Operating method for high-efficient anaerobic ammonium oxidation reactor

A technology of anaerobic ammonium oxidation and anaerobic reactor, which is applied in the field of nitrogen removal in wastewater, can solve the problems of sensitive environmental conditions, difficulty in obtaining enriched cultures of anammox bacteria, and difficult denitrification performance. Achieve the effects of reducing operating costs, increasing total nitrogen load, and avoiding substrate inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

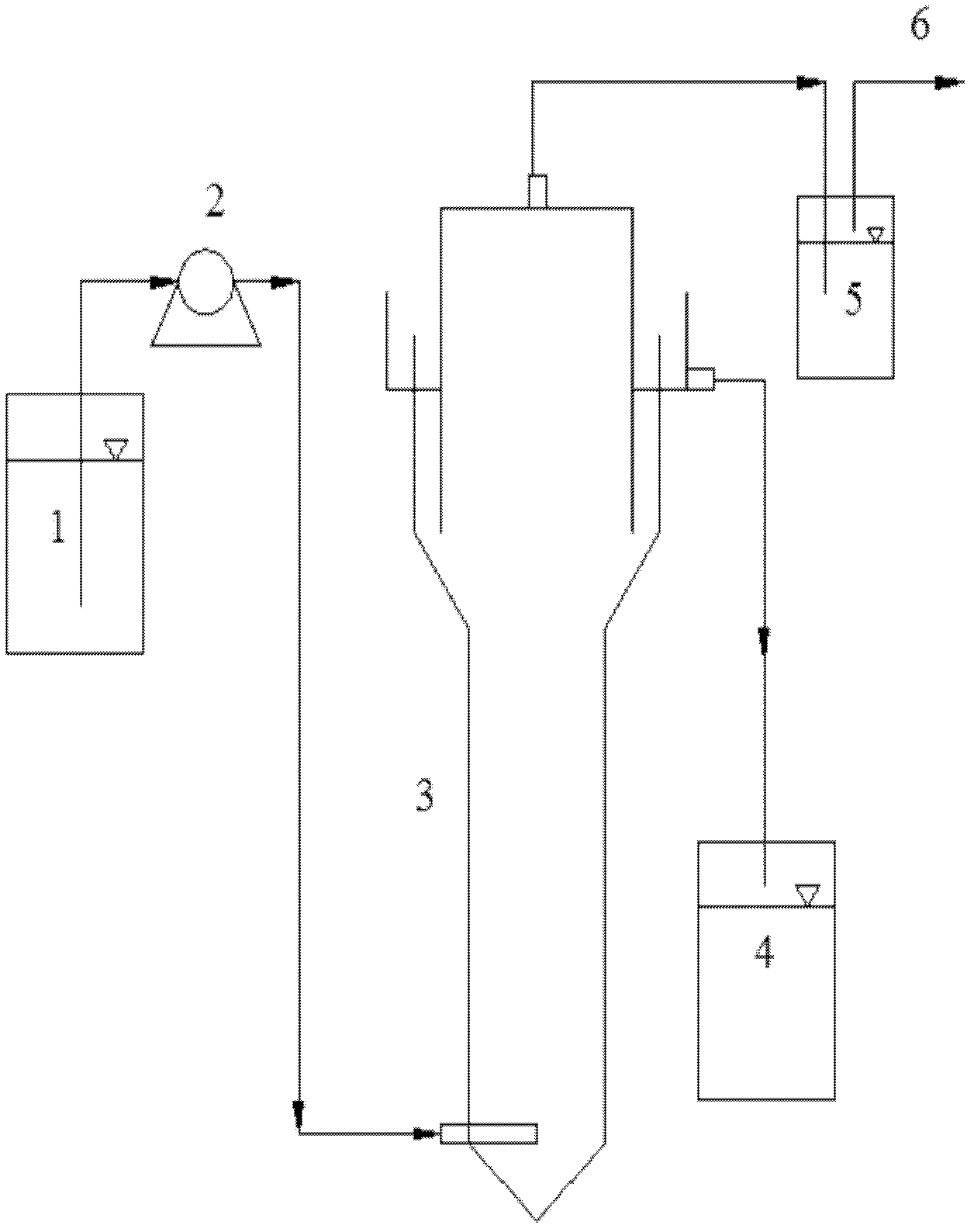

Image

Examples

Embodiment 1

[0023] (1) Inoculate anaerobic digested granular sludge in an upflow anaerobic activated sludge bed reactor. The sludge particle size is 2-3 mm, the sphericity is about 0.9, and the average specific gravity is about 1.6 (much greater than 1). It settles at the bottom of the reactor to form a sludge bed, and the volume of the sludge bed accounts for 60% of the total volume of the reactor.

[0024] (2) Ammonia nitrogen and nitrite nitrogen in simulated wastewater are represented by (NH 4 ) 2 SO 4 and NaNO 2 Provided, the molar ratio is 1:1, the initial concentration of ammonia nitrogen and nitrite nitrogen are both 70mg L -1 , the simulated wastewater is composed of components with the following mass composition: (NH 4 ) 2 SO 4 (70~350mg·L -1 ), NaNO 2 (70~350mg·L -1 ), KH 2 PO 4 10mg·L -1 , CaCl 2 2H 2 O 5.6mg·L -1 , MgSO 4 ·7H 2 O 300mg·L -1 , KHCO 3 1250mg·L -1, trace elements are added after being chelated with EDTA, and the composition of the trace ele...

Embodiment 2

[0028] Reactor, inoculated sludge, deaeration and temperature conditions and water inflow are all the same as in Example 1. When the reactor meets the conditions (A): nitrite nitrogen in the effluent is less than 30mg / L or (B): the effluent data (ammonia nitrogen or nitrite nitrogen concentration) is stable for three consecutive days and the concentration of nitrite nitrogen in the effluent is less than 60mg / L. Reactor operating load. The initial concentration of ammonia nitrogen and nitrite nitrogen are both 70mg·L -1 , The hydraulic retention time is 12h. After 90 days of operation, the anaerobic reactor formed anammox granular sludge enriched with anammox bacteria. The reactor runs for 1 to 180 days, the hydraulic retention time is gradually shortened from the initial 12 hours to 4 hours on the 180th day with a step of 2 hours, and the total nitrogen load of the influent is reduced from 0.42kg / (m 3 .d) increased to 0.89kg / (m 3 .d). Afterwards, gradually increase the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com