Preparation method of tl-2223 superconducting thin film

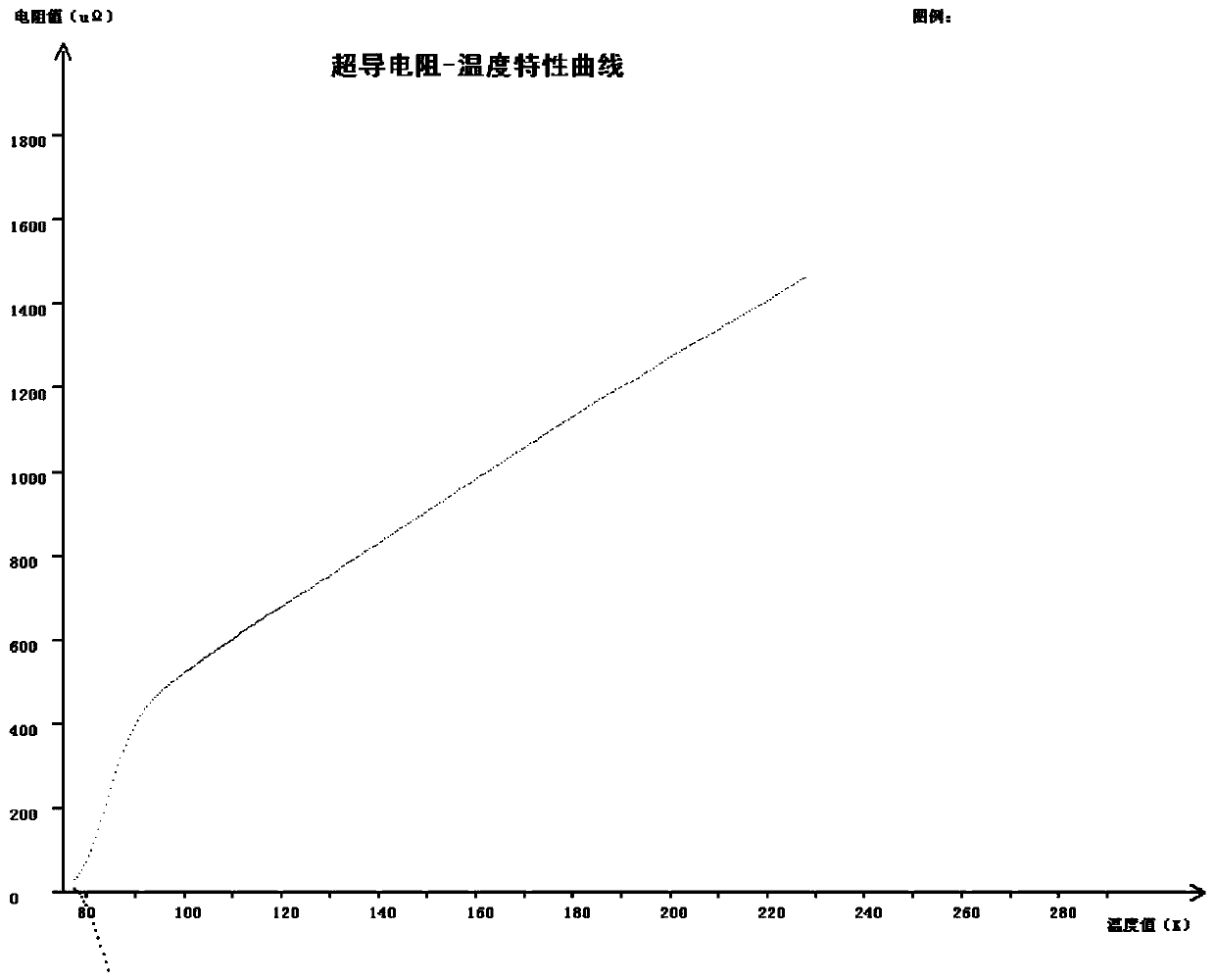

A tl-2223, superconducting thin film technology, applied in the manufacture/processing of superconductor devices, superconducting devices, superconductor components, etc., can solve the problem of long time in the phase temperature zone, increased preparation cycle, and increased production costs and other problems, to achieve the effect of short preparation time, shortening the heating and cooling time and constant temperature time, and avoiding film cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A kind of preparation method of Tl-2223 superconducting film, substrate is CeO 2 / sapphire, including:

[0037] Step 1. Preparation of thallium-containing amorphous precursor film by sol-gel method: use thallium, barium, calcium, copper acetate as

[0038] The starting material is to prepare sol with propionic acid, lactic acid, diethylenetriamine, methanol, etc. as complexing agent and solvent; 2 Prepare a gel film on the sapphire substrate of the isolation layer, and obtain a precursor film through drying and thermal decomposition processes. The molar ratio of Tl, Ba, Ca, and Cu metal ions in the precursor film is 2.4:2:2:3.2;

[0039] Step 2. Preparation of thallium-containing burning target: BaO with a metal ion molar ratio of Ba:Ca:Cu=2:1:2 2 , CaO and CuO as the starting materials are mixed and ground, kept at a constant temperature of 890-940°C for 4 hours in a flowing oxygen environment, crushed and ground after cooling, repeated sintering once, and added Tl ...

