Preparation method of monodisperse spherical porous palladium nano catalyst

A palladium nano- and monodisperse technology is applied in the field of preparation of nano-catalysts, which can solve problems such as inability to completely remove and affect catalytic applications, and achieve the effects of saving preparation costs, good prospects for industrial application and good controllability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of monodisperse spherical porous palladium nanocatalyst: While vigorously stirring, add K 2 PdCl 4 Ascorbic acid solution (10-15mM) was added dropwise to the solution (2-4mM, 5mL) in an amount of 1-2mL. The prepared mixed solution was magnetically stirred (12000r / min) in an ice-water bath for 5-10min. Subsequently, the reaction solution was put into a 3 L ultrasonic cleaner, and the water temperature was kept at 40 °C. The ultrasonic reaction was carried out for 6 or 7 minutes (longer time is also acceptable), and the color of the solution turned brownish black. Separation by centrifugation (12000r / min, 5min), repeated washing with deionized water, and finally drying under vacuum or airflow protection for 6-7 hours (longer time is also acceptable) to obtain the product.

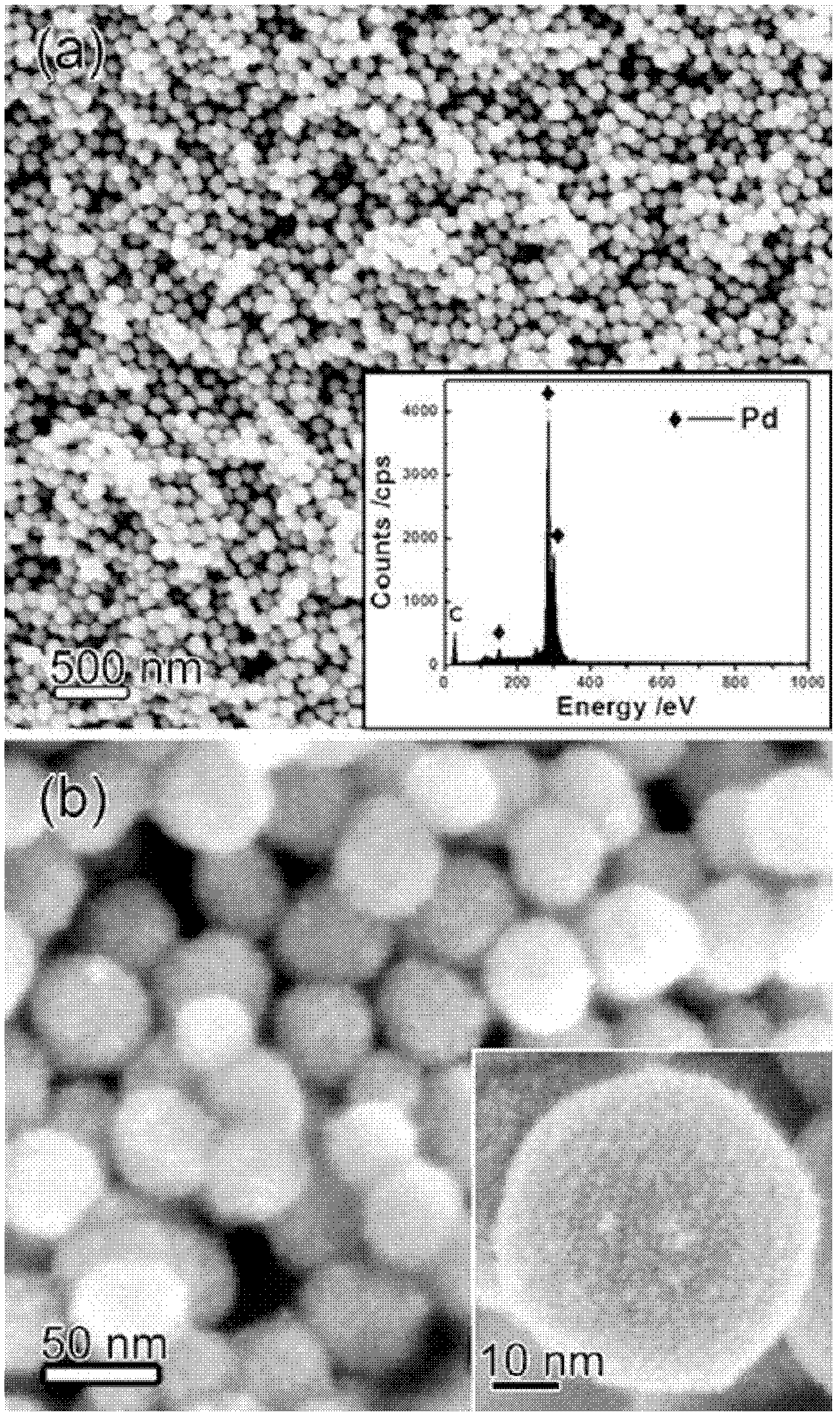

[0036] figure 1 For the SEM picture of the resulting product, it can be seen that the product is made of spherical particles without other by-products ( figure 1 a). Further enlarged ...

Embodiment 2

[0040] Change K 2 PdCl 4 The concentration of the solution was 1.25mM, and other conditions were the same as in Example 1.

Embodiment 3

[0042] Change K 2 PdCl 4 The concentration of the solution was 5.0 mM, and other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com