Method for detecting preheating temperature during welding process

A technology of preheating temperature and detection method, applied in radiation pyrometry, welding equipment, auxiliary welding equipment, etc., to achieve the effect of small investment, flexible installation and deployment, great economic value and environmental protection value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

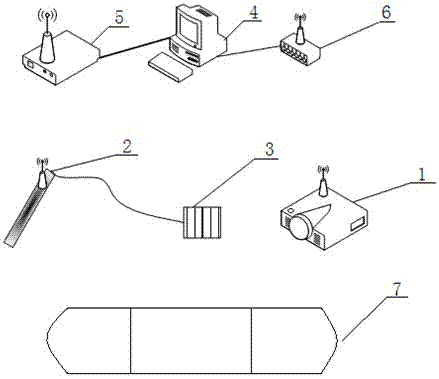

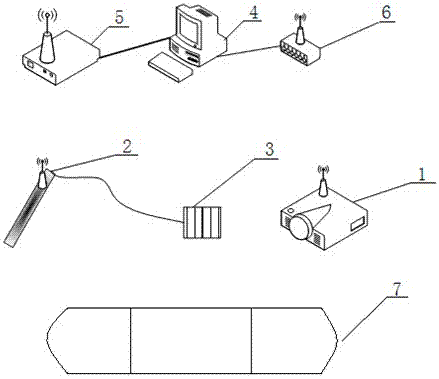

[0014] Such as figure 1 The system block diagram of the preheating temperature detection in the welding process is shown, including a thermal imager with wireless WiFi 1, a wireless infrared thermometer based on IEEE802.15.4 2, a battery pack 3, a computer 4, a wireless WiFi gateway 5, and a wireless infrared thermometer based on IEEE802.15.4 The wireless gateway 6, the welding processing workpiece 7, the wireless sensor network system composed of the thermal imager 1 with wireless WiFi and the wireless infrared thermometer 2 based on IEEE802.15. The imager 1 collects the temperature field data and heat map of the on-site welding and processing workpiece 7 and uploads the information to the wireless WiFi gateway 5 through wireless mode, and the gateway 5 communicates with the computer 4 through wired mode; the wireless infrared thermometer 2 based on IEEE802.15.4 transmits the temperature data through It is uploaded wirelessly to the wireless gateway 6 based on IEEE802.15.4, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com