Organic matter coated urea and production method thereof

A technology for coating urea and a production method, which is applied to fertilizer mixtures, fertilization devices, applications, etc., can solve the problems of unsatisfactory slow-release performance, high requirements for production process conditions, and low fertilizer nitrogen content, and achieves good slow-release effect. , The effect of low production cost and high production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

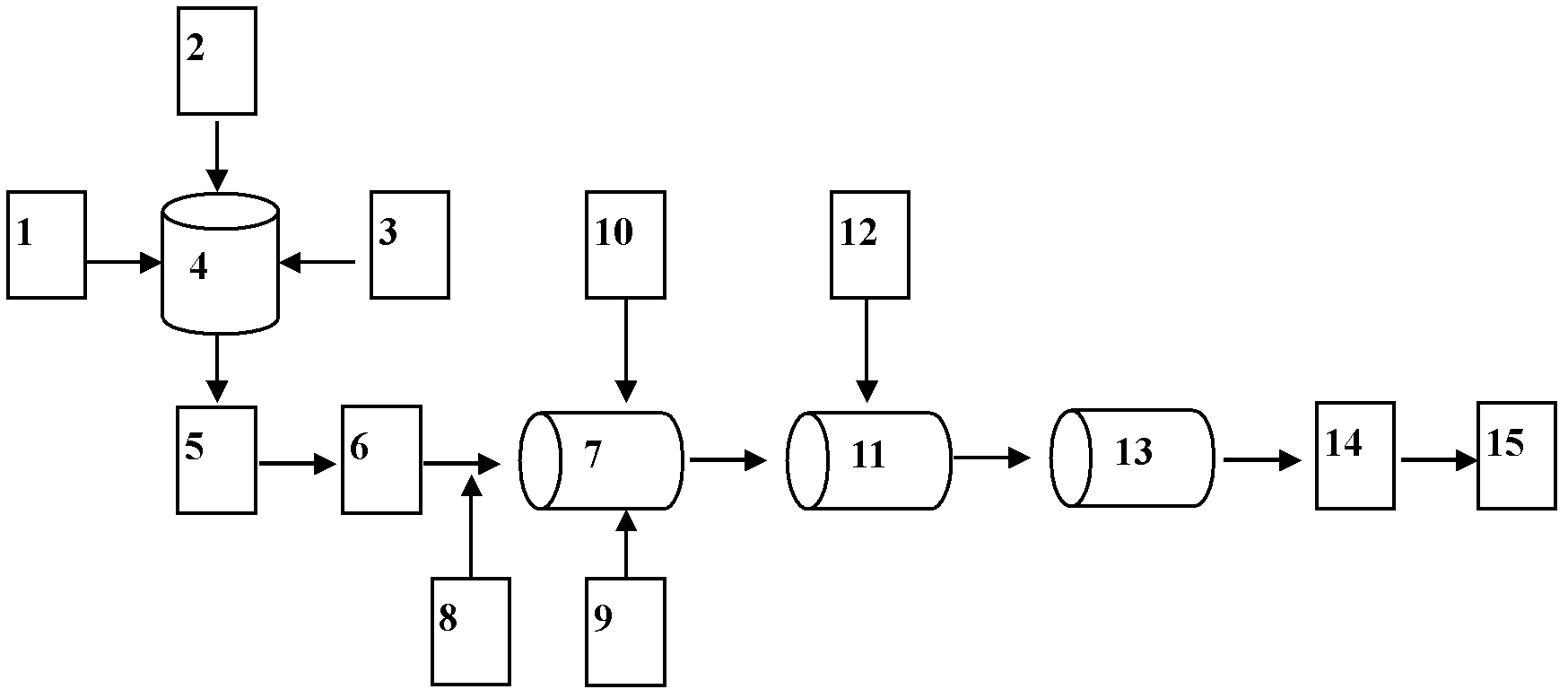

Method used

Image

Examples

Embodiment 1

[0090] Example 1: Preparation of organic coated urea of the present invention.

[0091] The preparation steps are as follows:

[0092] A, preparation of urea-formaldehyde binder

[0093] 1.5 moles of urea and 1 mole of 38% formaldehyde solution by weight are mixed in a reaction kettle sold by Wuxi Xuelang Riveting and Welding Factory Co., Ltd. under the trade name external coil heating stainless steel reactor to obtain a mixture; use 16% NaOH by weight Solution Adjust the pH value of the mixture to 8, then react at a temperature of 94 ° C for 25 min, and then use 14% H by weight after cooling 2 SO 4 The pH value of the aqueous solution was adjusted to 3.5, followed by a constant temperature reaction at a temperature of 68°C for 38 minutes, and then the reactant was dried in an oven produced by Wujiang Dongyuan Electric Heating Equipment Co., Ltd. at a temperature of 80°C, and then crushed to 120 Object, obtain a kind of urea-formaldehyde binding agent;

[0094] B. The ur...

Embodiment 2

[0099] Example 2: Preparation of the organic coated urea of the present invention.

[0100] The preparation steps are as follows:

[0101] A method for producing organic matter coated urea, characterized in that the steps of the method are as follows:

[0102] A, preparation of urea-formaldehyde binder

[0103] 1.6 moles of urea and 1 mole of 38% formaldehyde solution by weight are mixed in a reaction kettle sold by Wuxi Xuelang Riveting and Welding Factory Co., Ltd. under the trade name external coil heating stainless steel reactor; use 16% NaOH by weight Adjust the pH value of the mixture to 8, then react at a temperature of 90°C for 30 minutes, and then use 10% H by weight after cooling 2 SO 4 The pH value of the aqueous solution was adjusted to 4.5, followed by a constant temperature reaction at a temperature of 60°C for 30 minutes, and then the reactant was dried at a temperature of 84°C in an oven produced by Wujiang Dongyuan Electric Heating Equipment Co., Ltd., and ...

Embodiment 3

[0109] Example 3: Preparation of the organic coated urea of the present invention.

[0110] The preparation steps are as follows:

[0111] A method for producing organic matter coated urea, characterized in that the steps of the method are as follows:

[0112] A, preparation of urea-formaldehyde binder

[0113] 1.5 moles of urea and 1 mole of 40% by weight formaldehyde solution are mixed in a reaction kettle sold by Wuxi Xuelang Riveting and Welding Factory Co., Ltd. under the trade name external coil heating stainless steel reactor to obtain a mixture; use 14% by weight of NaOH Solution Adjust the pH value of the mixture to 9, then react at a temperature of 100 ° C for 26 min, and then use 16% H by weight to 2 SO 4 The pH value of the aqueous solution was adjusted to 3.8, followed by a constant temperature reaction at a temperature of 70°C for 34 minutes, and then the reactant was dried in an oven produced by Wujiang Dongyuan Electric Heating Equipment Co., Ltd. at a tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com