Modified active carbon and preparation method and application thereof

A technology of activated carbon and activated carbon powder, applied in the field of drinking water treatment, can solve the problems of difficult microbial cultivation and screening, introduction of pathogenic bacteria, low removal efficiency, etc., and achieve the effects of avoiding solid waste pollution, increasing adsorption capacity, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

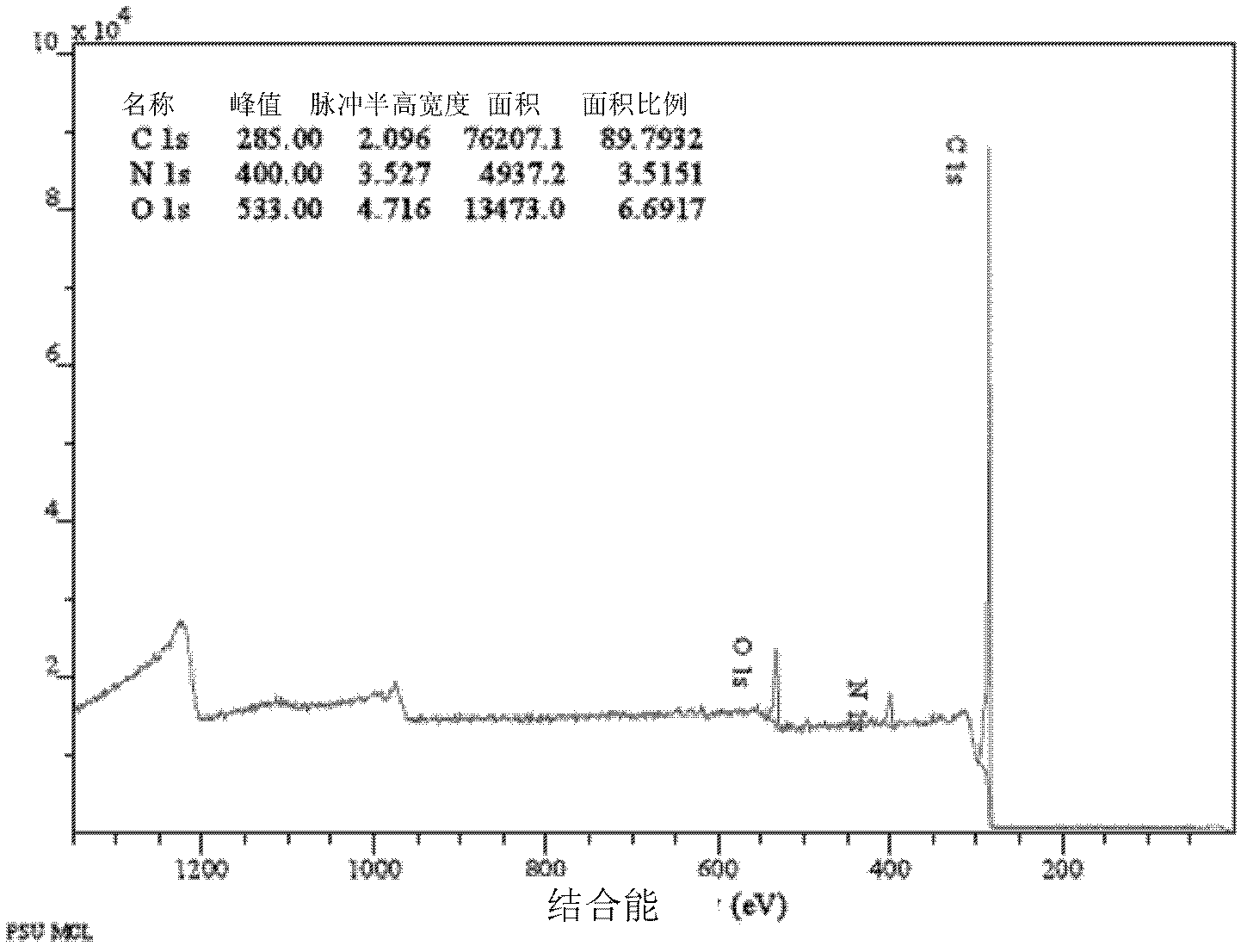

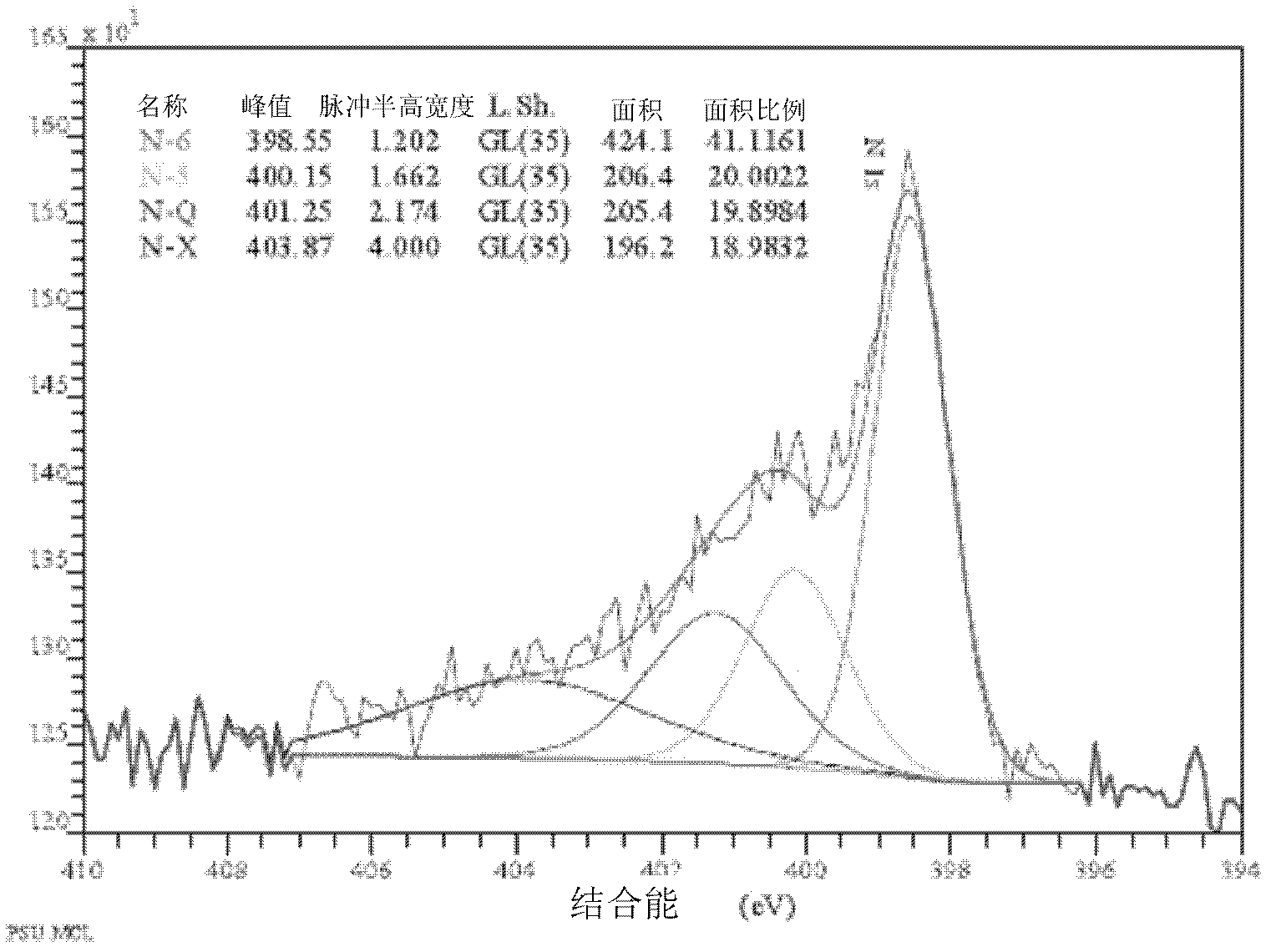

[0027] A modified activated carbon of the present invention contains a quaternary ammonium salt structure and a pyridine structure on the surface, and the quaternary ammonium salt structure and the pyridine structure are obtained by oxidizing, amination and methylating the surface of the activated carbon.

