12V direct-current air cooling control module

A technology of control module and direct current wind, applied in pump control, electrical program control, program control in sequence/logic controller, etc., can solve problems such as insufficient fan monitoring and control, low fan life, interference impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

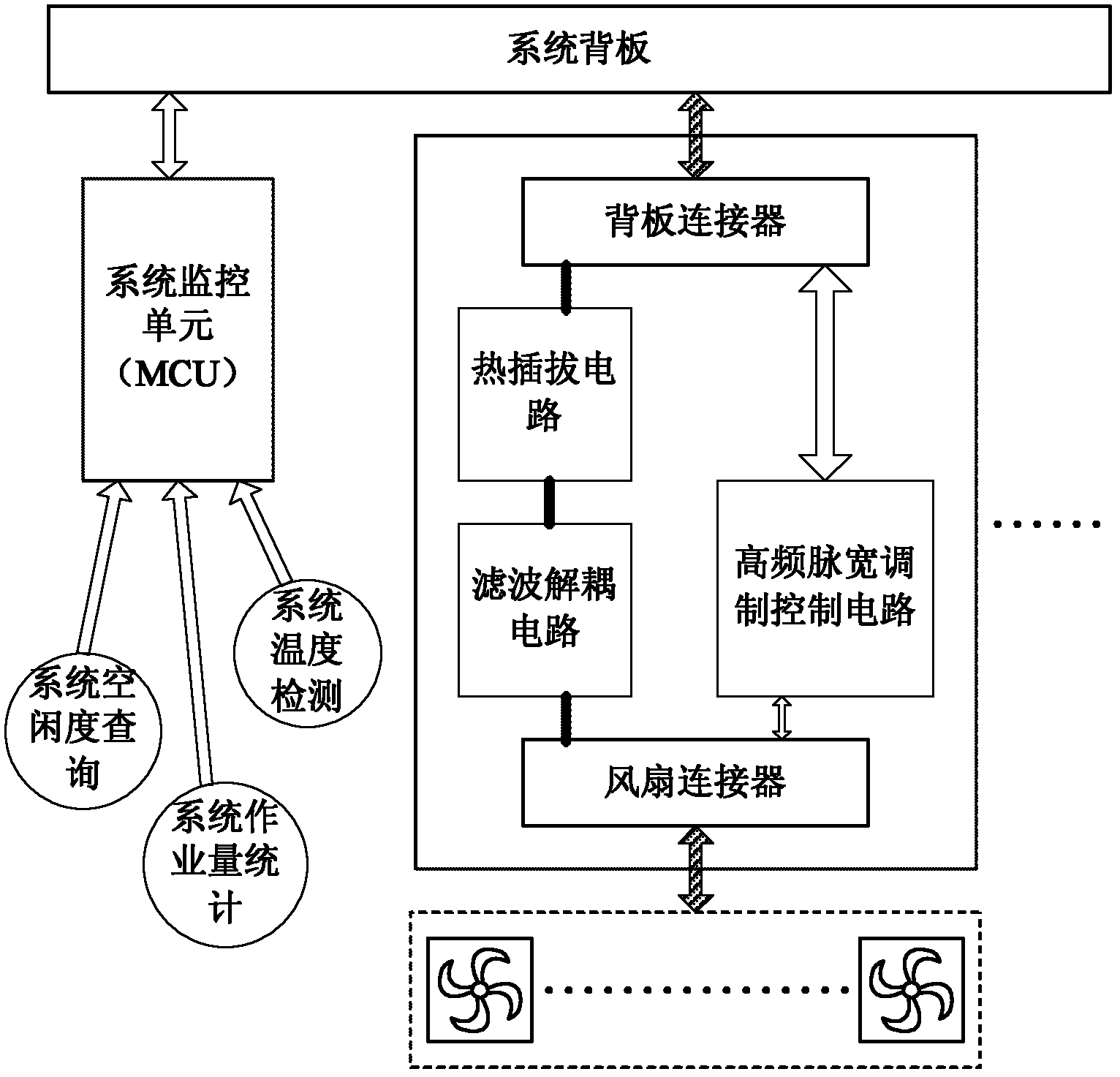

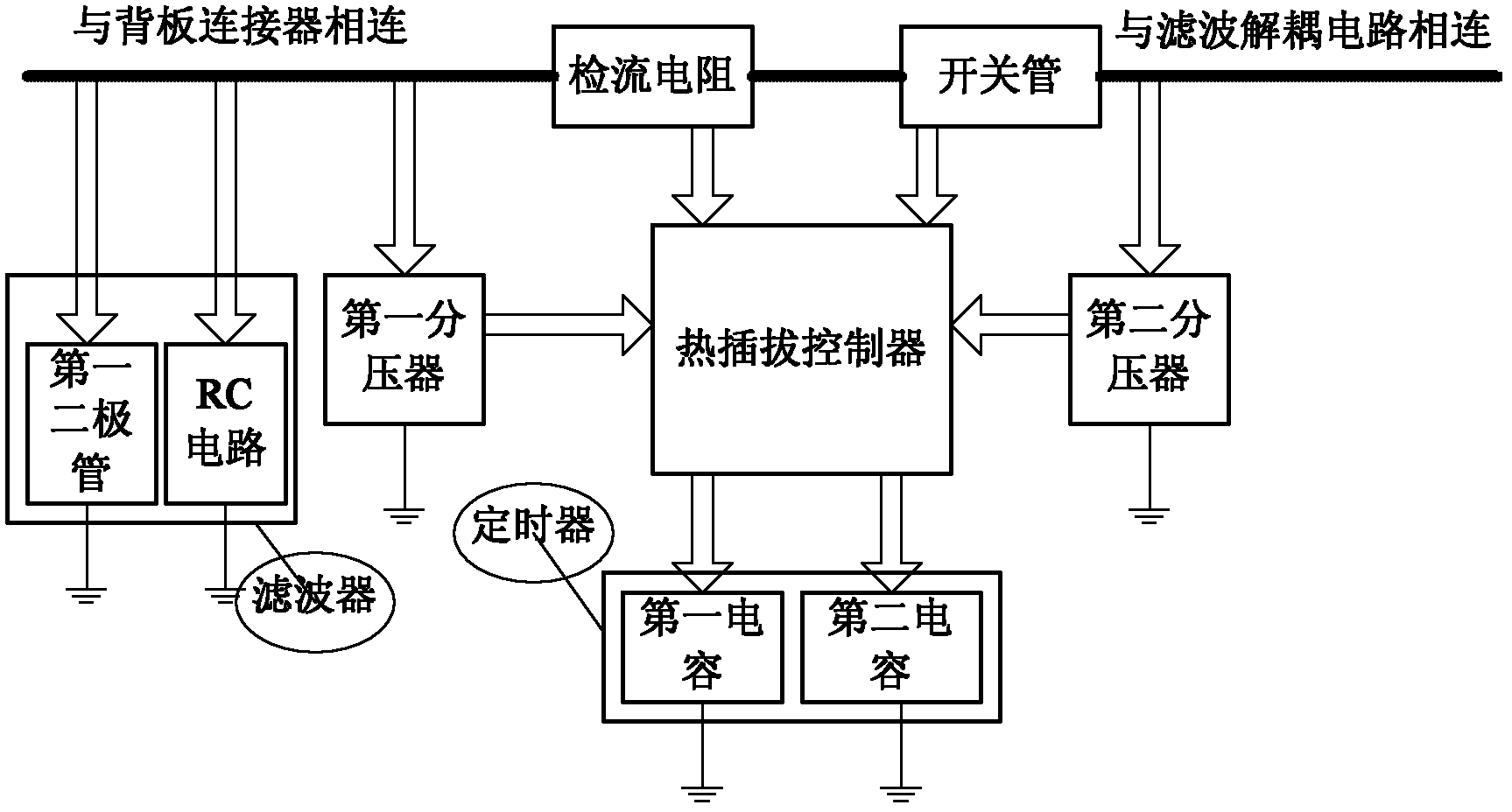

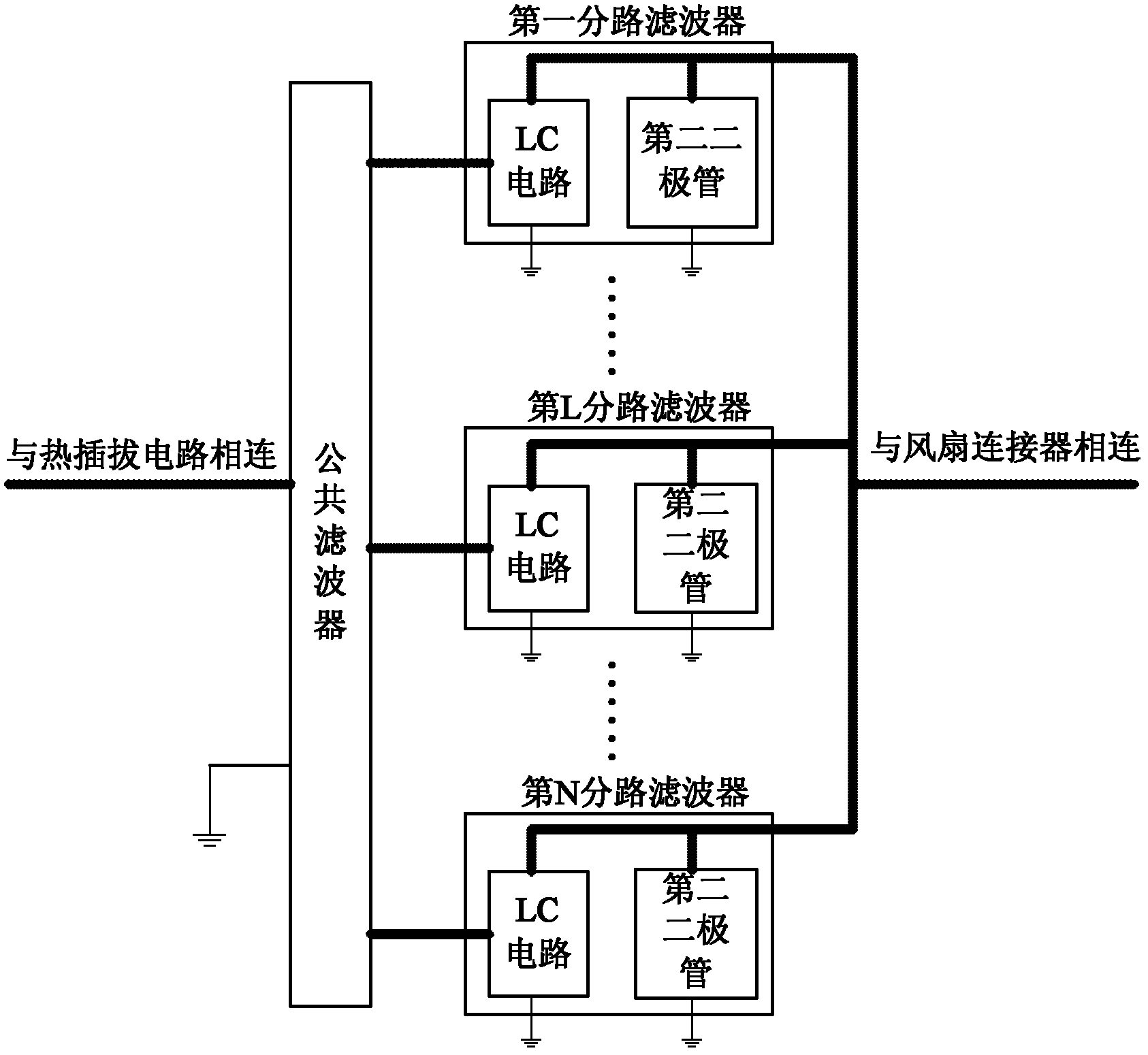

[0026] Such as figure 1 As shown, the 12V DC air-cooled control module of the present invention is installed in the subframe providing cooling service in the high-performance computer system cabinet, and connected with the backplane of the computer. The invention is composed of a backplane connector, a hot plug circuit, a filter decoupling circuit, a high-frequency pulse width modulation (Pulse Width Modulation, PWM) control circuit, and a fan connector, all of which are integrated on one printed circuit board. The present invention is connected with the system backplane through the backplane connector, and the present invention is connected with the fan group through the fan connector.

[0027] The backplane connector adopts a commercial connector (such as FCI's product number 51700), which requires a load current capacity of no less than 20A and no less than 6 signal pins. The backplane connector is connected with the backplane of the computer system, the internal hot-swap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com