Embodiment 2

[0044] A kind of preparation method of Tl-2223 superconducting film, substrate is CeO 2 / sapphire, including:

[0045] Step 1. Preparation of thallium-containing amorphous precursor film by sol-gel method: starting materials of thallium, barium, calcium, copper acetate, propionic acid, lactic acid, diethylenetriamine, methanol, etc. Complexing agent and solvent prepare sol; With this sol has CeO 2 A gel film is prepared on the sapphire substrate of the isolation layer, and a precursor film is obtained through drying and thermal decomposition processes. The metal ion molar ratio of Tl, Ba, Ca, and Cu in the precursor film is 4.5:2:2:3.8;

[0046] Step 2. Preparation of a thallium-containing burner target: BaO with a metal ion molar ratio of Ba:Ca:Cu=2:2:3 2 , CaO and CuO as the starting materials are mixed and ground, kept at a constant temperature of 890-940°C for 8 hours in a flowing oxygen environment, crushed and ground after cooling, repeated sintering once, and added Tl...

Embodiment 3

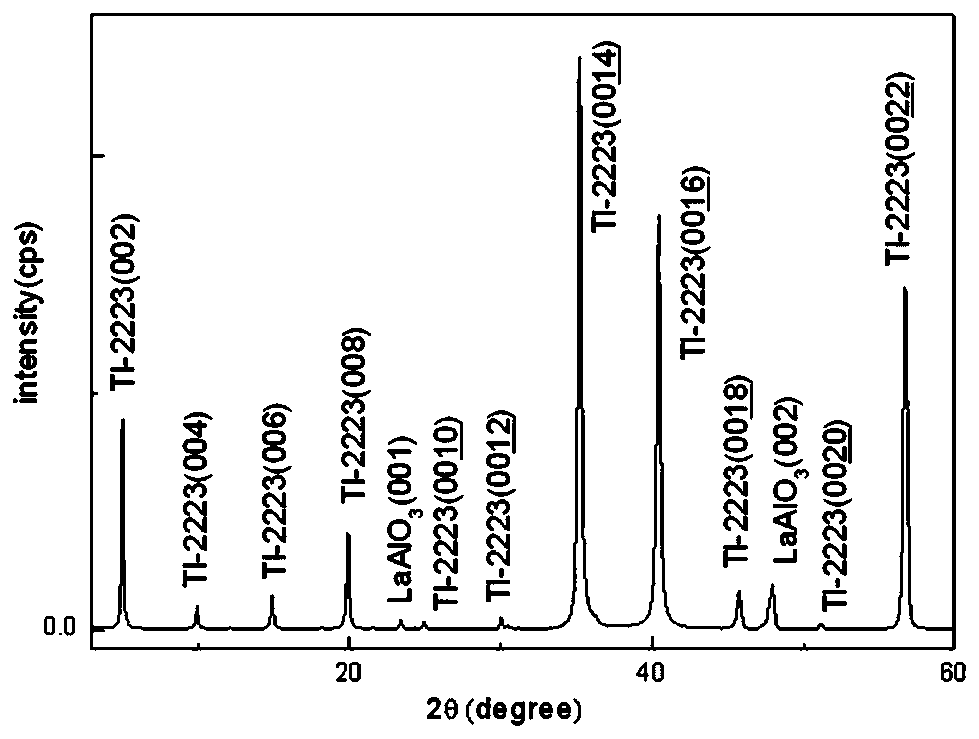

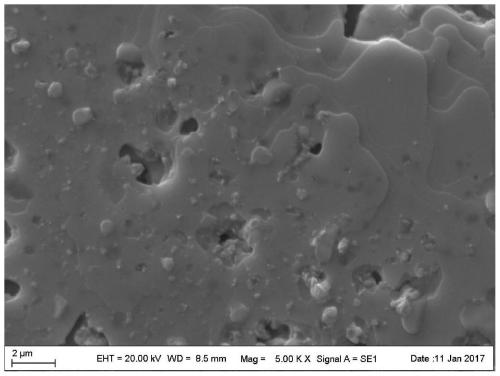

[0050] A kind of preparation method of Tl-2223 superconducting film, substrate is lanthanum aluminate, comprising:

[0051] Step 1. Preparation of an amorphous precursor film containing thallium: BaO with a metal ion molar ratio of Ba:Ca:Cu=2.6:2:3.4 2 or BaO, CaO or CaCO 3 Mix and grind with CuO as the starting material, keep the temperature at 890-940°C for 6h in the flowing oxygen environment, add Tl 2 o 3 Mix and grind the tablets so that the molar ratio of Tl and Ca is Tl:Ca=3.5:2, put them into a sealed crucible, put them together in a sealed quartz tube, and keep the temperature at 850-900°C for 3 hours in a sealed oxygen environment. After cooling, the sputtering target is obtained; radio frequency magnetron sputtering is used for the sputtering target, and the sputtering gas is high-purity Ar or Ar / O 2 Mixed gas, the sputtering pressure is 2-8Pa, and the sputtering power is 45W; the metal ion molar ratio of Tl, Ba, Ca, and Cu in the prepared precursor film is 3.5:2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com