Concrete anti-corrosion etching resisting agent and preparation method thereof

An anti-corrosion agent and anti-corrosion technology, applied in the field of concrete additives, can solve the problems of high production cost, non-environmental protection, non-conforming to energy saving and emission reduction, and achieve significant economic value and environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

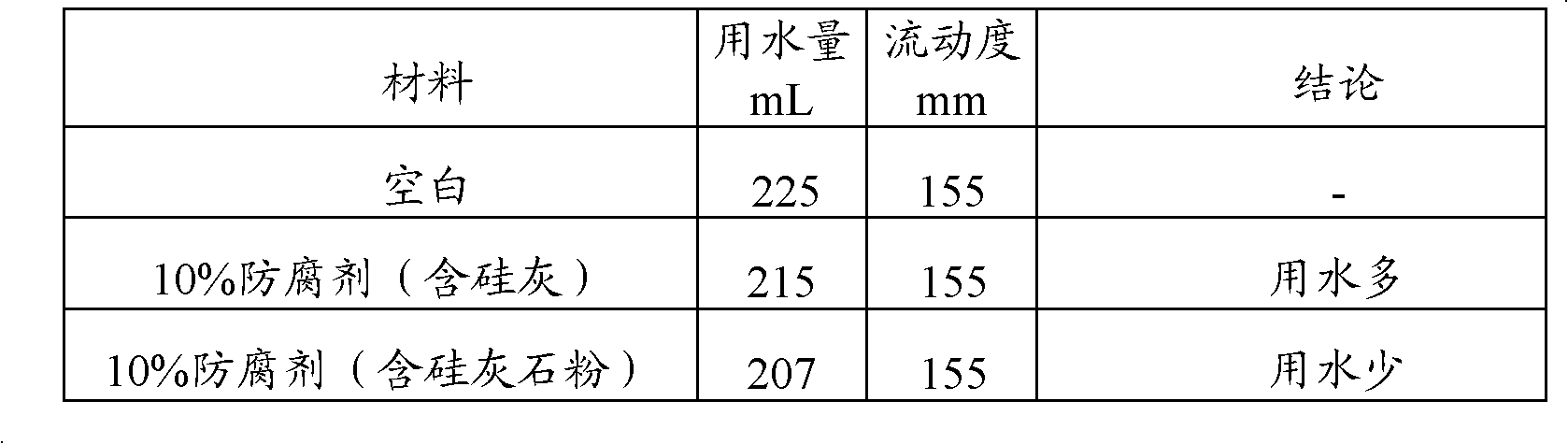

Image

Examples

Embodiment 1

[0083] Prepare concrete anti-corrosion and anti-corrosion agent, the plasticizer in this anti-corrosion and anti-corrosion agent is polycarboxylate powder water reducer, wherein, according to the following component content, prepare materials:

[0084] Wollastonite: 50%; (the specific surface area of wollastonite is: 280m 2 / kg)

[0085] Si-alumina material: 39.3%; (Si-alumina material is dickite, specific surface area 290m 2 / kg)

[0086] Light-burned magnesia: 10%; specific surface area 260m 2 / kg

[0087] Polycarboxylate superplasticizer: 0.7%.

[0088] The above-mentioned materials are mixed in proportion until uniform, and the finished product is obtained.

[0089] The concrete anti-corrosion and anti-corrosion agent which accounts for 10% of the weight of the cementitious material is added, and the anti-corrosion coefficient reaches 1.05. For the definition and measurement method of the corrosion resistance coefficient, refer to the building materials industry st...

Embodiment 2

[0091] Prepare concrete anti-corrosion and anti-corrosion agent, the plasticizer in this anti-corrosion and anti-corrosion agent is sulfamic acid powder water reducer, wherein, prepare materials according to the following component content:

[0092] Wollastonite: 60%; (the specific surface area of wollastonite is: 310m 2 / kg)

[0093] Si-alumina material: 30.5%; (silicon-alumina material is coal gangue with a specific surface area of 275m 2 / kg)

[0094] Light-burned magnesia: 8%; specific surface area 260m 2 / kg

[0095] Sulfamic acid superplasticizer: 1.5%.

[0096] The above-mentioned materials are mixed in proportion until uniform, and the finished product is obtained.

[0097] The concrete anti-corrosion and anti-corrosion agent which accounts for 10% of the weight of the cementitious material is added, and the anti-corrosion coefficient reaches 1.1. For the definition and measurement method of the corrosion resistance coefficient, refer to the building material...

Embodiment 3

[0099] Prepare concrete anti-corrosion and anti-corrosion agent, the plasticizer in this anti-corrosion and anti-corrosion agent is naphthalene series sulfonic acid powder water reducing agent, wherein, prepare materials according to the following component content:

[0100] Wollastonite: 45%; (the specific surface area of wollastonite is: 295m 2 / kg)

[0101] Si-alumina material: 42%; (silicon-alumina material is alumite, with a specific surface area of 280m 2 / kg)

[0102] Light-burned magnesia: 9%; specific surface area 260m 2 / kg

[0103] Naphthalene-based sulfonic acid superplasticizer: 4%.

[0104] The above-mentioned materials are mixed in proportion until uniform, and the finished product is obtained.

[0105] The concrete anti-corrosion and anti-corrosion agent which accounts for 10% of the weight of the cementitious material is added, and the anti-corrosion coefficient reaches 1.0. For the definition and measurement method of the corrosion resistance coeffi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com