Method for preparing sodium hydrosulphite by utilization of tail gas from acyl chloride production

A technology of sodium sulfite and sodium bisulfite, which is applied in the preparation, separation method, chemical instrument and method of alkali metal sulfite, can solve the problem that calcium sulfite is not very useful, the absorption rate of sulfur dioxide is not high, and the absorption efficiency of sulfur dioxide is not high. Advanced problems, to achieve the effect of stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

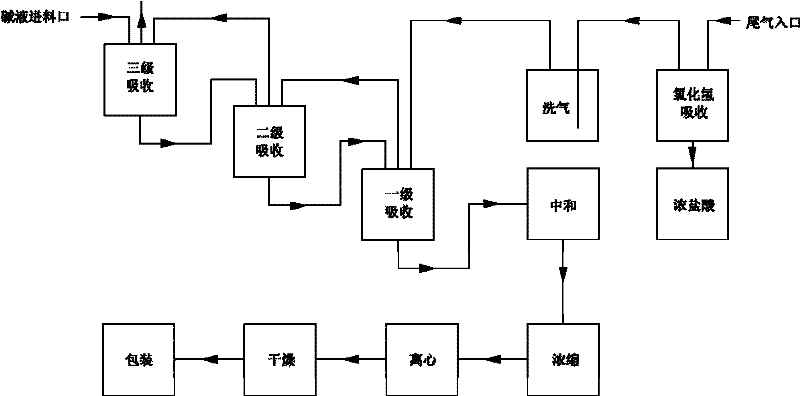

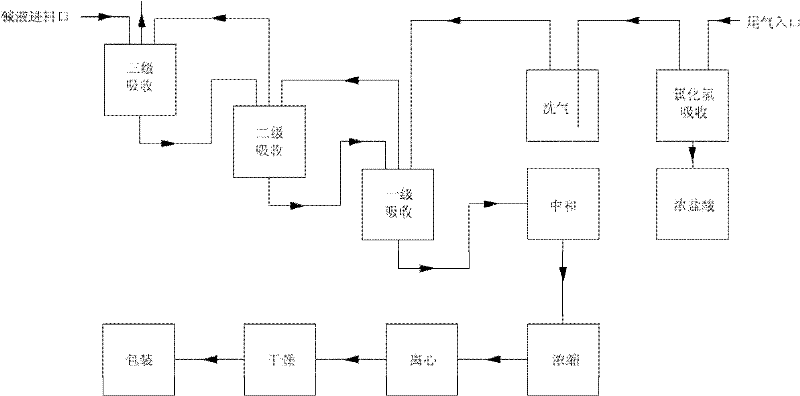

Method used

Image

Examples

Embodiment 1

[0020] (1) acid chloride production tail gas is absorbed through falling film water, removes HCl gas wherein, and generation mass fraction is the concentrated hydrochloric acid of 30%;

[0021] (2) remove a small amount of HCl gas mixed with sulfur dioxide with saturated sodium bisulfite solution;

[0022] (3) The acid chloride production tail gas that step (2) has been processed is passed into continuous feeding and continuous discharge and concentration is equipped with in the absorption kettle of the sodium carbonate solution of 200g / L, under normal pressure, 40 ℃ of conditions, carry out three The stage continuously absorbs sulfur dioxide, generates and releases a feed liquid containing sodium bisulfite, and controls the pH of the discharged feed liquid to be 5.9;

[0023] (4) The feed liquid released in step (3) is neutralized with a 30% NaOH solution until the pH value is 10.0 to obtain a neutralized liquid.

[0024] Through the above steps, the absorption rate of sulfu...

Embodiment 2

[0026] (1) acid chloride production tail gas is absorbed through falling film water, removes HCl gas wherein, and generation mass fraction is the concentrated hydrochloric acid of 32%;

[0027] (2) remove a small amount of HCl gas mixed with sulfur dioxide with saturated sodium bisulfite solution;

[0028] (3) The acid chloride production tail gas that step (2) has been processed is passed into the absorption kettle of the sodium carbonate solution of 250g / L with continuous feeding and continuous discharging and is equipped with concentration, under normal pressure, 110 ℃ of conditions, carry out three The stage continuously absorbs sulfur dioxide, generates and releases a feed liquid containing sodium bisulfite, and controls the pH of the discharged feed liquid to be 3.9;

[0029] (4) the feed liquid that step (3) emits is the Na of 30% with massfraction 2 CO 3 The solution is neutralized until the pH value is 8.0 to obtain a neutralized solution.

[0030] Through the abov...

Embodiment 3

[0032] (1) acid chloride production tail gas is absorbed through falling film water, removes HCl gas wherein, and generation mass fraction is the concentrated hydrochloric acid of 28%;

[0033] (2) remove a small amount of HCl gas mixed with sulfur dioxide with saturated sodium bisulfite solution;

[0034] (3) The acid chloride production tail gas that step (2) has been processed is passed into continuous feed and continuous discharge and concentration is equipped with in the absorption kettle of the sodium carbonate solution of 225g / L, under normal pressure, 70 ℃ of conditions, carry out three The stage continuously absorbs sulfur dioxide, generates and releases a feed liquid containing sodium bisulfite, and controls the pH of the discharged feed liquid to be 4.9;

[0035] (4) the feed liquid that step (3) emits is 35% Na with massfraction 2 CO 3 The solution is neutralized until the pH value is 9.0 to obtain a neutralized solution.

[0036] Through the above steps, the ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com