Method for preparing zirconium oxide ceramic by recycling zirconium oxide ceramic grinding wastes

A zirconia ceramics, grinding processing technology, applied in the field of structural ceramics, can solve problems such as waste of resources, stacking or impact on the surrounding environment of landfill sites, and achieve the effects of saving resources, creating economic value, and simple and easy process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Step 1: Pass the collected yttrium oxide zirconium ceramic grinding waste slurry through a 100-mesh sieve, take the slurry under the sieve and let it stand, discard the supernatant, and keep the wet material for later use.

[0030] Step 2: Take 134g of wet material, which contains 96.8g of zirconia, 1.5g of yttrium oxide, 1.7g of organic matter, 0.5g of metal, and 33.4g of water content. Add 50ml of nitric acid with a concentration of 0.5mol / L, mix and stir, and react at a temperature of 55°C until complete.

[0031] Step 3: Filter the slurry reacted with nitric acid and wash it with pure water.

[0032] Step 4: Add 0.5g of yttrium oxide to adjust the powder composition, mix evenly, burn at 1050°C, and then pulverize into D 50 =0.42μm powder.

[0033] Step 5: The powder obtained in Step 4 is injection-molded into a watch chain green body, which is degreased, sintered and polished to make a zirconium ceramic wear-resistant watch chain. The relevant test data of the pr...

Embodiment 2

[0035] Step 1: Pass the collected yttrium oxide zirconium ceramic grinding waste slurry through a 150-mesh sieve, take the slurry under the sieve and let it stand, discard the supernatant, and keep the wet material for later use.

[0036] Step 2: Take 144g of wet material, which contains 94.4g of zirconia, 3.5g of yttrium oxide, 1.8g of organic matter, 0.5g of metal, and 43g of water content. Add 50ml of hydrochloric acid with a concentration of 1.0mol / L and 5ml of hydrogen peroxide, mix and stir, and react at a temperature of 65°C until complete.

[0037] Step 3: filter the reacted slurry and wash it with pure water.

[0038] Step 4: Add 2g of praseodymium oxide, 1g of cerium oxide, 3g of gadolinium oxide and 10g of alumina and mix evenly to adjust the powder composition, then burn it at 1080°C and pulverize it, and finally granulate it into D 50 =5.1 μm powder.

[0039] Step 5: Injection molding the powder obtained in Step 4 into a grinding medium green body, which is degr...

Embodiment 3-8

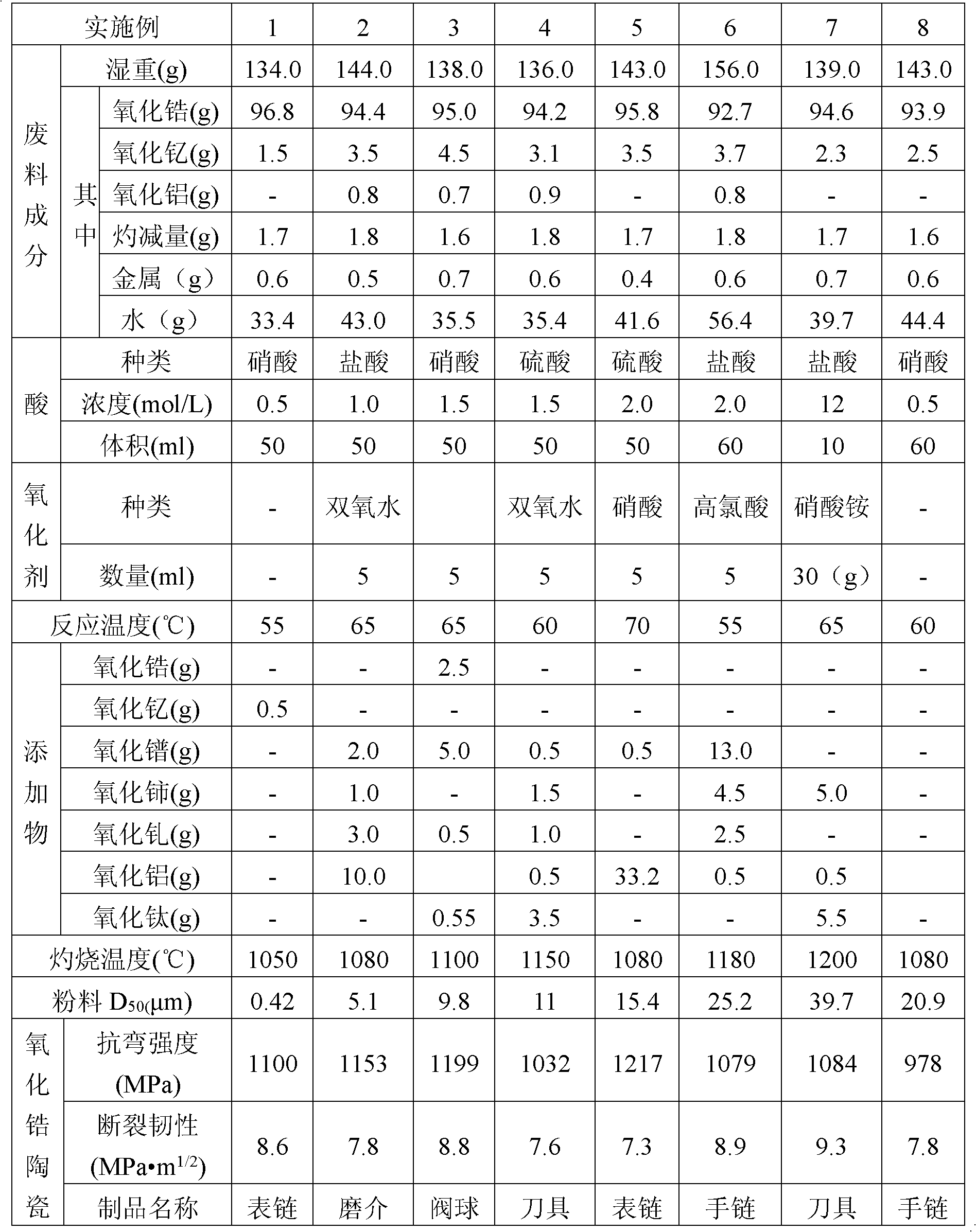

[0041] Each step of embodiment 3-8 is identical with embodiment 2. Waste composition, type and amount of acid, type and amount of oxidant,

[0042] The reaction temperature, firing temperature, and related test data of zirconia ceramic products are detailed in Table 1 below.

[0043] Table 1

[0044]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com