Method and device for producing organic fertilizer from organic sludge

An organic sludge and organic fertilizer technology, applied in the preparation of organic fertilizers, organic fertilizers, fertilization devices, etc., can solve the problems of polluting the atmosphere, soil and surrounding environment, secondary pollution of the environment, occupation of land resources, etc., to protect the environment. , the effect of preventing pollution and improving the quality of living environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

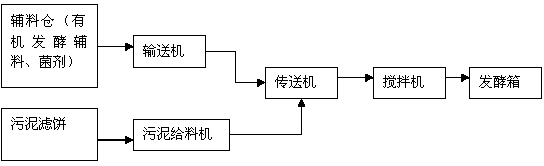

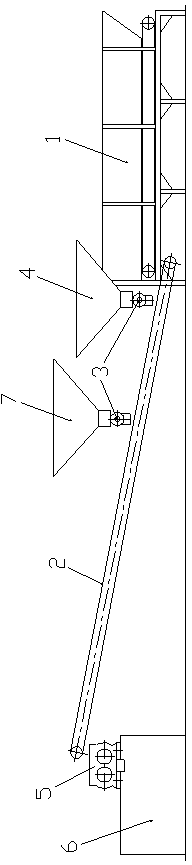

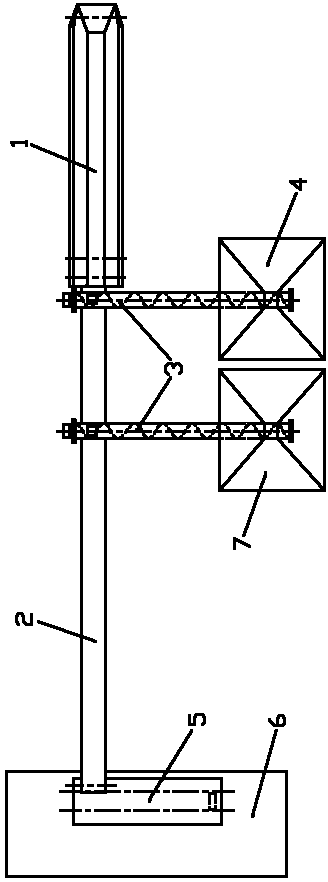

[0014] refer to Figure 1~3 , a kind of method that utilizes organic sludge to make organic fertilizer: preparation weight ratio is the organic fermentation auxiliary material of 20%~50% and the sludge filter cake preparation material of 50%~80%, wherein the water content of organic fermentation auxiliary material is 25% %~50%, the particle size is 10mm~20mm; prepare the bacterial agent, and mix the bacterial agent and organic fermentation auxiliary materials in the auxiliary material bin 4, and the evenly mixed fermentation auxiliary material mixture is transported to the conveyor belt 2 by the screw conveyor 3, and the conveyor belt 2 Transfer the fermentation auxiliary material mixture to the mixer 5; at the same time, the sludge feeder 1 transports the pulverized sludge filter cake to the conveyor belt 2, and the conveyor belt 2 transmits the sludg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com