Ionic liquid solid acid synthesized by using cycloheximide and heteropoly acid radical and preparation method thereof

A technology of cyclohexyl imine and ionic liquid, which is applied in the field of preparation of ionic liquid-type solid acid, can solve the problems of difficult separation, high production cost, and large amount of catalyst, and achieve the problems of easy dissolution, high catalytic activity, and cost reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

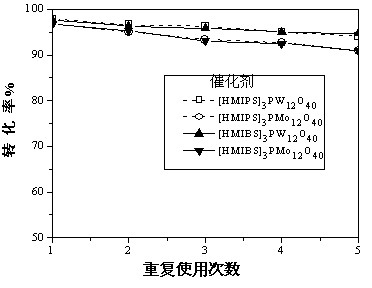

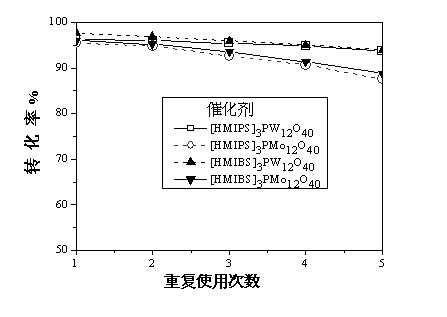

Examples

Embodiment 1

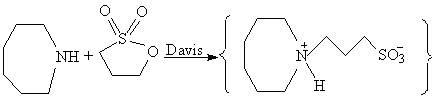

[0027] Step 1: Dissolve 12.215g of 1,3-propane sultone in 100ml of toluene, add 9.915g of cyclohexyl imine dropwise under ice bath and vigorous stirring, and its 1,3-propane sultone and cyclohexyl imine The molar ratio is 1:1. After dropping, react at 30°C, 70°C, and 100°C for 8 hours. The reactant is filtered, and the filter cake is washed with ethyl acetate and ether three times in turn, and dried at 100°C to obtain The masses of the white ionic liquid precursor 1-(propyl-3-sulfonic acid) cycloheximide inner salt (HMI-PS) were 18.60g, 21.47g, and 20.91g, respectively.

[0028] Step 2: Dissolve 6.639g HMI-PS in water, and add 28.80g aqueous solution of dodecatungstophosphoric acid with a molar ratio of 1:3 dropwise at room temperature under electric stirring. After dropping, react at room temperature for 40h. The water was distilled off under reduced pressure at ℃, and the obtained solid was dried at 100 ℃ to obtain a gray-brown ionic liquid-type solid acid 1-(propyl-3-sulfon...

Embodiment 2

[0030] Dissolve 12.215g of 1,3-propane sultone in 150ml of toluene, add 14.873g of cyclohexyl imine dropwise under ice bath and strong stirring, the molar ratio of 1,3-propane sultone to cyclohexyl imine The ratio is 1:1.5, after dropping, react at 30°C, 70°C, and 100°C for 8 hours, the reactant is filtered, the filter cake is washed with ethyl acetate and ether three times in turn, and dried at 100°C to obtain a white ionic liquid The masses of the precursor 1-(propyl-3-sulfonic acid) cycloheximide internal salt (HMI-PS) were 18.80g, 21.77g, and 20.97g, respectively.

[0031] Dissolve 6.639g of HMI-PS in water, and add 57.60g of dodecatungstophosphoric acid aqueous solution with a molar ratio of 1:6 dropwise at room temperature under electric stirring. The water was removed by pressure distillation, and the resulting solid was dried at 100°C to obtain a gray-brown ionic liquid-type solid acid 1-(propyl-3-sulfonic acid)cyclohexylimide dodecatungstophosphate ([HMIPS] 3 PW 12 ...

Embodiment 3

[0033] Step 1: Dissolve 12.215g of 1,3-propane sultone in 100ml of toluene, add 9.915g of equimolar cycloheximide dropwise under ice bath and strong stirring, and react at 70°C for 2h respectively. After 8h and 15h, the reactant was filtered, the filter cake was washed three times with ethyl acetate and diethyl ether in turn, and dried at 100°C to obtain the white ionic liquid precursor HMI-PS with the masses of 16.32g, 21.47g, and 21.55g, respectively. .

[0034] The second step: the same as the second step of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com