Method for preparing magnetic nano carrier immobilized aldolase with high substrate tolerance

A magnetic nanocarrier, resistant technology, applied in the direction of immobilization on or in inorganic carriers, can solve the problem of increased product separation, limited reactant concentration, 2-deoxy-D-ribose-5-phosphate aldol condensation The practical application value of enzymes is reduced, and the effect of improving substrate tolerance, convenient recovery and reuse, and large-scale industrial application value is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

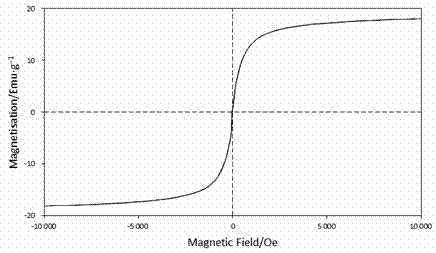

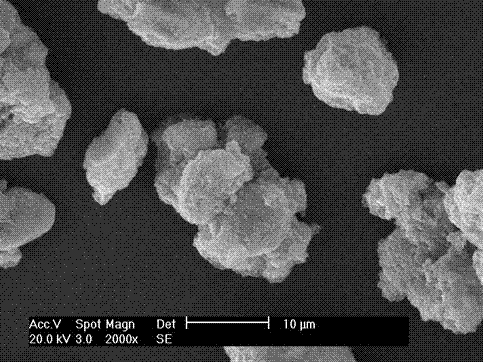

Image

Examples

preparation example Construction

[0015] The steps of the preparation method of the magnetic nanocarrier immobilized aldolase with high substrate tolerance are as follows:

[0016] 1) Add 0.25~0.35mol of ferric salt and 0.15~0.2mol of ferrous salt to 250mL of anaerobic water, adjust to pH = 1~2 with hydrochloric acid, ultrasonically treat for 30-40 min; heat up to 70~85 ℃, Stirring at 1 200~1 400 rpm, N 2 Bubble for 25-30 min, add 9-10 mL of ammonia water with a mass percentage of 25-28% or 10-15 mL of 10mol / L NaOH to make the solution pH = 8-10, after 20-30 min, magnetically separate and wash with anaerobic water 5~10 times, and then washed 3~4 times with 0.010~0.015mol / L ethanol aqueous solution;

[0017] 2) Add 80-100 mL of 50% by volume ethanol aqueous solution, 6-8 mL of silane cross-linking agent, stir at 50-60 °C, 180-220 rpm for 5-6 h, wash with pH = 7 phosphate buffer for 3 ~5 times;

[0018] 3) Add 18-20 mL pH = 7 phosphate buffer solution and 18-20 mL 5% glutaraldehyde aqueous solution, stir at ...

Embodiment 1

[0023] 1) Add 0.25 mol of ferric salt and 0.15 mol of ferrous salt to 250 mL of anaerobic water, adjust to pH = 1 with hydrochloric acid, and sonicate for 30-40 min; 2 Bubble for 25 min, add 9 mL of 25% by mass ammonia water or 10 mL of 10 mol / L NaOH to make the solution pH = 8, after 20 min, magnetically separate, wash with anaerobic water for 5 times, and then wash with 0.010 mol / L ethanol aqueous solution 3 times;

[0024] 2) Add 80 mL of 50% by volume ethanol aqueous solution, 6 mL of silane cross-linking agent, stir at 50°C and 180 rpm for 5 h, and wash with pH = 7 phosphate buffer for 3 times;

[0025] 3) Add 18 mL pH = 7 phosphate buffer and 18 mL 5% glutaraldehyde aqueous solution, stir at 200 rpm for 2 h, magnetically separate, wash 5 times with pH = 7 phosphate buffer, and vacuum dry to obtain Surface-activated magnetic nanoparticle microsphere carrier;

[0026] 4) Prepare 1 mg / ml aldolase protein solution, the mass ratio of aldolase protein to carrier is 1: 1, in...

Embodiment 2

[0029] 1) Add 0.35 mol of ferric salt and 0.2 mol of ferrous salt to 250 mL of anaerobic water, adjust to pH = 2 with hydrochloric acid, and sonicate for 340 min; 2Bubble for 30 min, add 10 mL of 28% by mass ammonia water or 15 mL of 10 mol / L NaOH to make the solution pH = 10, after 30 min, magnetically separate, wash with anaerobic water for 10 times, and then wash with 0.015 mol / L ethanol aqueous solution 4 times;

[0030] 2) Add 100 mL of 50% by volume ethanol aqueous solution, 8 mL of silane crosslinking agent, stir at 60 °C and 220 rpm for 6 h, and wash with pH = 7 phosphate buffer for 5 times;

[0031] 3) Add 20 mL pH = 7 phosphate buffer solution and 20 mL 5% glutaraldehyde aqueous solution, stir at 200 rpm for 3 h, magnetically separate, wash 5 times with pH = 7 phosphate buffer solution, and vacuum dry to obtain Surface-activated magnetic nanoparticle microsphere carrier;

[0032] 4) Prepare 1mg / ml aldolase protein solution, the mass ratio of aldolase protein to car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com