Glycine-doped MgB2 superconductor with high critical current density and preparation method thereof

A glycine and superconductor technology, applied in the field of superconductivity, can solve the problem of sacrificing the connectivity between grains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0018] Weigh Mg powder and B powder according to the atomic ratio of 1:2, then add glycine with a mass fraction of 2%, and grind it in an agate mortar for 30 minutes to make it fully mixed to obtain MgB 2 +2wt% Gly mixed powder. Press the mixed powder into a cylindrical sheet under a pressure of 2MPa, and then put it into a high-temperature differential scanning calorimeter or a tube sintering furnace for sintering; continuously heat at a heating rate of 5°C / min to 750°C for sintering and keep it warm 0.5 hours, and then lowered to room temperature at a cooling rate of 30°C / min.

example 2

[0020] Weigh Mg powder and B powder according to the atomic ratio of 1:2, then add glycine with a mass fraction of 5%, and grind it in an agate mortar for 30 minutes to make it fully mixed to obtain MgB 2 +5wt% Gly mixed powder. Press the mixed powder into a cylindrical sheet under a pressure of 5 MPa, and then put it into a high-temperature differential scanning calorimeter or a tube sintering furnace for sintering; continuously heat at a heating rate of 10°C / min to 800°C for sintering and keep it warm 0.8 hours, and then cooled down to room temperature at a cooling rate of 35°C / min.

example 3

[0022] Weigh Mg powder and B powder according to the atomic ratio of 1:2, then add glycine with a mass fraction of 8%, and grind it in an agate mortar for 30 minutes to make it fully mixed to obtain MgB 2 +8wt% Gly mixed powder. Press the mixed powder into a cylindrical sheet under a pressure of 10MPa, and then put it into a high-temperature differential scanning calorimeter or a tube sintering furnace for sintering; continuously heat at a heating rate of 20°C / min to 800°C for sintering and keep it warm 1 hour, and then cooled down to room temperature at a cooling rate of 40°C / min.

[0023] The effect description is as follows:

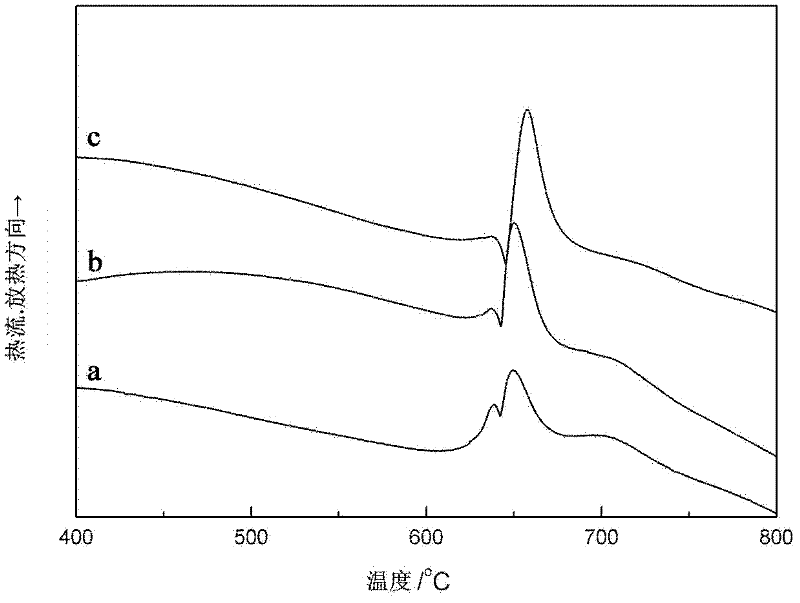

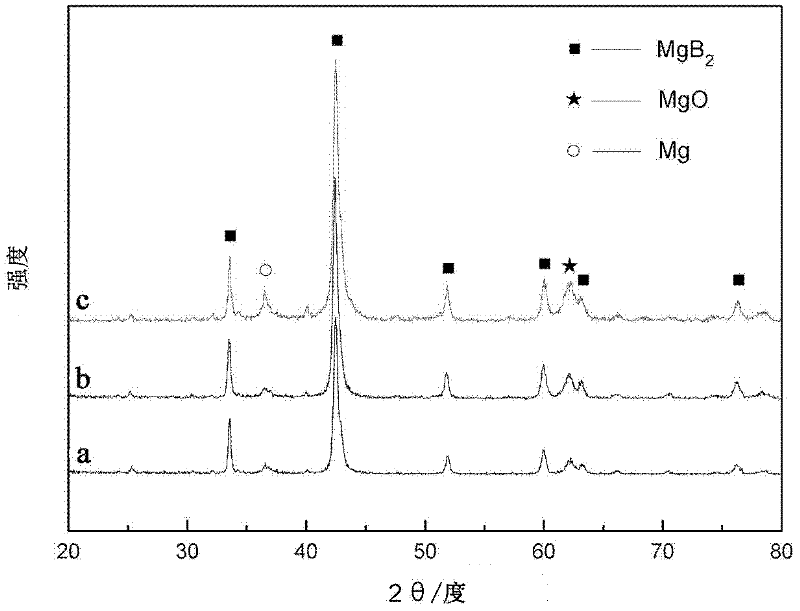

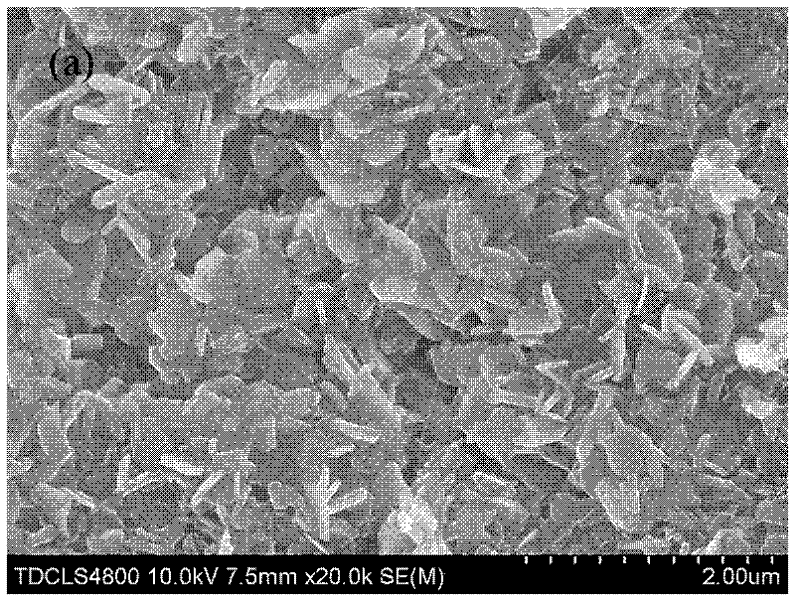

[0024] Weigh the Mg powder and B powder according to the atomic ratio of 1:2, then dope the glycine particles with a mass fraction of 2-8%, and grind them in an agate mortar for 30 minutes to make them fully mixed to obtain MgB 2 +(2~8)% Gly mixed powder. Press the mixed powder into a cylindrical sheet under a pressure of 2-10MPa, and then put it i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com