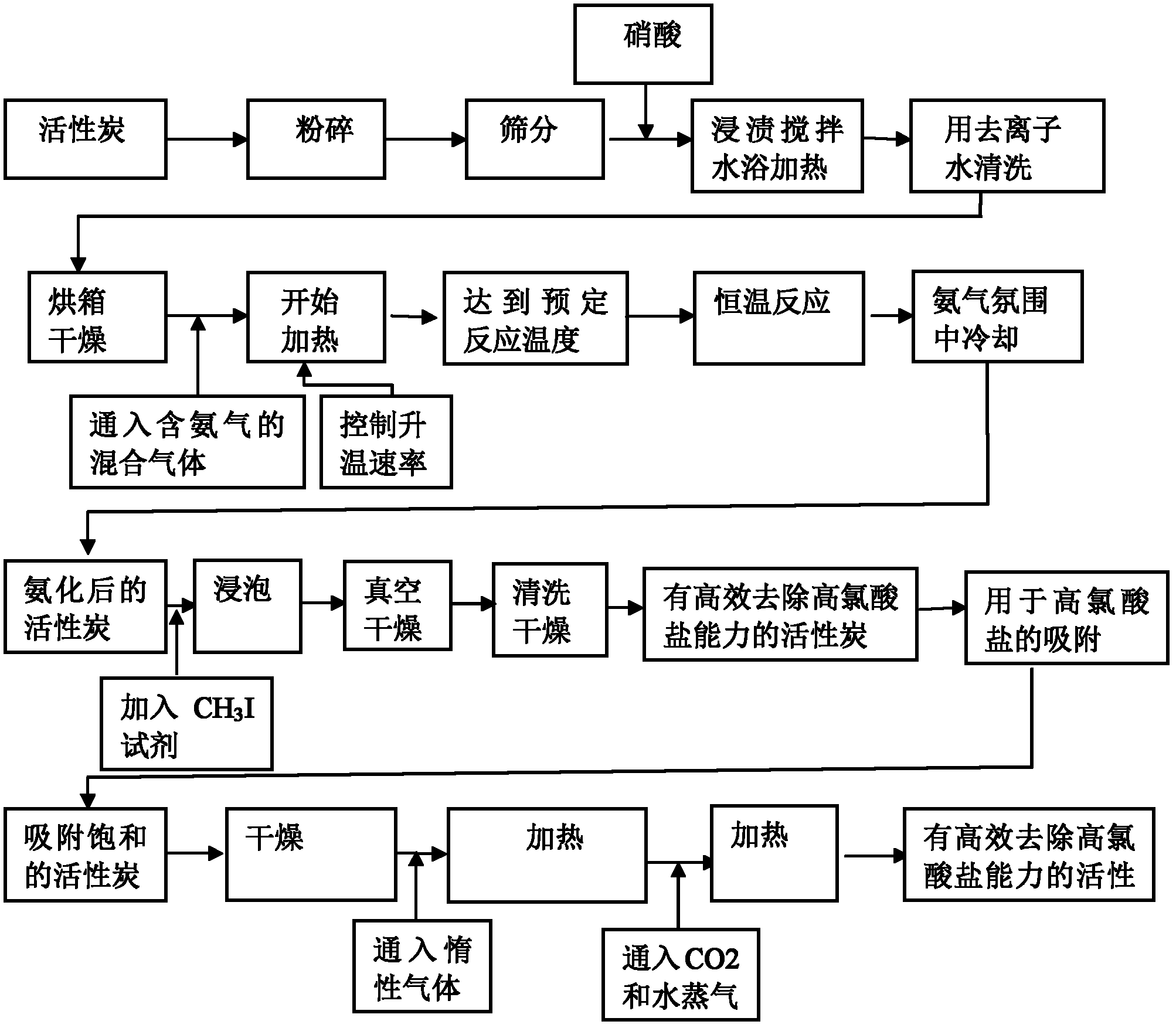

[0028] The preparation method of the above modified activated carbon is as follows figure 1 As shown, it specifically includes the following steps:

[0029] (1) Select coconut shell activated carbon, grind and grind it, pass through 200 mesh and 400 mesh sieves, sieving, and place in an oven at 100°C for 24 hours; take 10g of dried activated carbon and place it in a 500ml beaker. Add 300ml of nitric acid solution with a concentration of 8mol / L, place the beaker in a water bath at 60℃~80℃, soak and stir for 20 hours, take out the activated carbon to cool, then wash the activated carbon with deionized water 3 to 4 times, and then place it at 100℃ Dry for 24 hours in an oven at a c...

Embodiment 2

[0045] The modified activated carbon prepared in Example 1 was used to remove perchlorate in drinking water, and the prepared modified activated carbon was added to drinking water containing perchlorate for testing (including adsorption reaction and modified activated carbon regeneration) (Such as figure 1 Shown), specifically including the following steps:

[0046] (1) Adsorption test

[0047] A plexiglass column is used to make an adsorption column with a length of 8.2cm and a diameter of 0.357cm. The volume of the adsorption column is 0.82cm 3 , Obtain water samples from drinking water sources, and the content of perchlorate in the water samples is 0.075mg / L, Cl - The concentration is 7.2mg / L, NO 3 - The concentration is 25.7mg / L, SO 4 2- The concentration is 30mgl / L, HCO 3 - The concentration of is 145mg / L, and the modified activated carbon prepared in Example 1 is added to the adsorption column to perform the adsorption reaction;

[0048] During the detection process, the volume...

Embodiment 3

[0052] A method for preparing the modified activated carbon of the present invention is carried out according to the steps of Example 1. The difference from Example 1 is that the gas introduced in the ammoniating process is ammonia and oxygen, and the volume ratio is V NH3 : V O2 =1:1, the flow rates of ammonia and air are both controlled to 10ml / min, and the ammoniated process is carried out after mixing uniformly; the modified activated carbon obtained is tested according to the method of Example 2. The results show that the final activated carbon penetrates completely The volume of the water sample passed was 7900BV, and the adsorption capacity of activated carbon was expanded by 6.3 times. After regeneration, the adsorption capacity was 6650BV, which was 84.2% restored.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com