Micro-pill and preparation method thereof

A technology of pellets and formulations, which is applied in the direction of making medicines into special physical or taking form devices, block delivery, etc., which can solve problems such as adding surfactants.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Embodiment 1: the main factor that affects the forming of pill core containing medicine

[0116] In this example, in the case of the selected drug, the solubility of the active ingredient (vitamin C (0.2g / ml, easily soluble), sarcogrelate hydrochloride (0.02g / ml, slightly soluble)), the excipient (microcrystalline cellulose), wetting agent (20% ethanol), surfactant (polysorbate 80), wetting time of soft material (min), extrusion frequency (HZ), sieve aperture (mm), 9 variables such as spheronization time (min), drying temperature (°C) and 2 dummy variables (Dummy) were used in the P-B experimental design (N=12) to investigate the main factors affecting the pellet formation. Wherein, the amount of the active ingredient is the weight ratio of the active ingredient to (the sum of the active ingredient and the excipient), and the amount of the excipient is the weight ratio of the excipient to the (the sum of the active ingredient and the excipient). The amount of agent is ...

Embodiment 2

[0128] Embodiment 2, the main factor that influences blank ball core forming

[0129] In the present embodiment, the formula composed of 3 factors of excipient type, surfactant (polysorbate 80), and sieve plate aperture is selected to carry out 3-level orthogonal experiment (L 9 (3 4 )), wherein, the weight part of the excipient is 1, the weight part of the wetting agent is 0.8, the weight of the surfactant is the weight percentage of the excipient, and the amount of the three factors is enlarged or reduced year-on-year; the preparation process is shown in "implementation Example Explanation"; the factors and levels are shown in Table 4-1, the arrangement of experiments and experimental results are shown in Table 4-2, and the microphotographs of blank pellet cores obtained in each experiment are shown in Table 4-1. Figures 1-1 to 1-9 shown.

[0130] Table 4-1: L9(3 4 ) factor and level table

[0131]

[0132] Table 4-2: L 9 (3 4 ) to arrange experiments, experiment r...

Embodiment 3

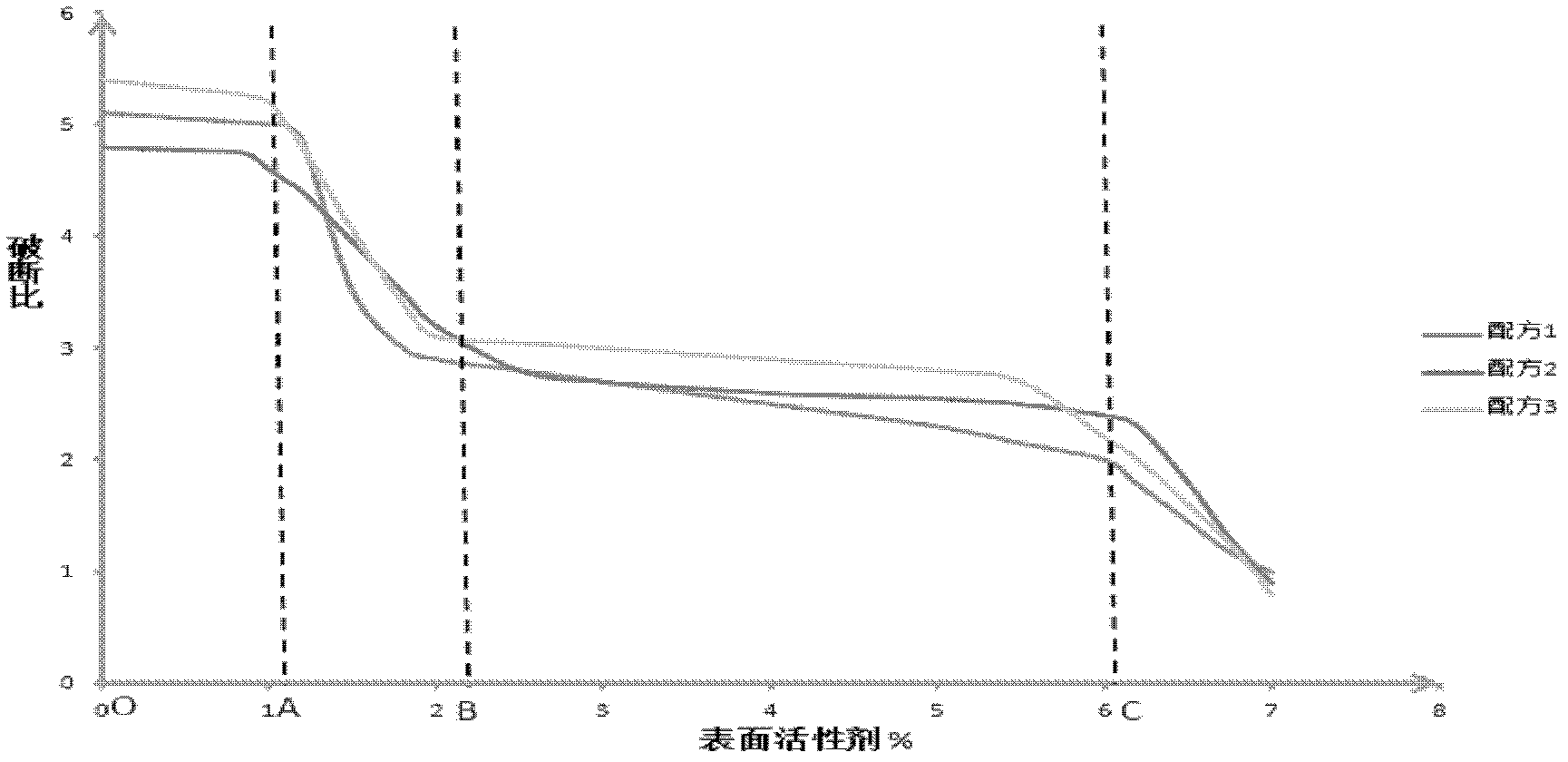

[0135] Embodiment 3: The impact of surfactant on the important process in pellet processing

[0136]In the present embodiment, vitamin C (easy to dissolve), taurine (dissolved), and ambroxol hydrochloride (slightly soluble) are respectively used as active ingredients with microcrystalline cellulose (excipient), 20% ethanol (moisturizing wet agent) to form the base formula, and in each base formula, adding and (the sum of active ingredient and excipient) weight percentage are 0, 1, 2, 3, 4, 6, 7% surfactant (polysorbate Ester 80, HLB: 15) form a series of formulas (the active ingredient of formula 1 is vitamin C, the active ingredient of formula 2 is taurine, and the active ingredient of formula 3 is ambroxol hydrochloride), according to the "preparation method" in "Example Description" " and "Procedure Parameters" to prepare bars, observe and calculate the shape of the bars and the yield per unit time, and drop the bars naturally into a 1-meter square plate, and transfer them ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com