Method for using waste erythritol mother liquor as concrete retarder

A technology of erythritol and waste mother liquor, which is applied in the field of building materials, can solve the problems of poor stability of retardation and rarely used alone

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

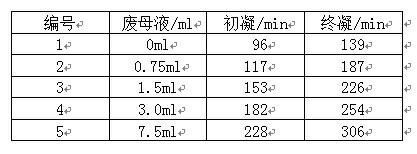

Image

Examples

Embodiment 1

[0014] The implementation parameters are: concrete strength grade C30, P.O32.5 cement, medium sand, 16-31.5mm gravel, room temperature and humidity. Mix 1420.0g of cement, 2560.0g of sand and 4940.0g of gravel, add 735.0mL of water and stir evenly, and finally add 5.0mL of erythritol waste mother liquor and mix well, and record the initial setting and final setting times of concrete as 113 minutes and In 198 minutes, compared with the concrete without erythritol waste mother liquor, the initial setting and final setting time of concrete were delayed by more than 35% and 30% respectively.

Embodiment 2

[0016] The implementation parameters are: concrete strength grade C30, P.O32.5 cement, medium sand, 16-31.5mm gravel, room temperature and humidity. Mix 1420.0g of cement, 2560.0g of sand and 4940.0g of gravel, add 690.0mL of water and stir evenly, and finally add 50.0mL of erythritol waste mother liquor and mix well, and record the initial setting and final setting times of concrete as 174 minutes and 274 minutes, compared with the concrete without erythritol waste mother liquor, the delay of initial setting and final setting time is increased after increasing the amount of waste mother liquor on the basis of Example 1, which can be delayed by more than 100% and 80% respectively .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com