Method for melting copper at low temperature and copper melting device

A copper-dissolving and low-temperature technology, applied in the field of electrolysis, can solve the problems of declining market competitiveness of enterprises, large corrosion of equipment and pipelines, and high cost of copper foil products, achieving high copper-dissolving efficiency, low equipment investment cost, and easy industrialization The effect of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

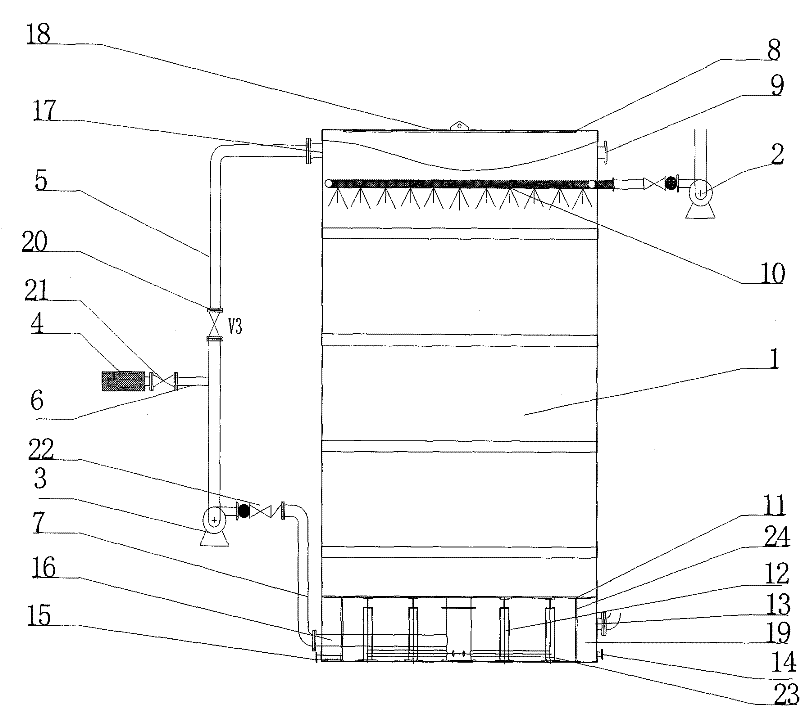

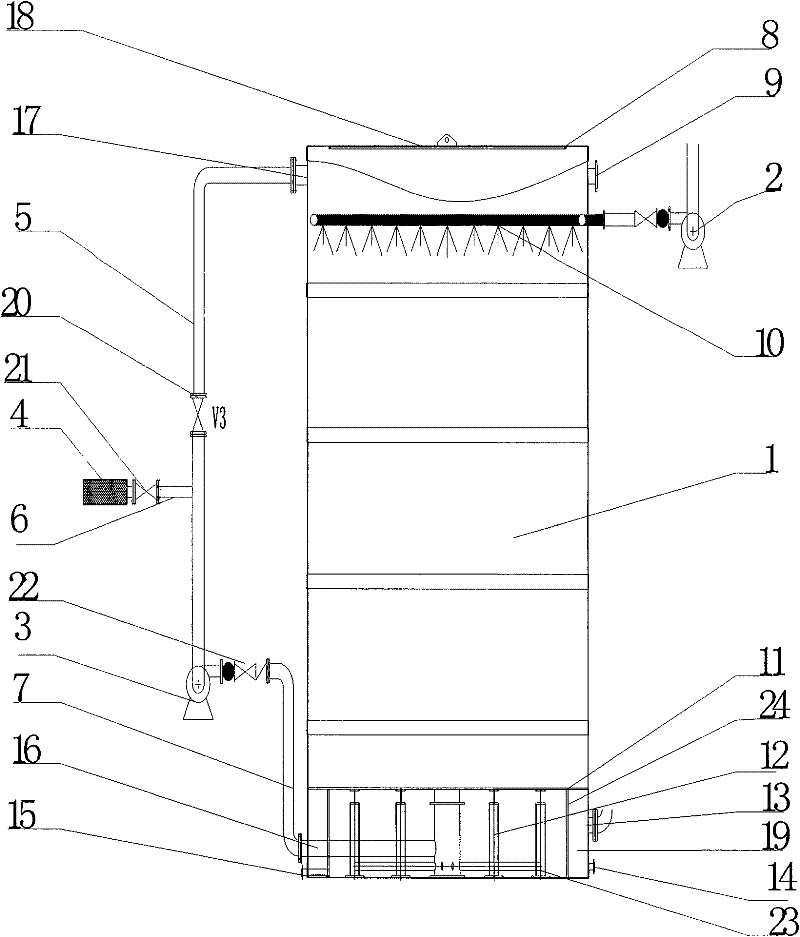

[0025] refer to figure 1 , a method for dissolving copper at low temperature, comprising a copper dissolving device, the copper dissolving device comprising a copper dissolving tank 1, a circulation pipeline 5, an air filter 4, an air pipeline 6, an air intake pipeline 7, and a high-pressure acid-resistant air pump 3 , a liquid level sensor 14, an acid-resistant pump 2, and the described copper-dissolving tank is successively provided with a feeding port 18, an acid-spraying pipe 10 with a plurality of nozzles, and a filter plate 11 from top to bottom, and the acid-spraying pipe 11 passes through and The acid-resistant water pump 2 is connected, and the upper and lower ends of the copper-dissolving tank 1 are sequentially provided with an exhaust port 9 and an air inlet 16, which specifically includes the following steps:

[0026] 1) Prepare reaction raw materials: prepare dilute sulfuric acid solution and prepare copper material;

[0027] 2) Use a preheater to preheat the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com