Special controlled slow release fertilizer for dry land sugarcane

A controlled slow-release fertilizer and sugarcane technology, which is applied in the field of dryland sugarcane controlled slow-release fertilizer, can solve the problems of low benefit, restriction of sugarcane, and high input of dryland sugarcane, so as to promote the growth of sugarcane, reduce adverse effects, and increase sugarcane yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

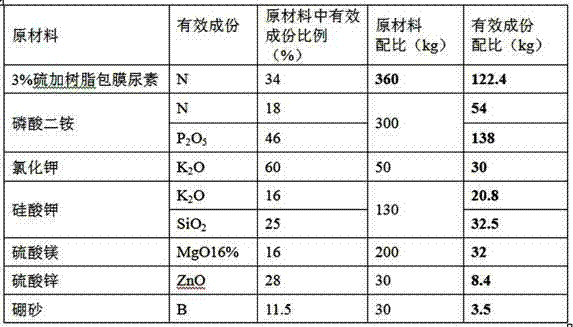

[0031] Basic type The formula of sugarcane controlled slow-release fertilizer:

[0032]

[0033] All raw materials used are commercially available products, wherein 3% sulfur plus resin-coated urea means that the resin film quality is 3% of the total mass, and the sulfur film quality is 20% of the total mass, wherein the mass percentage of N, P, and K is 34% , 0, 0.

[0034] The above-mentioned raw materials are put into a mixer and mixed evenly to form a basal fertilizer type sugarcane controlled slow-release fertilizer granule product with a particle size of 2 to 4 mm.

[0035] The mass percentages of effective elements in the base fertilizer type sugarcane controlled slow-release fertilizer in the present embodiment are: nitrogen 15.3%, phosphorus pentoxide 17.8%, potassium oxide 6.5%, silicon dioxide 2.6%, magnesium oxide 2.4%, zinc oxide 0.6%, boron 0.1%.

[0036] Formula of topdressing sugarcane controlled slow-release fertilizer:

[0037]

[0038] All raw mate...

Embodiment 2

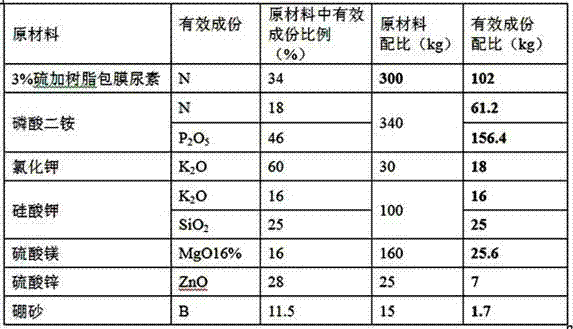

[0044] Formula of base fertilizer sugarcane controlled slow-release fertilizer:

[0045]

[0046] The raw materials used are the same as in Example 1, and the above-mentioned raw materials are put into a mixer and mixed evenly to form a base fertilizer type sugarcane controlled slow-release fertilizer granule product with a particle size of 2 to 4 mm.

[0047] The mass percent of the effective elements of the base fertilizer type sugarcane controlled slow-release fertilizer in the present embodiment is: nitrogen 16.8%, phosphorus pentoxide 16.1%, potassium oxide 3.5%, silicon dioxide 2.6%, magnesium oxide 2.6%, oxidation Zinc 0.7%, boron 0.2%.

[0048] Formula of topdressing sugarcane controlled slow-release fertilizer:

[0049]

[0050] The raw materials used are the same as in Example 1, and the above raw materials are put into a mixer and mixed evenly to form a topdressing type sugarcane controlled slow-release fertilizer granule product with a particle size of 2 to ...

Embodiment 3

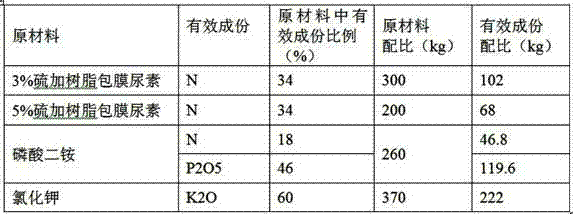

[0054] Formula of base fertilizer sugarcane controlled slow-release fertilizer:

[0055]

[0056] The raw materials used are the same as in Example 1, and the above raw materials are put into a mixer and mixed evenly to form a base fertilizer type sugarcane controlled slow-release fertilizer granule product with a particle size of 2 to 4 mm.

[0057] The mass percentages of effective elements in the base fertilizer type sugarcane controlled slow-release fertilizer in the present embodiment are: nitrogen 16.0%, phosphorus pentoxide 12.5%, potassium oxide 4.6%, silicon dioxide 3.0%, magnesium oxide 2.9%, zinc oxide 0.8%, boron 0.3%.

[0058] Formula of topdressing sugarcane controlled slow-release fertilizer:

[0059]

[0060] The raw materials used are the same as those in Example 1, and the above raw materials are put into a mixer and mixed evenly to form a topdressing type sugarcane controlled slow-release fertilizer granule product with a particle size of 2-4 mm.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com