Cyclically degradable granulated conditioning agent and application of conditioning agent in sludge compost

A conditioner and granulation technology, which is applied in the field of recyclable degradable granulation conditioner, can solve the problems of affecting the quality of compost finished products, prolonging the sludge composting cycle, increasing the cost of sludge composting, etc., and achieving good microbial adhesion and fluidity Good, easy sifting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] Embodiment 1: The recyclable degradable granulated conditioner in this embodiment is a homogeneous woody body with a particle size of 0.5-10 cm.

[0013] In this embodiment, the homogeneous wood body is a sphere or a cube with a particle size of 0.5-10 cm, which is processed by dry wood through crushers, molding machines and other mechanical equipment. The wood homogeneous body has the same particle size and shape, light weight, good fluidity, easy to sieve, recyclable, good water absorption, adjustable moisture, easy to attach microorganisms, recyclable inoculation, degradability, residue does not affect the finished product quality features.

specific Embodiment approach 2

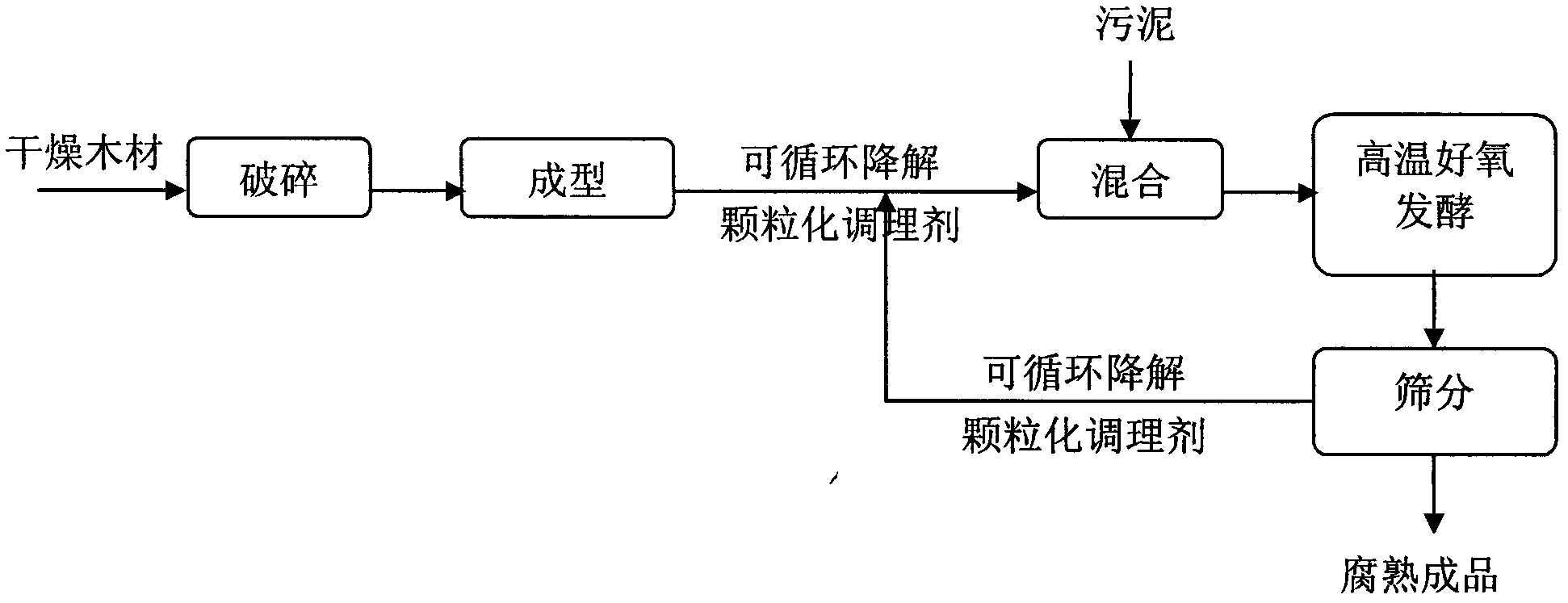

[0014] Specific embodiment two: the application of the recyclable degradable granulation conditioner in this embodiment in sludge composting is as follows: (1) by mass ratio 1: (0.35~1.35) the sludge is mixed with the conditioner to obtain the mixed material, the mixture The moisture content of the material is 55-65%; (2) The mixed material is put into the fermentation facility for high-temperature aerobic fermentation, and the ventilation rate is 0.05-6m 3 / (min·m 3 ), maintaining the temperature of the mixed material at 55°C for at least 5 days; (3) discharging the material after 9 to 20 days of fermentation, and then sieving the conditioner through a drum sieve. Application in composting. Wherein the water content of the sludge in the step (1) is 75-85%, and the organic matter content is 40-85%.

[0015] In this embodiment, if the intermittent dynamic fermentation process is adopted, regular turning and mixing can be carried out, and the turning frequency is 1 to 4 days. ...

specific Embodiment approach 3

[0018] Embodiment 3: This embodiment is different from Embodiment 2 in that the moisture content of the sludge in step (1) is 80%, and the organic matter content is 60%. Other steps and parameters are the same as in the second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com