Preparation method of polyurethane elastomeric fiber possessing excellent heat setting performance

A polyurethane elastic and heat-setting technology is applied in the field of preparation of polyurethane elastic fibers, which can solve the problems of complex process and insufficient raw material sources, and achieve the effects of simple process, excellent heat-setting performance and excellent heat-setting property.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

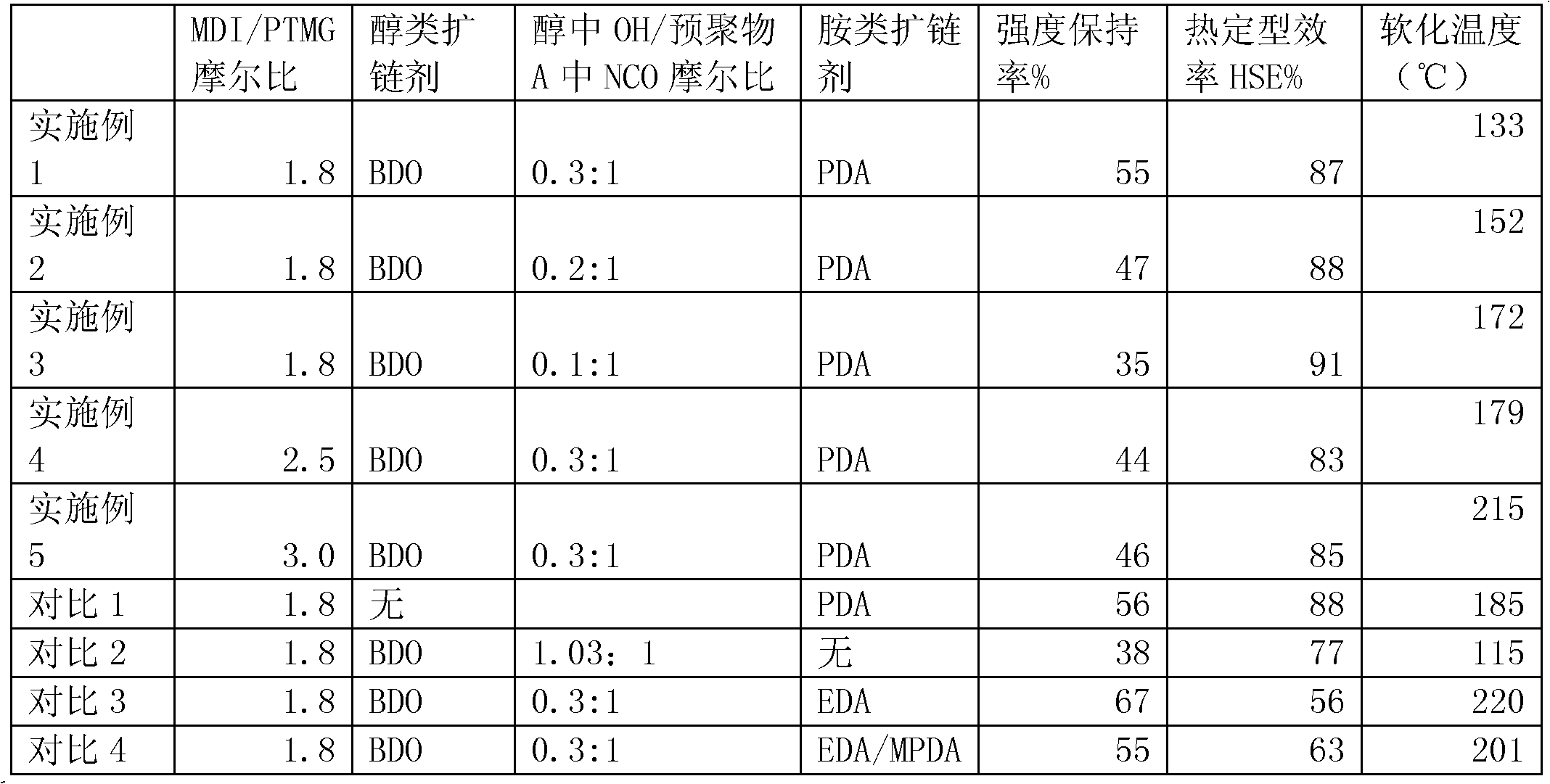

Embodiment 1

[0031] Polytetramethylether glycol (PTMG) with a number average molecular weight of 2000 and 4,4'-diphenylmethylene diisocyanate (MDI) equivalent to 1.8 times its equivalent, under dry nitrogen protection and mechanical stirring, React at 80°C for 3 hours to obtain prepolymer A with -NCO end cap. After cooling down to room temperature, 2.0 wt% 1,4-butanediol (BDO) in N,N-dimethylacetamide solution was added and reacted at 80° C. for 3 hours to obtain NCO-terminated prepolymer B. Wherein, the molar ratio of -OH in the alcohol chain extender to -NCO in the prepolymer A is 0.3:1. After the prepolymer B was lowered to room temperature, N, N-dimethylacetamide was added to dissolve to form a prepolymer B solution.

[0032] The temperature of the above prepolymer B solution was lowered to 10° C., and a DMAC solution of 1,2 propylenediamine and diethylamine mixed amine was added for chain extension to obtain a polyurethane solution. Wherein, the molar ratio of 1,2-propylenediamine:d...

Embodiment 2

[0034] The molar ratio of OH in the alcohol chain extender in Example 1 to NCO in the prepolymer A was adjusted to 0.2:1. The polyurethane solution is prepared by the method of Example 1, and the polyurethane fiber of 22dtex / 2f is dry-spun.

Embodiment 3

[0036] In Example 1, the molar ratio of OH in the alcohol chain extender to NCO in the prepolymer A was adjusted to 0.1:1. The polyurethane solution is prepared by the method of Example 1, and the polyurethane fiber of 22dtex / 2f is dry-spun.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com