Thermal fatigue performance test and analysis method for metal matrix composite material

A composite material and thermal fatigue technology, applied in the direction of analyzing materials, measuring devices, strength characteristics, etc., can solve problems such as failure to consider crack shape, distribution, inaccurate results, large errors, etc., to reduce thermal fatigue failure, operation Simple, error-free effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

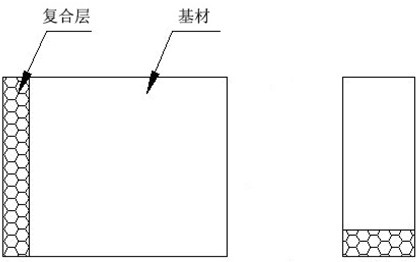

[0022] (1) Cut the Cr15 high-chromium steel-based composite material sample with a volume fraction of tungsten carbide of 20% and a volume fraction of high-carbon ferrochrome powder of 80% into squares, and grind the side with the base material and the composite layer to Polished state;

[0023] (2) Heat the sample obtained in step (1) at a temperature of 600°C for 10 minutes until the sample is fully heated;

[0024] (3) Put the high-temperature sample obtained in step (2) into water at room temperature, and make it chill to room temperature, so as to simulate the working conditions of chilling and chilling;

[0025] (4) Polish the sample cooled in step (3) to remove the surface oxide skin, observe the grinding surface in step (1) with a metallographic microscope, and take pictures of cracks and composite layers;

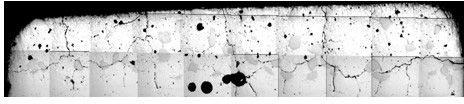

[0026] (5) Repeat steps (2), (3) and (4) 30 times, and take photos (such as image 3 As shown) use the thermal fatigue crack image analysis system to conduct qua...

Embodiment 2

[0029] (1) Cut the Cr15 high-chromium steel-based composite material sample with a volume fraction of tungsten carbide of 40% and a volume fraction of high-carbon ferrochrome powder of 60% into squares, and grind the side with the base material and the composite layer to Polished state;

[0030] (2) Heat the sample obtained in step (1) at a temperature of 800°C for 5 minutes until the sample is fully heated;

[0031] (3) Put the high-temperature sample obtained in step (2) into water at room temperature, and make it chill to room temperature, so as to simulate the working conditions of chilling and chilling;

[0032] (4) Polish the sample cooled in step (3) to remove the surface oxide skin, observe the grinding surface in step (1) with a metallographic microscope, and take pictures of cracks and composite layers;

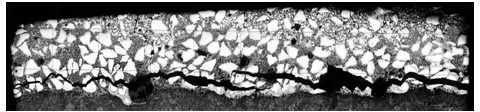

[0033] (5) Repeat steps (2), (3) and (4) 36 times to take the photos (such as Figure 4 Shown) Quantitative analysis of cracks with the thermal fatigue crack imag...

Embodiment 3

[0036] (1) Cut the Cr15 high-chromium steel-based composite material sample with a volume fraction of tungsten carbide of 40% and a volume fraction of high-carbon ferrochrome powder of 60% into squares, and grind the side with the base material and the composite layer to Polished state;

[0037] (2) Heat the sample obtained in step (1) at a temperature of 500°C for 8 minutes until the sample is fully heated;

[0038] (3) Put the high-temperature sample obtained in step (2) into water at room temperature, and make it chill to room temperature, so as to simulate the working conditions of chilling and chilling;

[0039] (4) Polish the sample cooled in step (3) to remove the surface oxide skin, observe the grinding surface in step (1) with a metallographic microscope, and take pictures of cracks and composite layers;

[0040] (5) Repeat steps (2), (3) and (4) 40 times, and use the thermal fatigue crack image analysis system to conduct quantitative analysis of the cracks in the ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com