylformamide, stir at a speed of 280 rpm in an oil bath at 50°C, and keep it warm for 25 minutes;

[0044] Get the 4-amino-1-naphthalenesulfonic acid of 30 grams, be dissolved in 1000ml mass fraction and be in the sodium hydroxide solution of 2%, slowly add dropwise with dropping funnel, control drop rate and make it drip in 20 minutes, in The reaction was carried out for 6 hours in an oil bath at 50° C. and stirring at a speed of 280 rpm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com