Temperature fuse capable of being soldered through reflow

A temperature fuse and reflow soldering technology, which is applied in the direction of heating/cooling contact switches, etc., can solve the problems of thermal fuse blown, reflow soldering cannot be used, and chip-based SMD components cannot be realized, so as to improve the qualified rate of finished products and facilitate The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

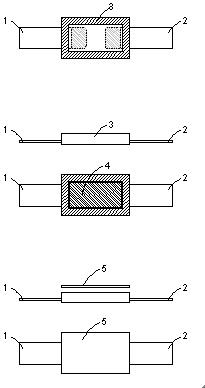

[0030] Such as figure 1 As shown, the pins are made of tin-plated pure nickel material (1, 2), the size is 2.1mm*5mm*0.75mm, the frame-shaped shell size is 3mm*5mm, the material is LCP (3), and the alloy is SnBiIn The alloy material (4) has a size of 3.8mm*1.8mm*0.3mm, the melting point of the alloy is 98°C, and the cover material is a 0.15mm PET sheet (5). The pins are connected to the frame-shaped housing by injection molding, and the tin-plated ends protrude from the middle of the frame-shaped housing and cling to the bottom of the frame-shaped housing, leaving a gap of 1.3mm in the middle. After adding flux to the pin ends, put the small alloy sheet (4), cover the PET sheet (5) on the alloy, and apply a certain pressure. Then it goes through a reflow soldering furnace with a maximum temperature of 265°C. After welding, remove the PET sheet and observe the shape of the alloy sheet (4). Those that are basically not deformed or slightly thinner are qualified, and those that...

Embodiment 2

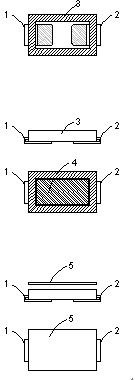

[0035] Such as figure 2 As shown, the pins are made of tin-plated pure nickel material (1, 2), and the size is 2.1mm*5mm*0.75mm. The gap with Al2O3 is sealed with epoxy resin. The alloy adopts SnBi alloy material (4), the size is 3.8mm*1.8mm*0.3mm, the alloy melting point is 139°C, and the cover plate material adopts 0.15mm PA sheet (5). The pins are connected to the frame-shaped housing by injection molding, and the tin-plated ends protrude from the middle of the frame-shaped housing and cling to the bottom of the frame-shaped housing, leaving a gap of 1.3mm in the middle. After adding flux to the pin ends, put the small alloy sheet (4), cover the PET sheet (5) on the alloy, and apply a certain pressure. Then it goes through a reflow soldering furnace with a maximum temperature of 265°C. After welding, remove the PET sheet and observe the shape of the alloy sheet (4). Those that are basically not deformed or slightly thinner are qualified, and those that are broken or be...

Embodiment 3

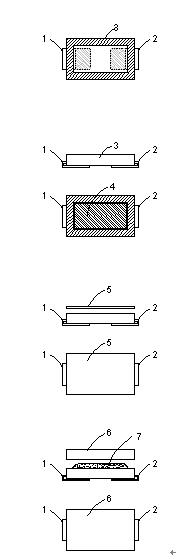

[0040] Such as image 3As shown, the pins are made of tin-plated pure nickel material (1, 2), and the size is 2.1mm*5mm*0.75mm. The gap with Al2O3 is sealed with epoxy resin. The alloy adopts SnBi alloy material (4), the size is 3.8mm*1.8mm*0.3mm, the alloy melting point is 139°C, and the cover plate material adopts 0.15mm PA sheet (5). The pins are connected to the frame-shaped housing by injection molding, and the tin-plated ends protrude from the middle of the frame-shaped housing and cling to the bottom of the frame-shaped housing, leaving a gap of 1.3mm in the middle. After adding flux to the pin ends, put the small alloy sheet (4), cover the PET sheet (5) on the alloy, and apply a certain pressure. Then it goes through a reflow soldering furnace with a maximum temperature of 265°C. After welding, remove the PET sheet and observe the shape of the alloy sheet (4). Those that are basically not deformed or slightly thinner are qualified, and those that are broken or becom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com